Double bridge mud guard intermediate support assembly

An intermediate bracket and fender technology, which is applied in the field of auto parts, can solve the problems of heavy weight and poor reliability of the fender bracket assembly, and achieve the effects of taking into account reliability and rigidity requirements, reducing weight and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

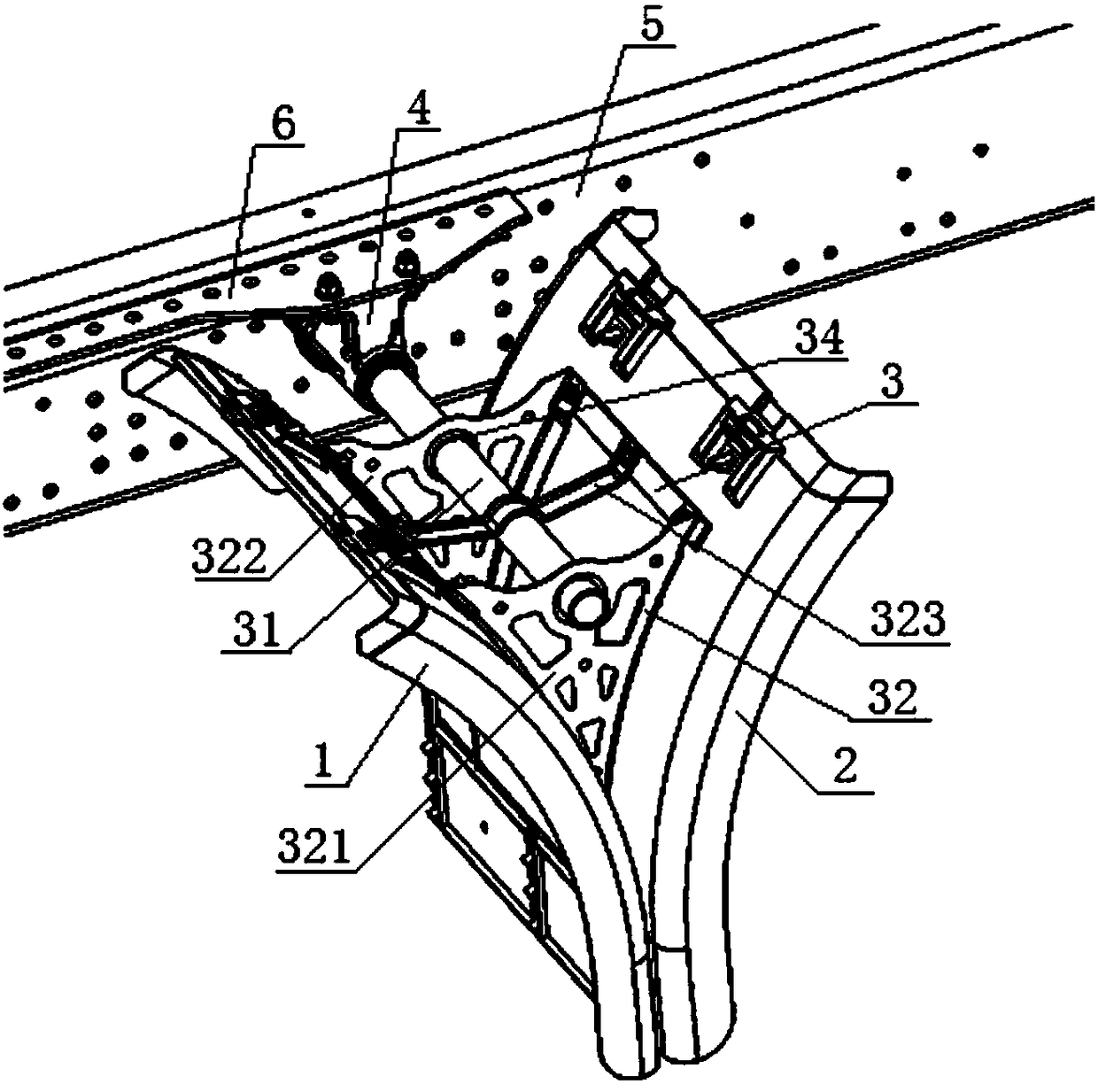

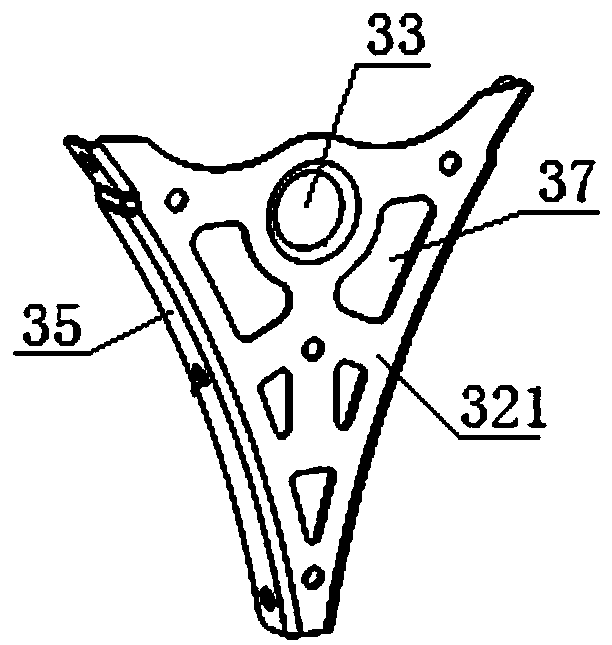

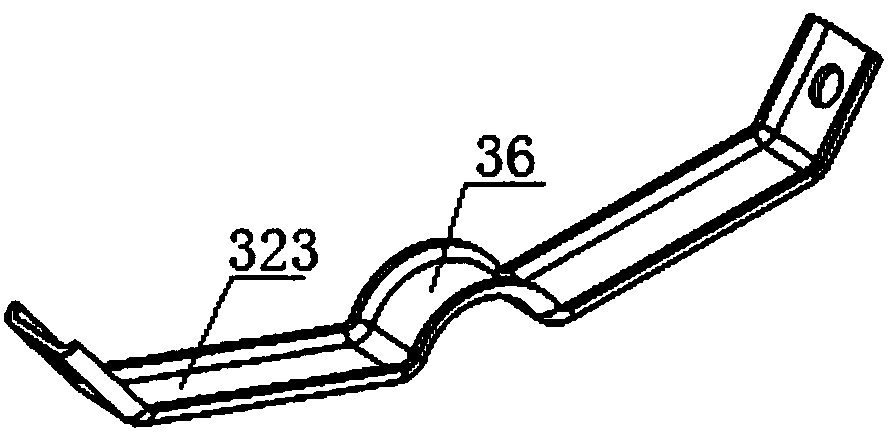

[0034] see Figure 1 to Figure 4, a double-bridge fender intermediate bracket assembly, including a No. 1 fender 1, a No. 2 fender 2, an intermediate bracket assembly 3, and a fender support 4, and the intermediate bracket assembly 3 includes a support Pipe 31, connecting bracket 32, intermediate bracket 323 between No. 1 connecting bracket 321 and No. 2 connecting bracket 322. Said connecting bracket 32 includes No. 1 connecting bracket 321 and No. 2 connecting bracket 322 which are uniform in structure and arranged symmetrically. The No. 1 connecting bracket 321 and the No. 2 connecting bracket 322 are all triangular structures, and the No. 1 connecting bracket 321 and the No. Tube connection through hole 34, one end of the support tube 31 passes through the No. 1 support tube connection through hole 33 and the No. 2 support tube connection through hole 34 in sequence, and then inserts into the inner cavity of the fender support 4 and vulcanizes with it. , the two sides o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com