Pneumatic stop valve

A pneumatic shut-off valve and cylinder-driven technology, which is applied in the direction of valve lift, valve details, valve device, etc., can solve the problems of difficult valve head replacement and repair, and achieve the effect of expanding the scope of use and improving practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The application will be described in further detail below in conjunction with the accompanying drawings.

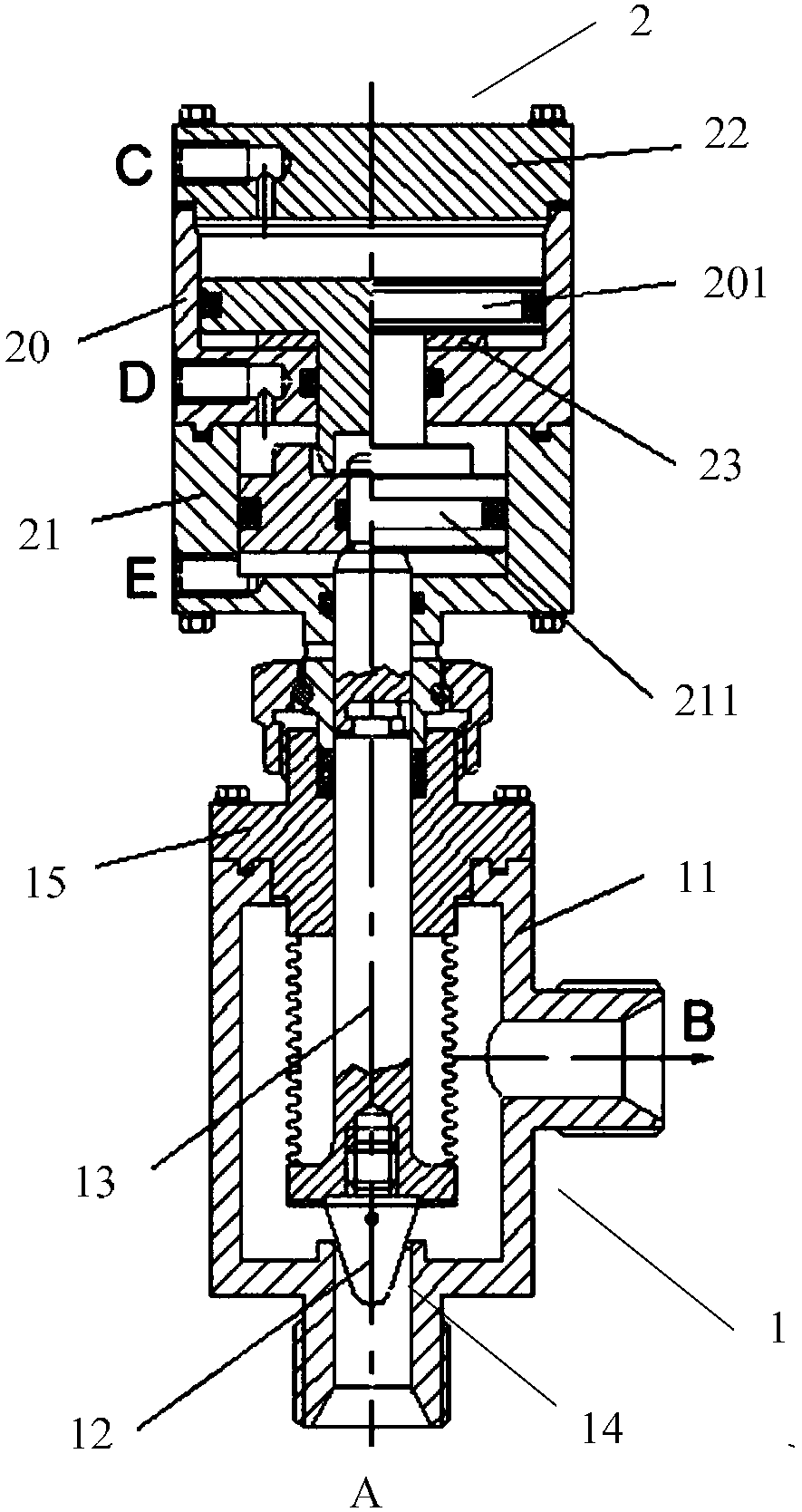

