Heat pump air conditioner turbulence tube-shell dry-type evaporator

A technology of heat pump air conditioner and spoiler tube, applied in the direction of heat exchanger type, heat exchanger shell, indirect heat exchanger, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

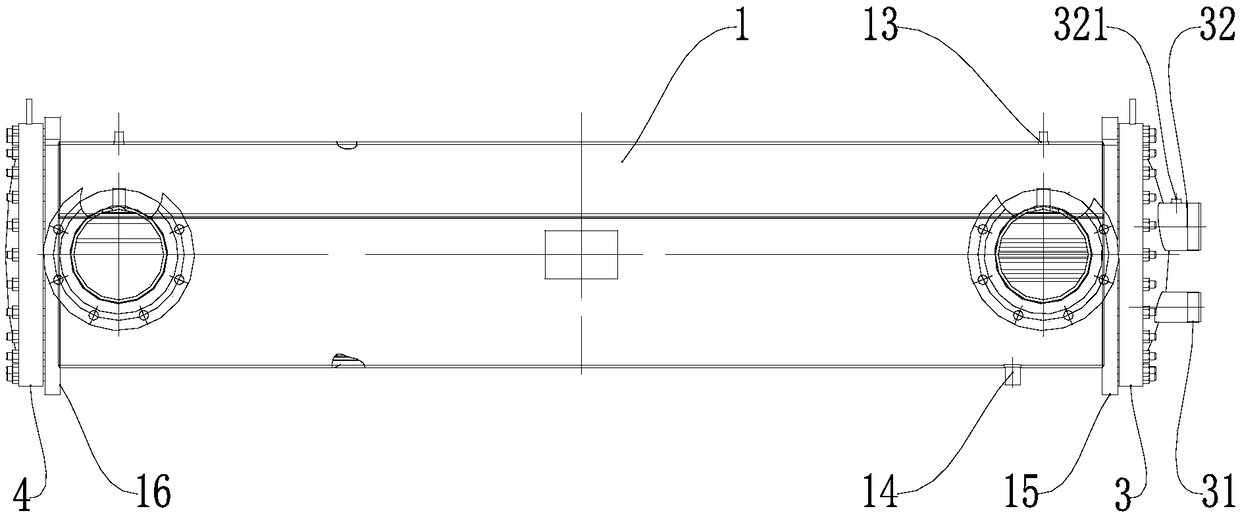

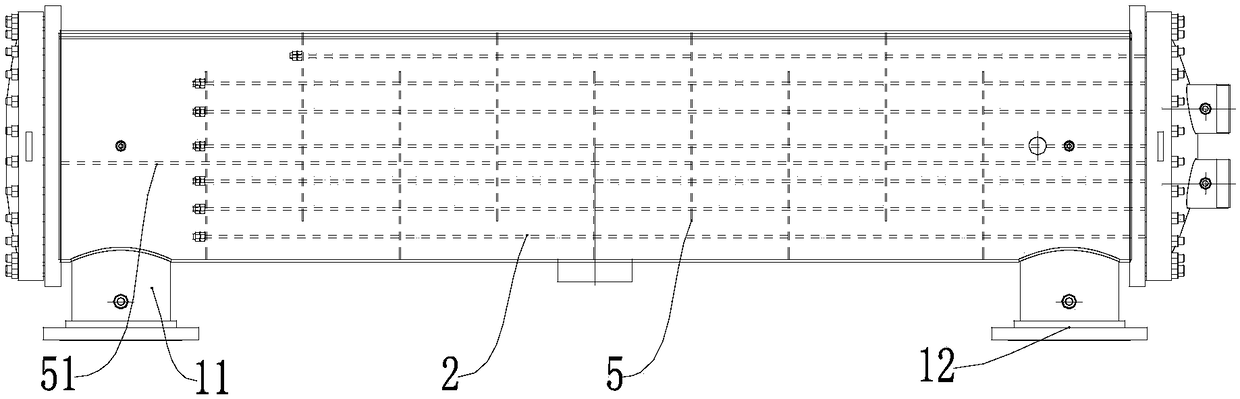

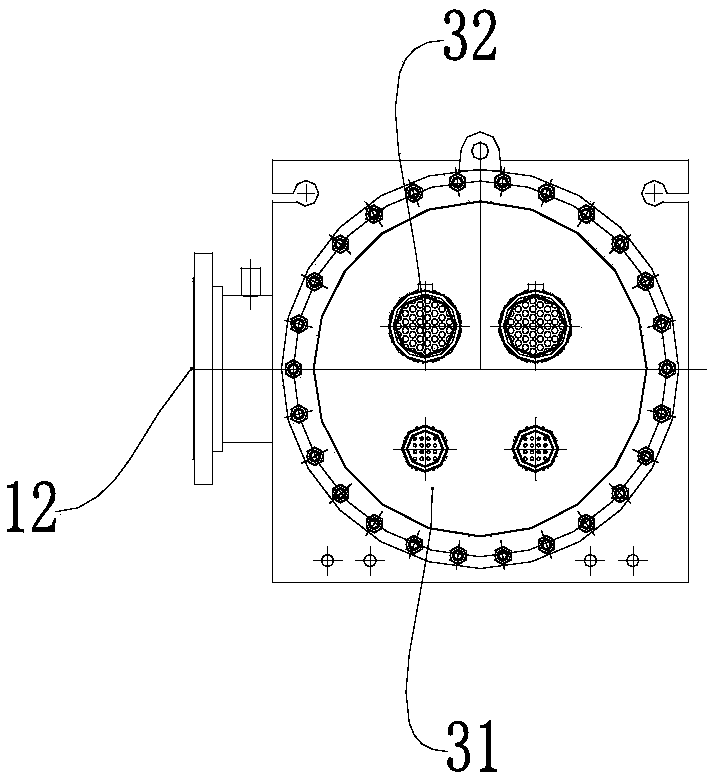

[0014] Heat pump air conditioner spoiler tube shell dry heat exchanger, including shell 1, copper tube 2, front end cover 3, rear end cover 4 and spoiler 5; the two ends of the shell 1 are respectively welded with a front bottom plate 15 and a rear bottom plate 16. The front bottom plate 15 is a circular plate, which is welded to the front end of the shell 1, and has holes; the rear bottom plate 16 is a circular plate, which is welded to the rear end of the shell 1; The shell 1 is a relatively thin shell, and the front and rear parts cannot be installed in the form of bolts or flanges. Therefore, after the front bottom plate 15 and the rear bottom plate 16 are welded and installed, the front bottom plate 15 and the rear bottom plate 16 can be opened. Bolt holes or flange holes for easy installation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap