Spatial correlation-based infrared thermal image processing method

A spatial correlation and image processing technology, applied in the field of infrared thermal image processing based on spatial correlation, can solve the problem of low detection efficiency, failure to consider the simultaneous existence and mutual influence of multiple defects, lack of research on multi-defect detection, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

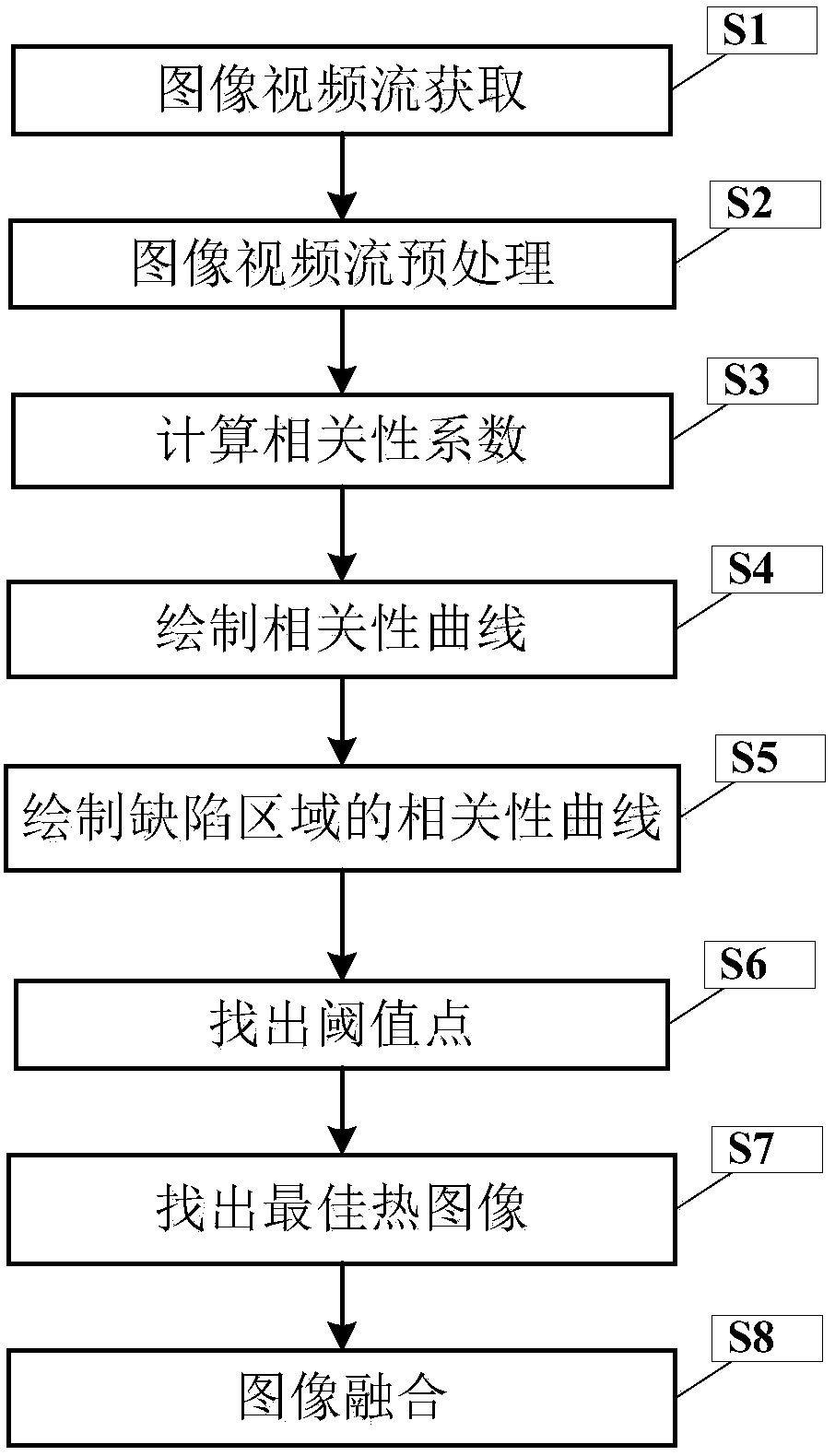

[0034] figure 1 It is a flow chart of the infrared thermal image processing method based on the spatial correlation of the present invention.

[0035] In this example, if figure 1 Shown, the present invention a kind of infrared thermal image processing method based on spatial correlation, comprises the following steps:

[0036] S1. Heat the stainless steel specimen at or below room temperature for a period of time, and then collect the video stream data of the heating stage online in real time, without cooling data. In this embodiment, some preprocessing, such as denoising processing, may be performed on the collected video stream, so as to eliminate the time difference caused by the instrument and the interference of external noise.

[0037] Such as figure 2 As shown, the tested piece is made of stainless steel, and there are holes and groove defects. The No. 3 and No. 4 defects in the test piece were heated by pulsed eddy current, and part of the infrared thermal image ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com