Cable fast winding device with automatic wire outlet function

A winding device and cable technology, which is applied in the field of winding devices, can solve problems such as cable damage, shortened cable service life, and difficult layout, and achieve the effects of prolonging service life, speeding up winding speed, and eliminating high failure rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

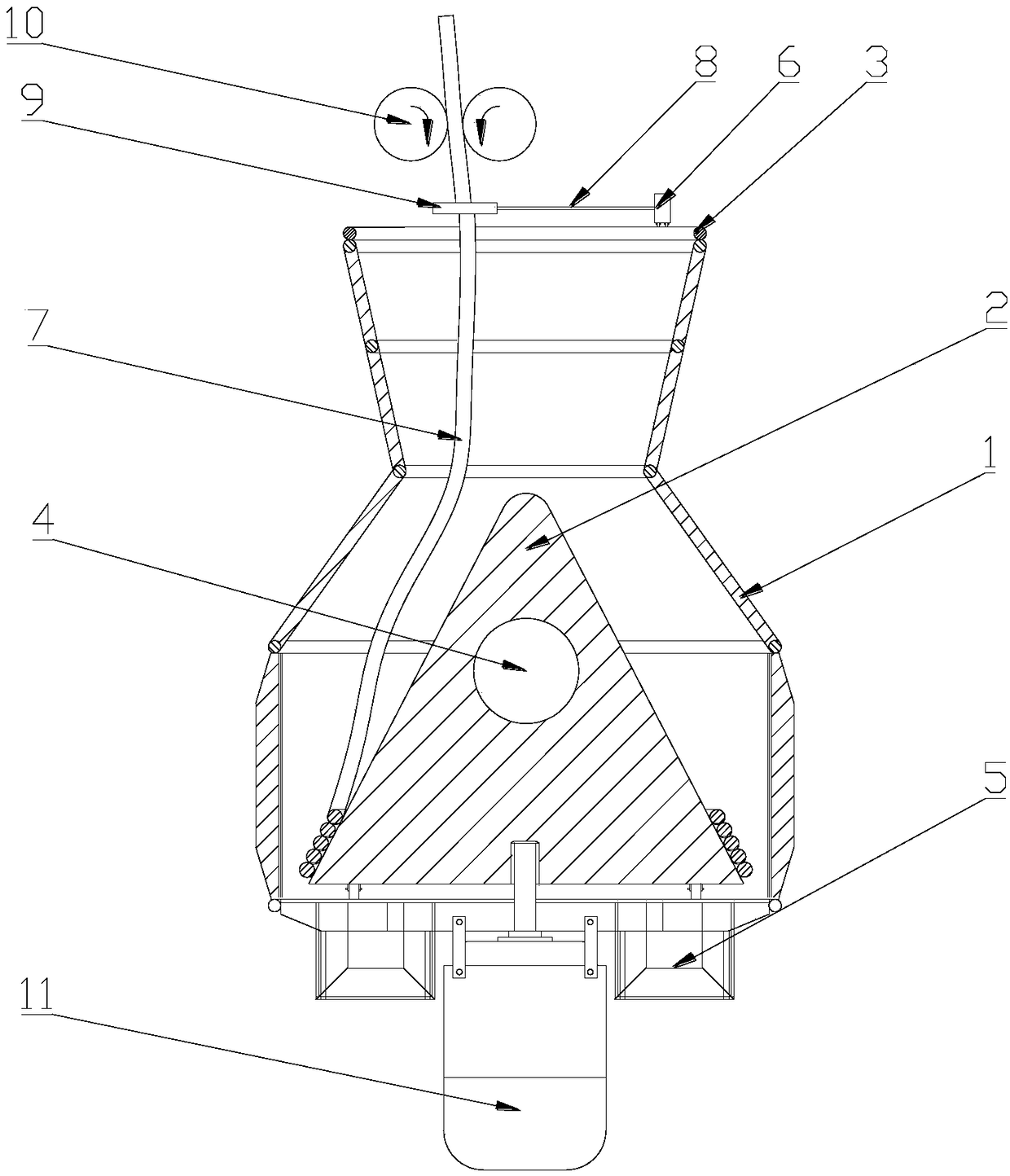

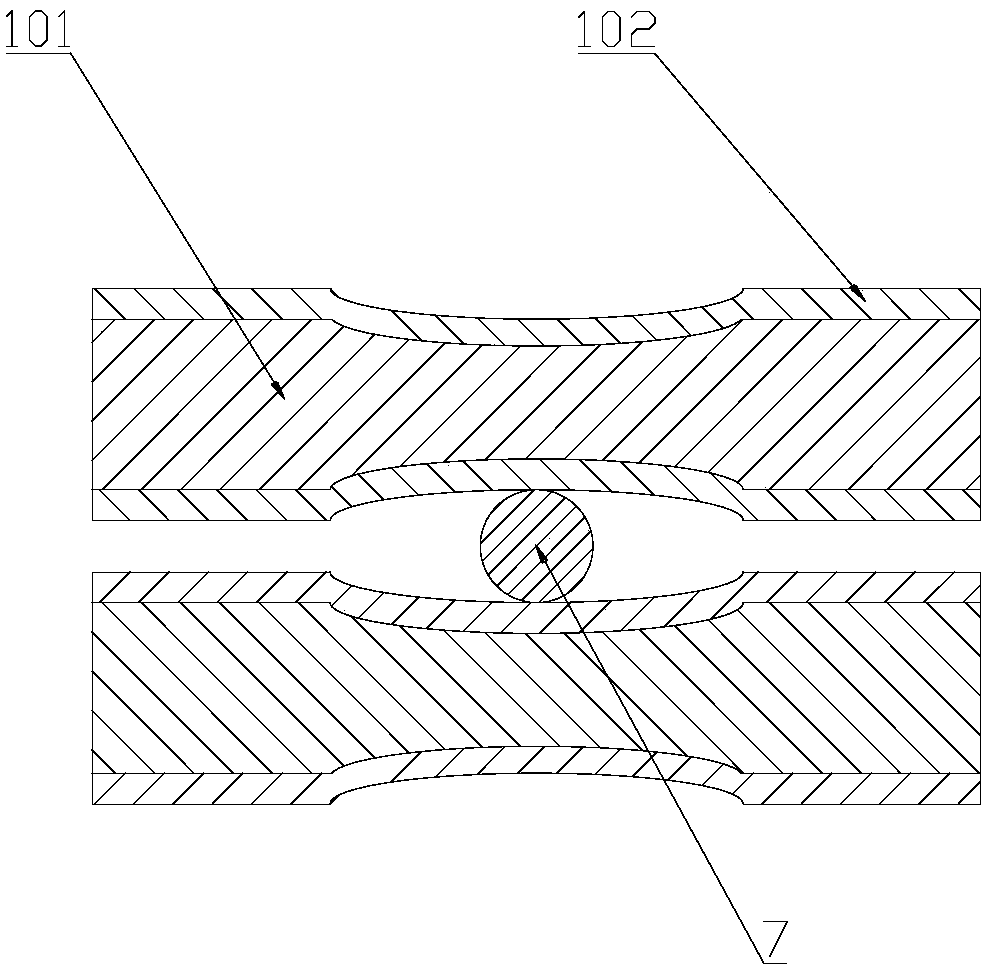

[0019] Such as figure 1 and figure 2 As shown, a fast winding device for cables that can be automatically discharged includes a cable holding frame 1, an automatic wire discharging mechanism 10 is provided above the cable containing frame 1, and a winding mechanism is provided inside the cable containing frame 1. The automatic wire outlet mechanism 10 includes two wire outlet rollers 101 that are horizontally opposite to each other. The outlet rollers 101 are in the shape of waist drums. The material of the cushion 102 is foam or silica gel, and the winding mechanism includes a conical winding column 2, the cone top of the winding column 2 faces upwards, and the lower surface of the bottom of the cable holding frame 1 is provided with a drive Motor 11, the output end of the driving motor 11 extends upwards into the cable holding frame 1 and is spline...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com