Washing desalination system and method for waste incineration fly ash or kiln dust

A technology of waste incineration fly ash and elution system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

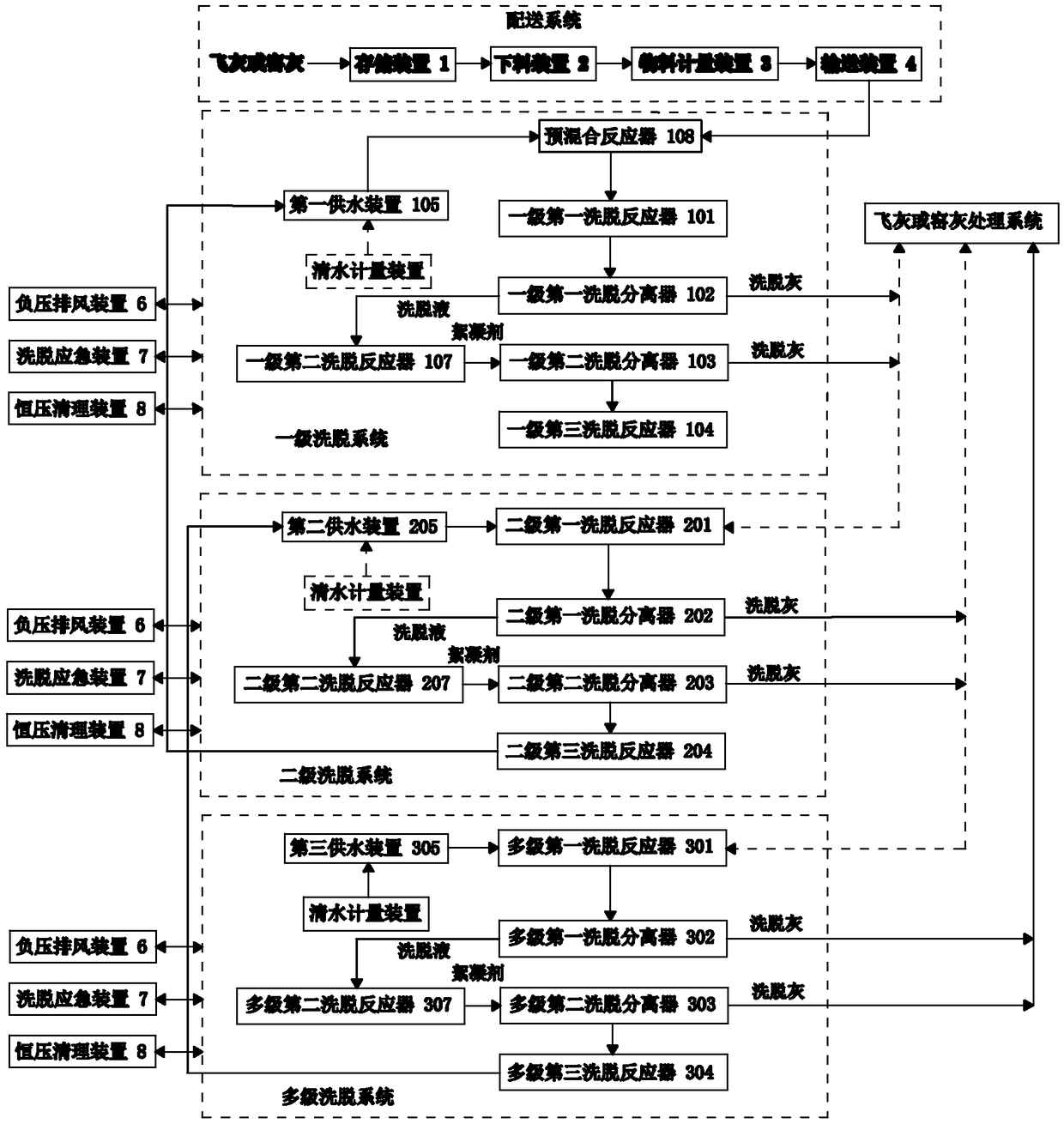

Image

Examples

Embodiment Construction

[0056] The invention includes a multi-level elution system, and performs elution treatment for fly ash or kiln dust to be treated with a chlorine salt content greater than or equal to 4%, wherein the chlorine content is greater than or equal to 2%. According to the different chlorine salt content and chlorine content in the fly ash or kiln dust to be treated, different levels of elution systems can be used for combined treatment to ensure that the chlorine salt content in the eluted ash discharged to the outside is less than or equal to 2%, and the chlorine content is less than 2%. Equal to 1%. When the chlorine salt content in fly ash or kiln dust to be treated is greater than or equal to 4% and less than 10%, and when the chlorine content is greater than or equal to 2% and less than 5%, it only needs to be eluted through the primary elution system; when the fly ash to be treated Or when the chlorine salt content in the kiln dust is greater than or equal to 10% and less than ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap