Arraying device of pin sleeves

A technology for aligning devices and pin sleeves, which is applied in the field of aligning devices, and can solve problems such as the inability to guarantee the directionality of pin sleeves and affecting assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

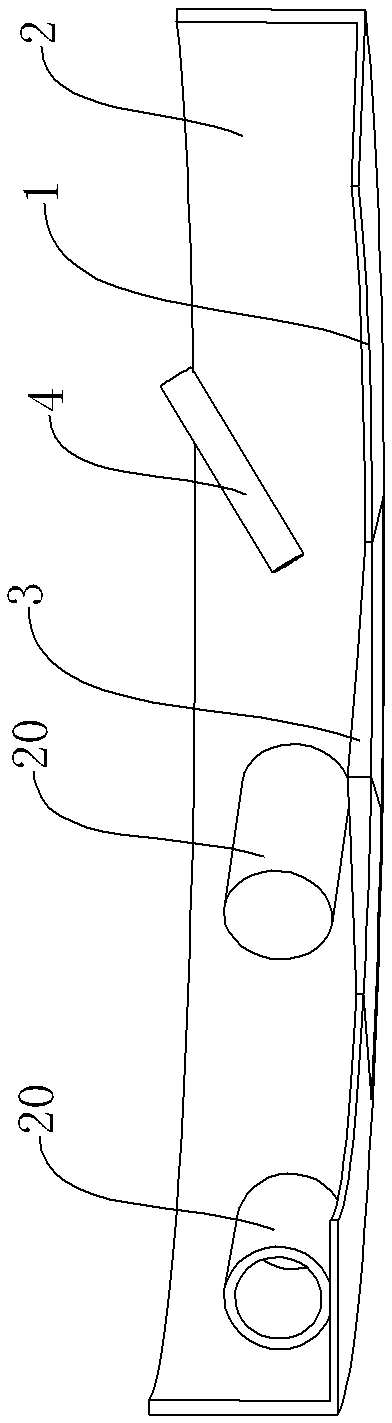

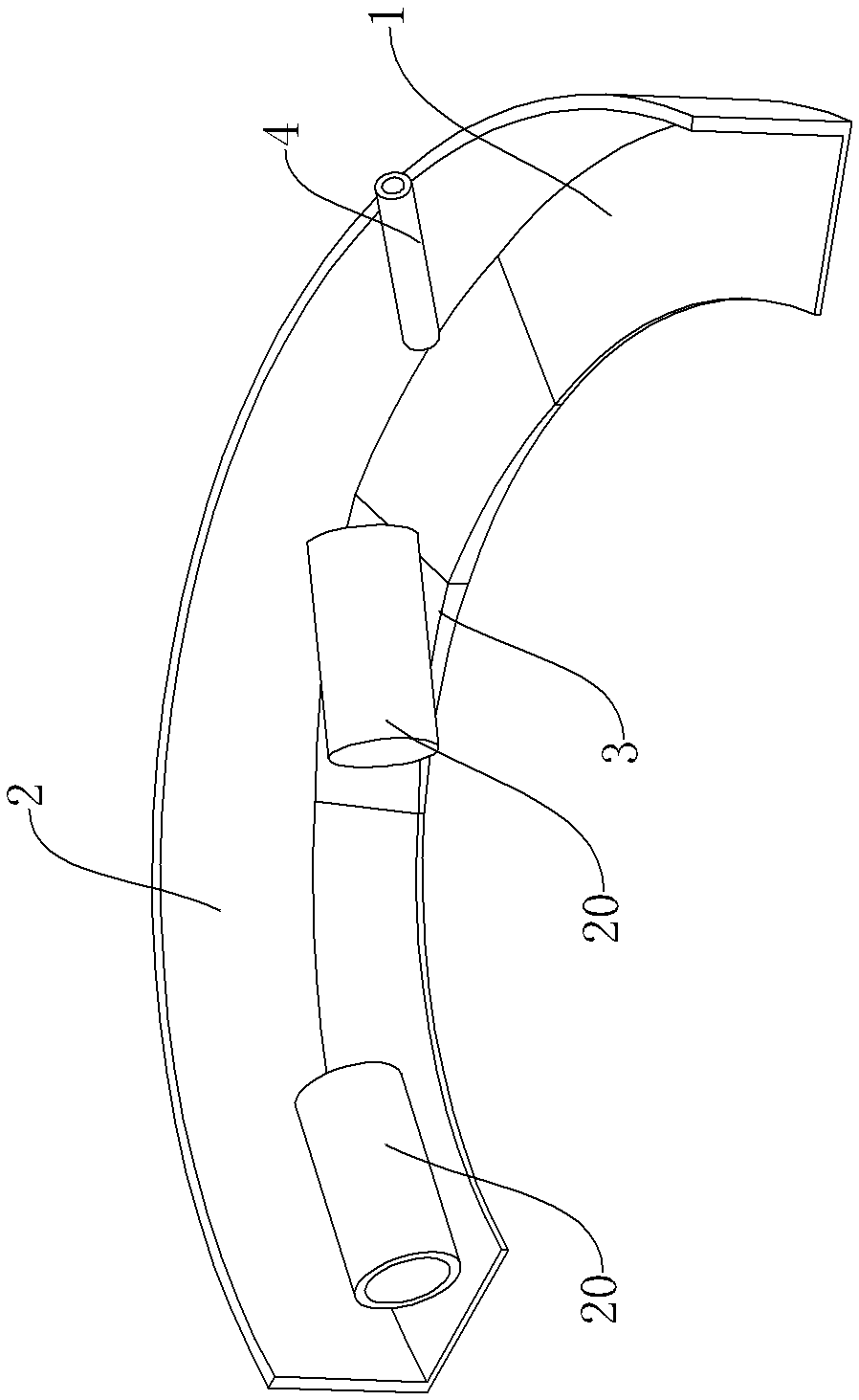

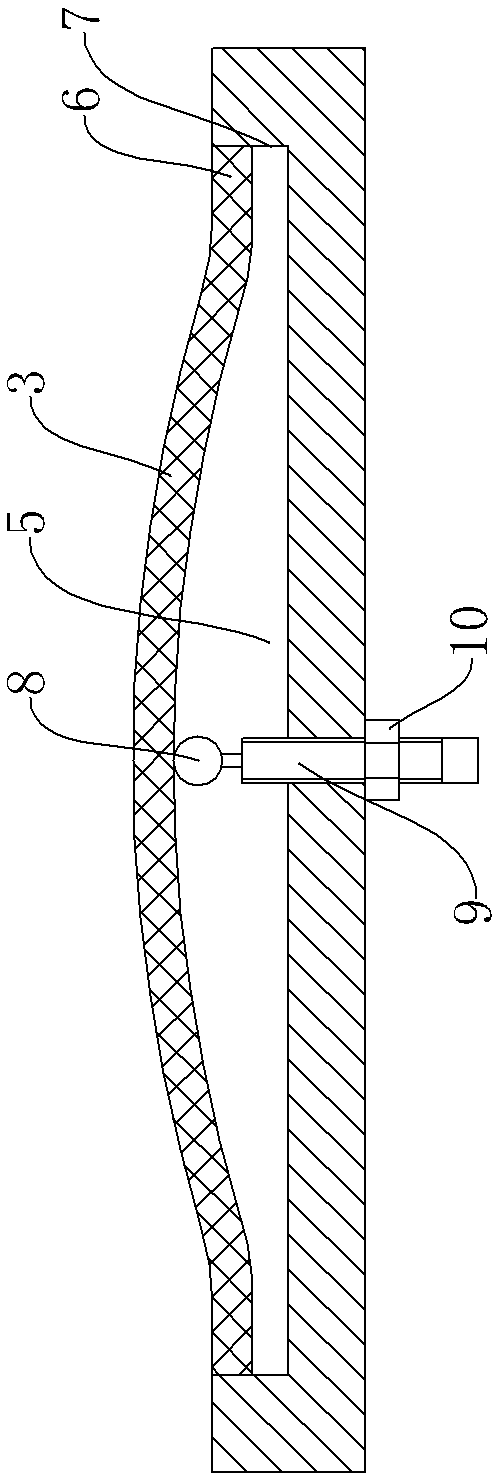

[0012] Such as figure 1 As shown, an alignment device of pin sleeves, the pin sleeve is a hollow structure and one end is encapsulated by the bottom plate, the alignment device includes a slide plate 1, a guide plate 2, a nozzle 4, an air source and a drive unit, the slide plate 1 is arranged horizontally, and the side of the slide plate 1 The arc-shaped guide plate 2 is fixed on the upper part, and the slope plate 3 forming an up and down slope structure is arranged in the middle part. The nozzle 4 is fixed on the top of the slide plate 1 and set towards the downhill direction of the slope plate 3. The nozzle 4 is connected to the air source through a pipeline, and the drive unit It is used to provide the initial velocity of the pin sleeve.

[0013] When the pin sleeve is about to go downhill, the air resistance received by the end of the package through the bottom plate and the end of the opening are different. When the end of the opening faces the nozzle, the air resistance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com