Bottom chain piece assembly device for chain molding assembly die

An assembly device and chain piece technology, applied in the direction of metal chains, etc., can solve problems such as low manual operation efficiency, prone to defective products, and insufficient product quality control, so as to improve yield and efficiency, fast assembly, positioning and progress Precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

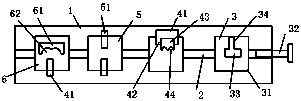

[0011] Combine below figure 1 Specific examples:

[0012] The chain forming and assembling mold includes a bottom plate 1, characterized in that the bottom plate 1 is provided with an assembly groove 2, and the bottom plate 1 is provided with a bottom chain assembly area 3, a shaft sleeve assembly area 4, and a pin assembly area 5 and the top chain assembly area 6; the bottom chain assembly area 3 includes a feed plate 31 and a pushing device 32, the feed plate 31 is provided with a feed port 33, the feed port 33 communicates with the assembly groove 2 , The bottom chain piece enters the assembly groove through the feed plate and is pushed along the assembly groove by the pushing device to the shaft sleeve fitting area. The shaft sleeve fitting area 4 includes a shaft sleeve positioning device 41, and the shaft sleeve is assembled on the bottom chain piece by the shaft sleeve positioning device After entering the pin assembly area 5, the pin assembly area includes a pin position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com