Zigzagging carbon-free vehicle based on magnetic steering mechanism

A steering mechanism, carbon-free car technology, applied in toy cars, toy transmission, toys and other directions, can solve the problems of increasing assembly difficulty, insufficient torque, energy consumption, etc., to increase the passability of the rod, reduce energy consumption, reduce The effect of uncertainty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

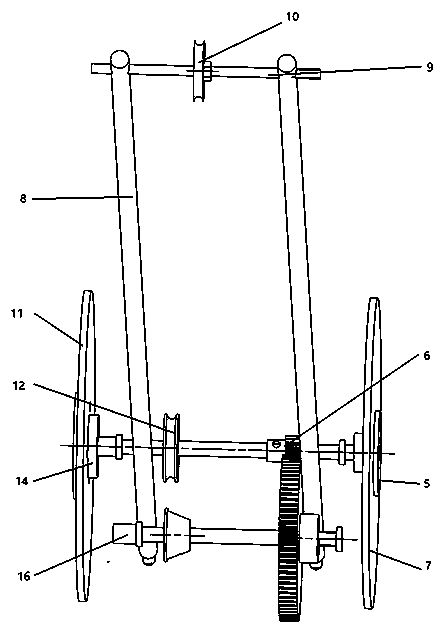

[0018] see figure 1 As shown, the S-type magnetic steering carbon-free trolley includes a frame, a driving device, a transmission device and a magnetic steering device.

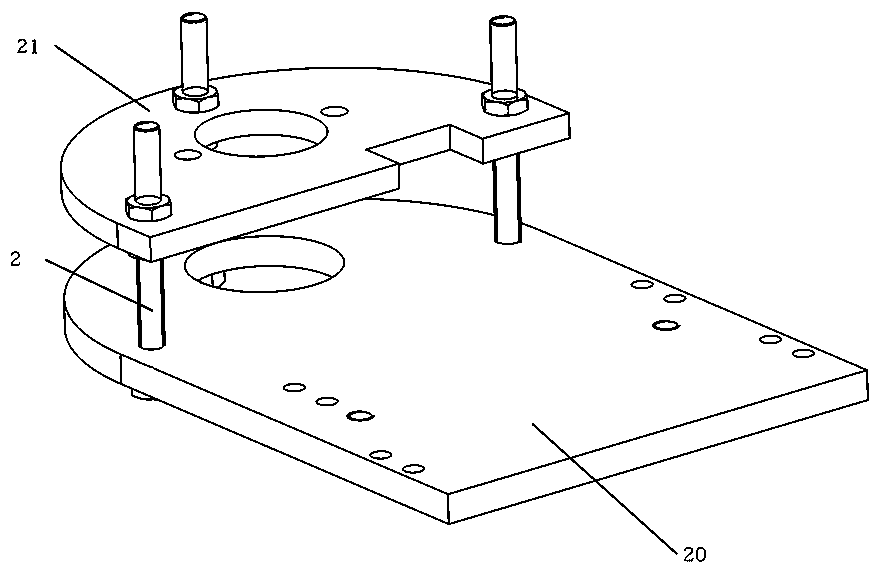

[0019] see figure 1 , figure 2 As shown, the structure of the vehicle frame is tower-shaped, and the vehicle frame includes a lower base plate 20, an upper base plate 21, an adjusting bolt 2, a vertical bearing seat 3, a horizontal bearing seat 1, and a weight suspension rod 8. The weight suspension rod 8 is installed on the middle part of the lower base plate 20 through threaded connection, the upper base plate 21 is installed on the front end of the lower base plate through three sets of adjusting bolts 2, the horizontal bearing seat 1 is fixed on the upper base plate 21 by two bolts, and the two sides of the middle part of the lower base plate 20 Vertical bearing block 3 is installed with screw connection mode with rear both sides.

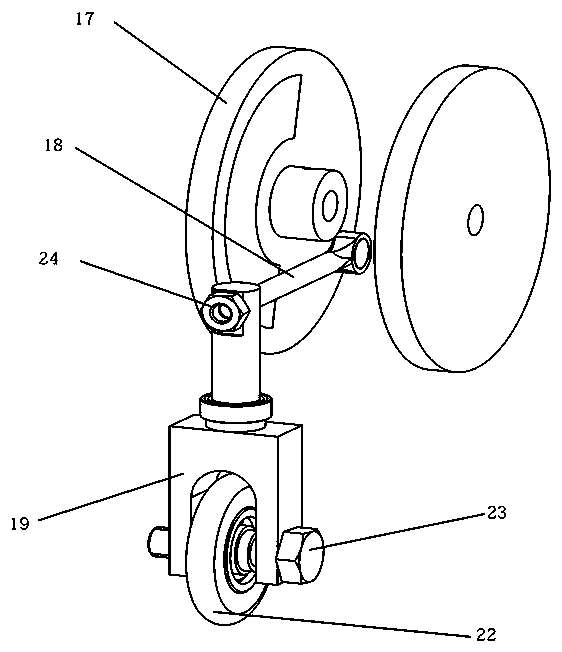

[0020] see figure 1 , image 3 As shown, the drive device includes:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com