A quantitative prediction method for field investigation of flue-cured tobacco maturity for determining the optimum harvest time of tobacco leaves

A forecasting method and harvesting period technology, applied in measuring devices, testing plants/trees, instruments, etc., can solve the problems of difficult to implement the mature and harvesting of flue-cured tobacco, and achieve long-term difficult to implement, good results, and easy to master. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

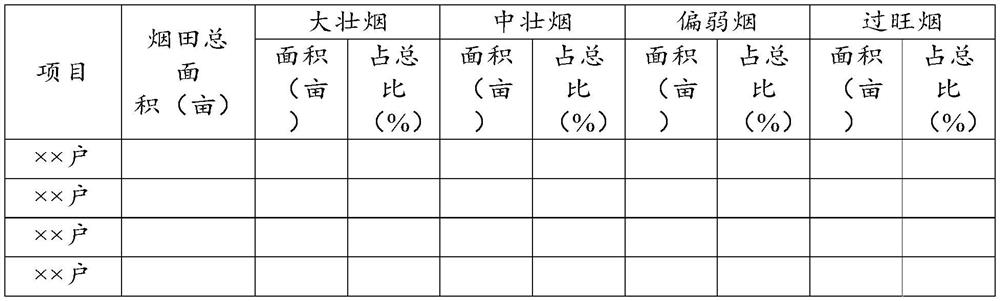

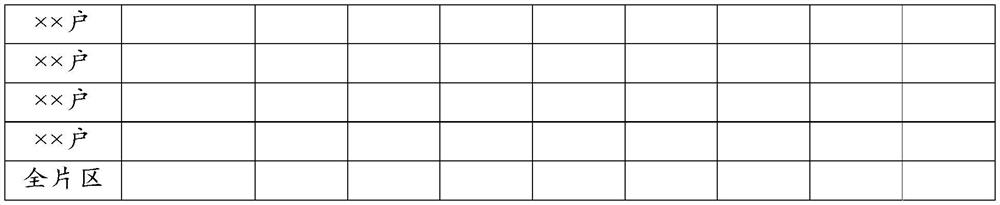

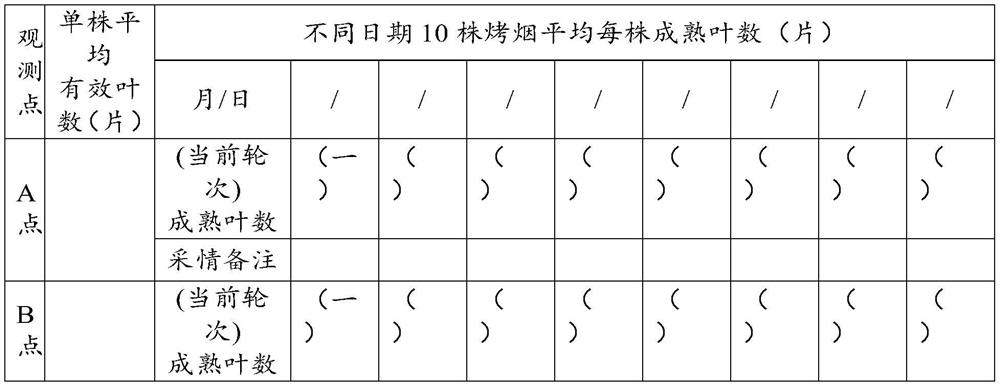

[0051] Taking the barn group as the unit, all the tobacco fields in the curing area covered by the barn group were divided into four types of tobacco fields: "big strong tobacco", "medium strong tobacco", "weak tobacco" and "excessive tobacco" Category, count and fill in the area of each tobacco field category, the area of the above four categories of tobacco fields is 15 mu, and the planting amount per mu is 1100 plants; divide 2 representative monitoring fields in each tobacco field category Each representative monitoring field has an area of 1 mu and is marked on each representative monitoring field; one representative sampling point is selected in each representative monitoring field, and each representative sampling point 10 tobacco plants were selected as investigation tobacco plants, and these 10 survey tobacco plants were 10 continuous tobacco plants growing in the same planting row, and the tops of the first and tenth tobacco plants were marked.

[0052] Before ...

Embodiment 2

[0061]Divide the tobacco fields into three types of tobacco fields: "big strong tobacco", "medium strong tobacco" and "excessive tobacco", count and fill in the area of each type of tobacco field, the area of the above three types of tobacco fields is 20 mu, the planting amount per unit area is 1,000 plants; each category of tobacco field is divided into 1 representative monitoring field, and the area of each representative monitoring field is 1 mu and marked on the representative monitoring field ; Select 2 representative sampling points in each representative monitoring field, and select 8 tobacco plants in each representative sampling point as investigation tobacco plants, and these 8 investigation tobacco plants are continuous plants grown in the same planting row. 8 tobacco plants, mark the tops of the first and eighth tobacco plants.

[0062] Before the first round of tobacco leaf curing (early May), the field investigation of tobacco leaf maturity was carried out ...

Embodiment 3

[0070] Divide the tobacco fields into two categories of "big strong tobacco" and "medium strong tobacco", count and fill in the area of each type of tobacco field. The area of the above two types of tobacco fields is 13 mu, and the planting amount per mu Both are 1200 plants; divide 2 representative monitoring fields in each tobacco field category and mark each representative monitoring field, determine and fill in the area of each representative monitoring field (each representative The area of the permanent monitoring field is 1 mu); select 2 representative sampling points in each representative monitoring field, and select 12 tobacco plants in each representative sampling point as the survey tobacco plants, and the 12 survey tobacco plants The tobacco plants are 12 consecutive plants grown in the same planting row, and the tops of the first and twelfth plants are marked.

[0071] From the first round of tobacco leaf curing (May 5th), field surveys of tobacco leaf ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com