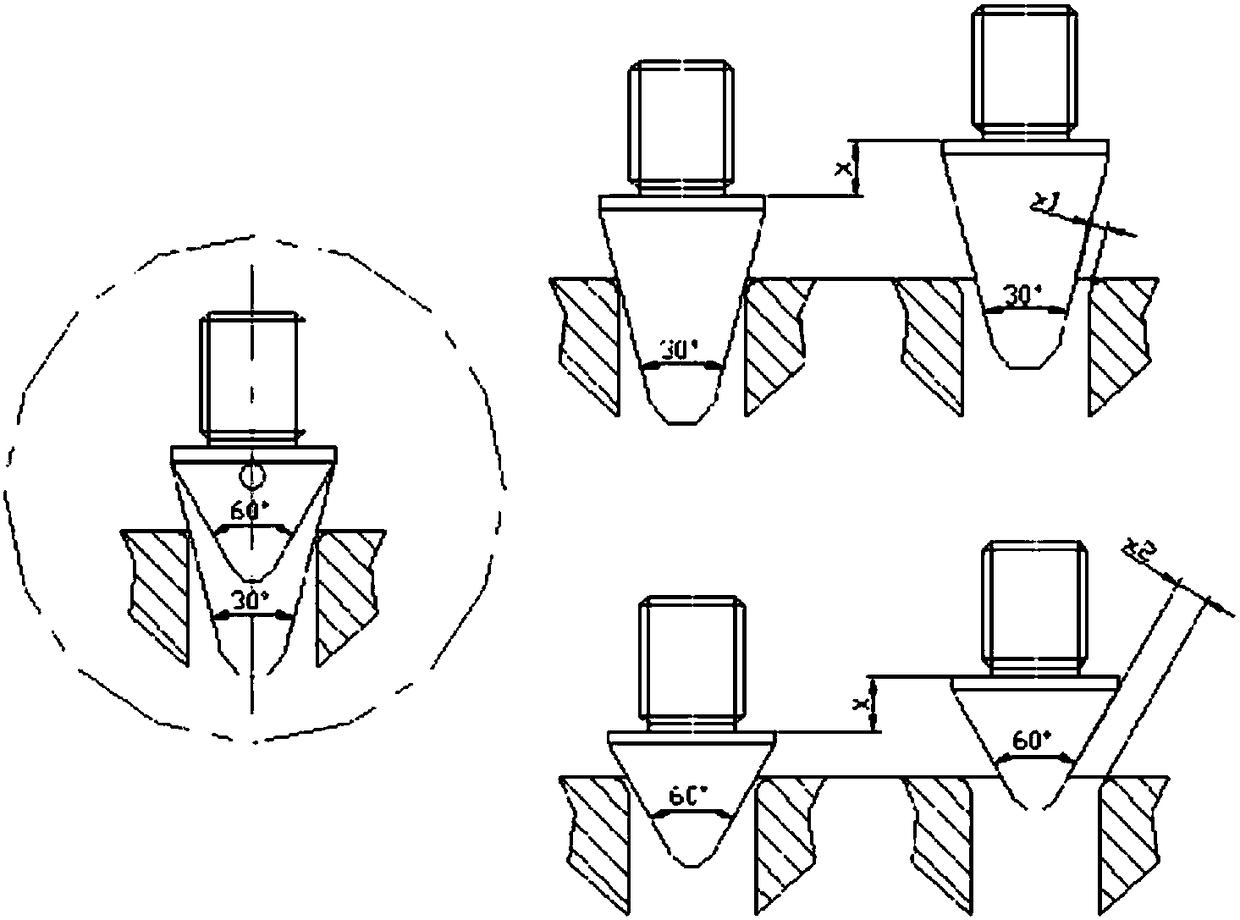

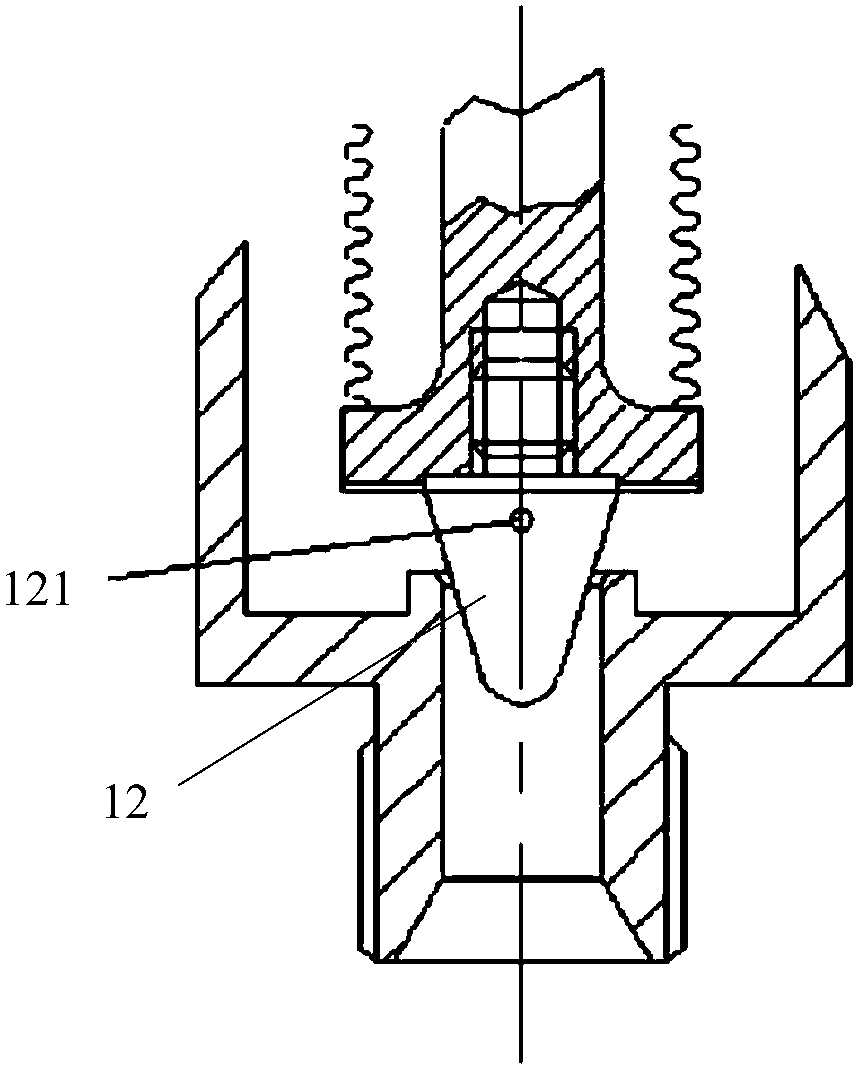

[0023] figure 1 A schematic diagram of the structure of the pneumatic shut-off valve in an embodiment of the present application is shown. The pneumatic shut-off valve includes: a valve body device 1 and a cylinder drive device 2, wherein the cylinder drive device 2 includes a cylinder upper chamber 20 and a cylinder lower chamber 21 , an upper piston 201 and a lower piston 211; the valve body device 1 includes a valve body 11, a valve head 12, a valve core 13 and a valve seat sealing surface 14; an upper piston 201 is arranged in the upper cavity 20 of the cylinder, and the cylinder The lower chamber 21 is provided with a lower piston 211, and the combined force of the upper piston 201 and the lower piston 211 is used to drive the valve body device 1 into the corresponding working mode of the valve; the inner cavity of the valve body 11 is provided with Vertical ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap