An automatic mold opening and closing mechanism

An opening and closing mechanism and automatic mold technology, applied in the field of automatic mold opening and closing mechanism, can solve the problems of high labor intensity, low work efficiency, and potential safety hazards, and achieve the effect of reducing labor intensity and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

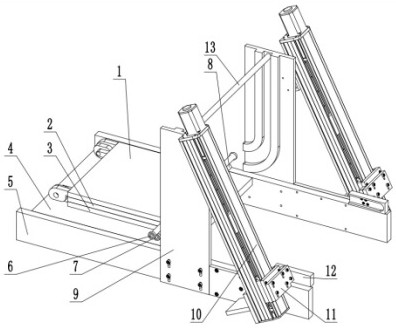

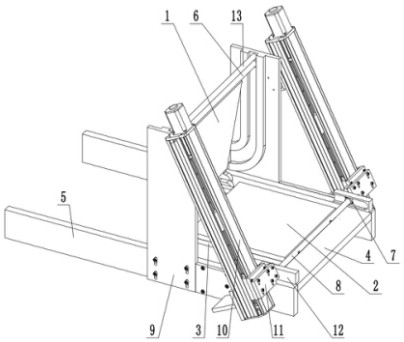

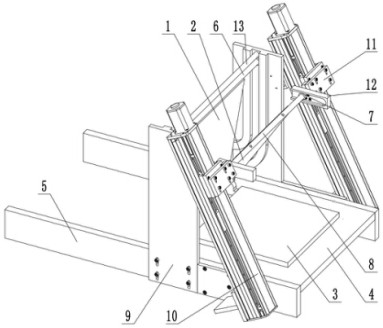

[0019] Combine below figure 1 , figure 2 with image 3 To explain this embodiment, the present invention relates to the field of automatic mold opening and closing, more specifically, an automatic mold opening and closing mechanism, including upper mold 1; middle mold 2; lower mold 3; bottom plate 4; side plate 5 ; Upper mold support shaft 6; bearing 7; middle mold support shaft 8; side slide plate 9; linear module 10; push-out part holder 11; push-out part 12; side slide plate support shaft 13, which can realize the automatic mold Opening and closing.

[0020] The lower mold 3 is connected to the bottom plate 4, the connection between the bottom mold 3 and the bottom plate 4 is welding, and the lower mold 3 is located at the upper end of the bottom plate 4, the middle mold 2 is connected with the lower mold 3, and the middle mold 2 and the lower mold 3 are connected The method is rotary connection, and the middle mold 2 is located at the upper end of the lower mold 3, the uppe...

specific Embodiment approach 2

[0022] Combine below figure 1 , figure 2 with image 3 This embodiment will be described. This embodiment will further describe the first embodiment. The side plate 5 is fixed.

specific Embodiment approach 3

[0024] Combine below figure 1 , figure 2 with image 3 This embodiment will be described. This embodiment will further explain the first embodiment. The number of the side plates 5 is two, the number of the side slide plate 9 is two, and the number of the linear modules 10 is two. There are two, the number of the push-out component fixing seat 11 is two, and the number of the push-out component 12 is two.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com