Integrated pressure reducing valve

A pressure reducing valve and valve body technology, applied in the direction of valve details, safety valves, balance valves, etc., can solve the problems of large size, long response time, high safety requirements, etc., achieve stable outlet pressure, improve pressure regulation, and compact structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

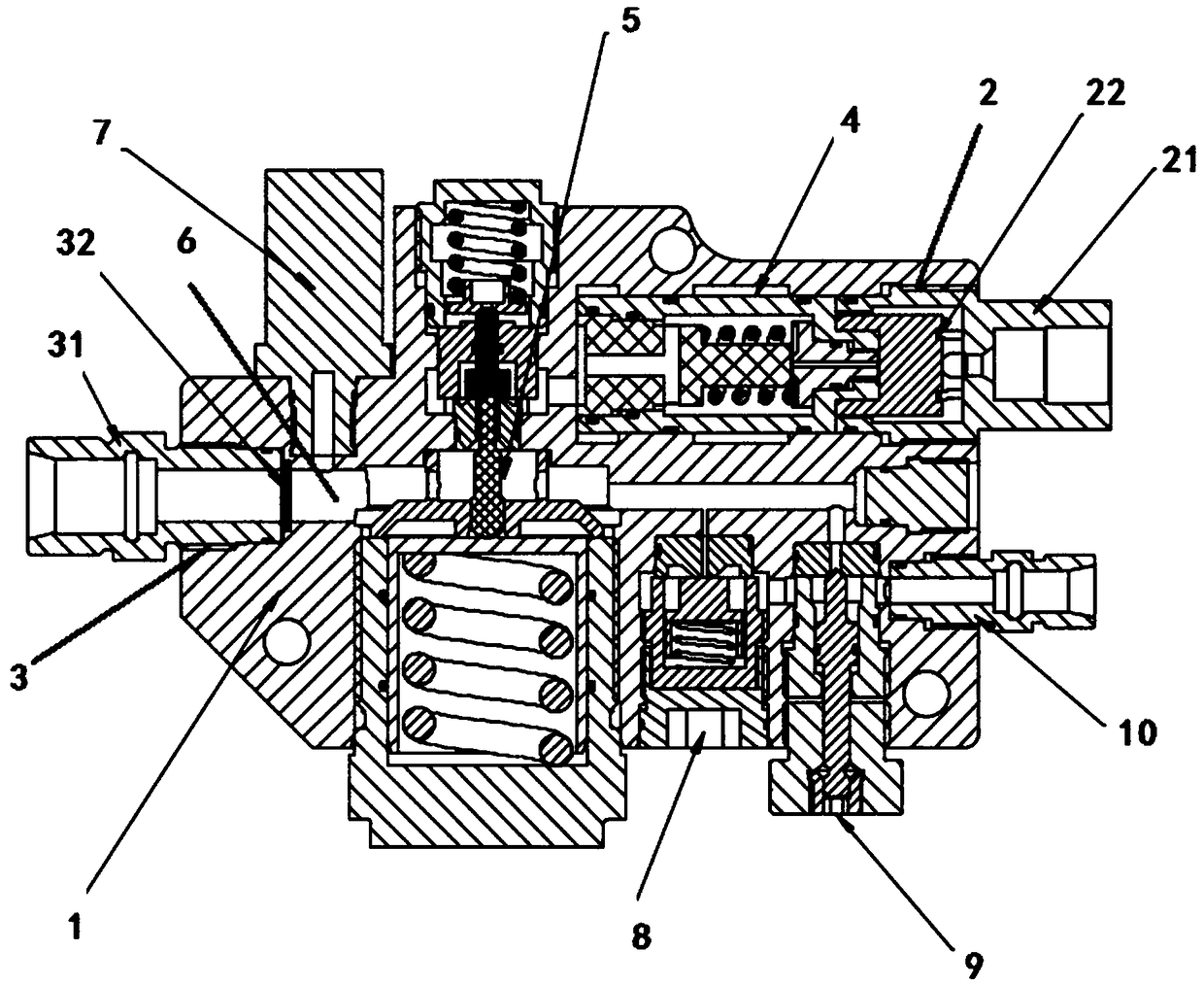

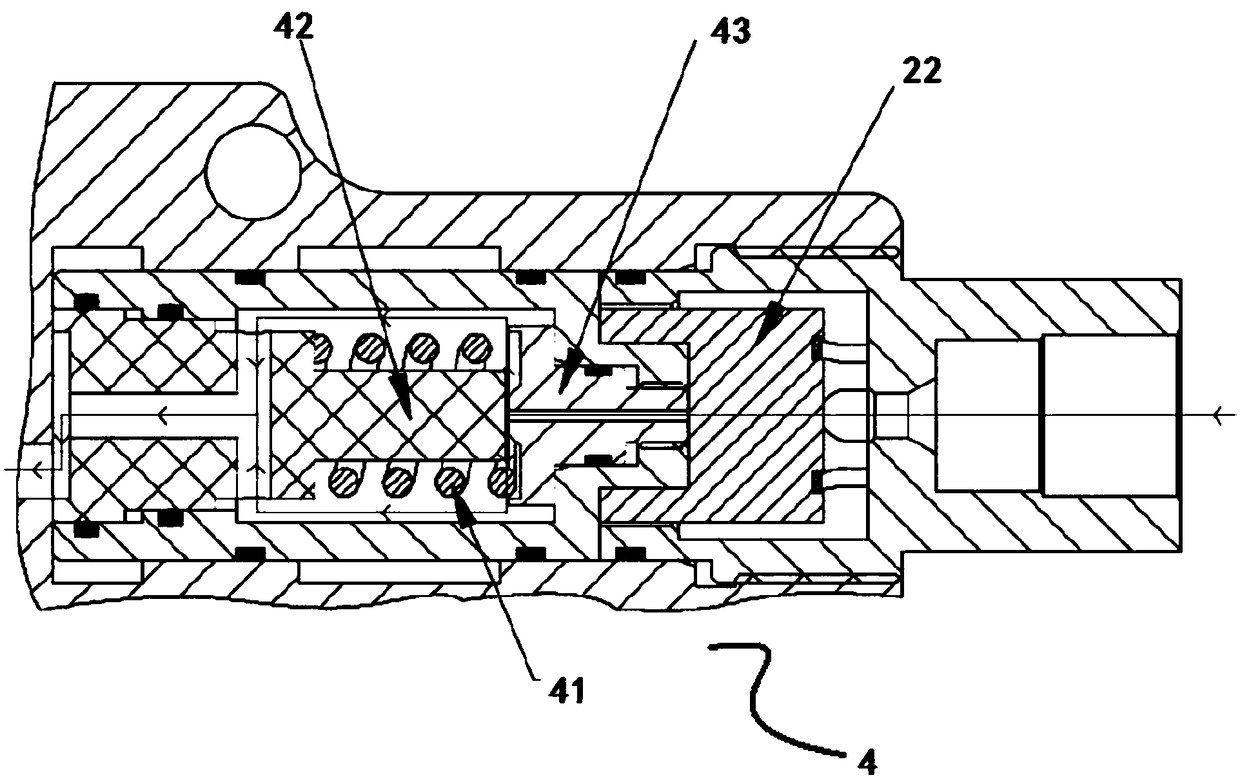

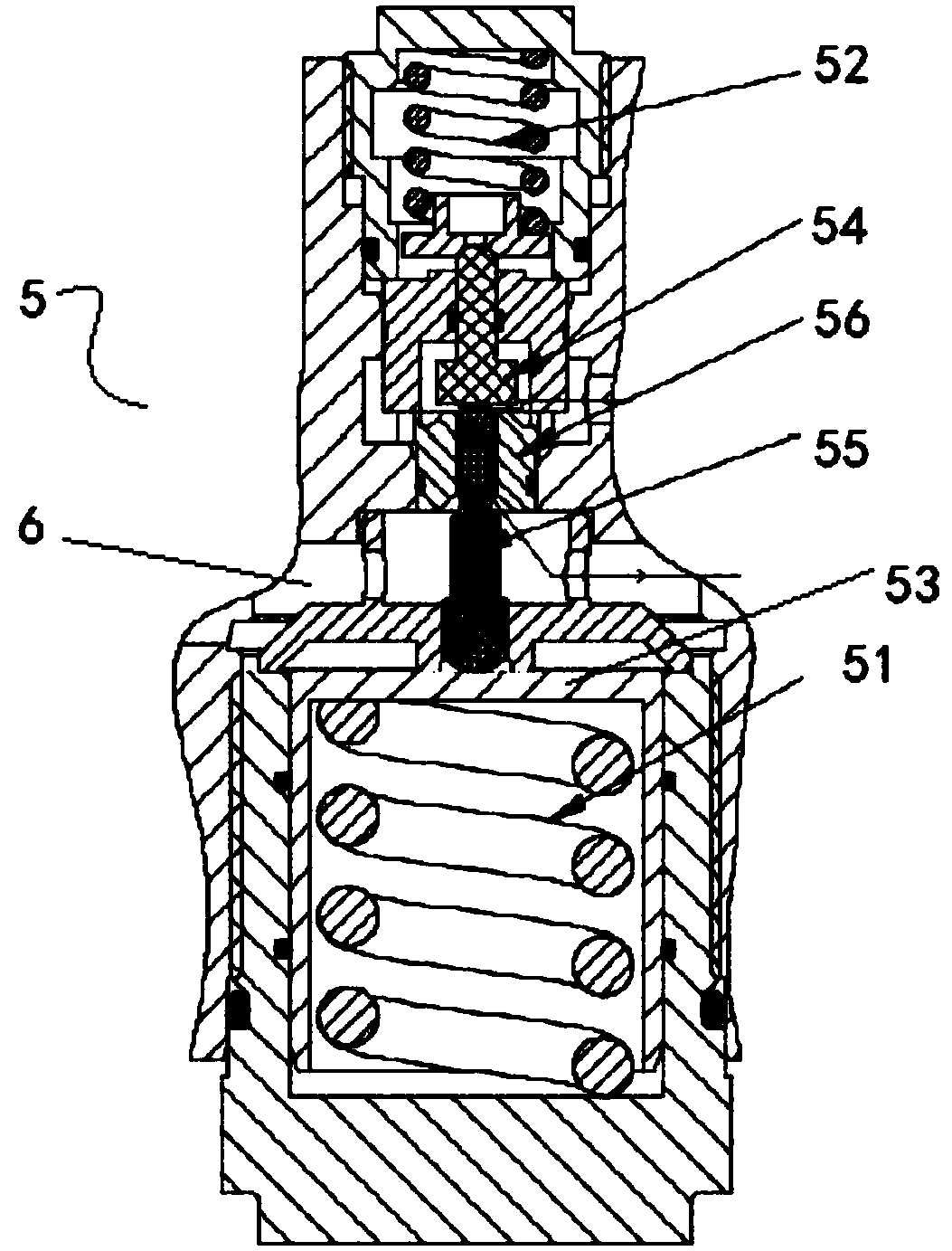

[0023] Such as Figures 1 to 3 As shown, the present invention provides an integrated pressure reducing valve, which includes: a valve body 1, an inlet 2 and an outlet 3 located outside the valve body 1, and a pressure reducing system located inside the valve body 1, wherein: the The inlet 2 is in fluid communication with the gas source outlet of the hydrogen fuel cell electric vehicle, and the outlet 3 is in fluid communication with the downstream stack of the hydrogen fuel cell electric vehicle; and the decompression system includes: located at the inlet 2 and the The first-stage pressure-relief valve 4 and the second-stage pressure-relief valve 5 connected between the outlets 3 and in fluid order, and the first-stage axis of the first-stage pressure-relief valve 4 and the second-stage pressure-relief valve The second level axes of 5 are arranged perpendicular to each other.

[0024] The decompression valve in the present invention has a two-stage decompression system to en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com