Ejection mechanism of plastic mold

A technology of ejection mechanism and plastic mold, which is applied in the field of plastic processing molds, can solve the problems of fatigue failure of return spring, high mold manufacturing cost, easy failure, etc., and achieve the effect of reliable reset action, less component parts and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

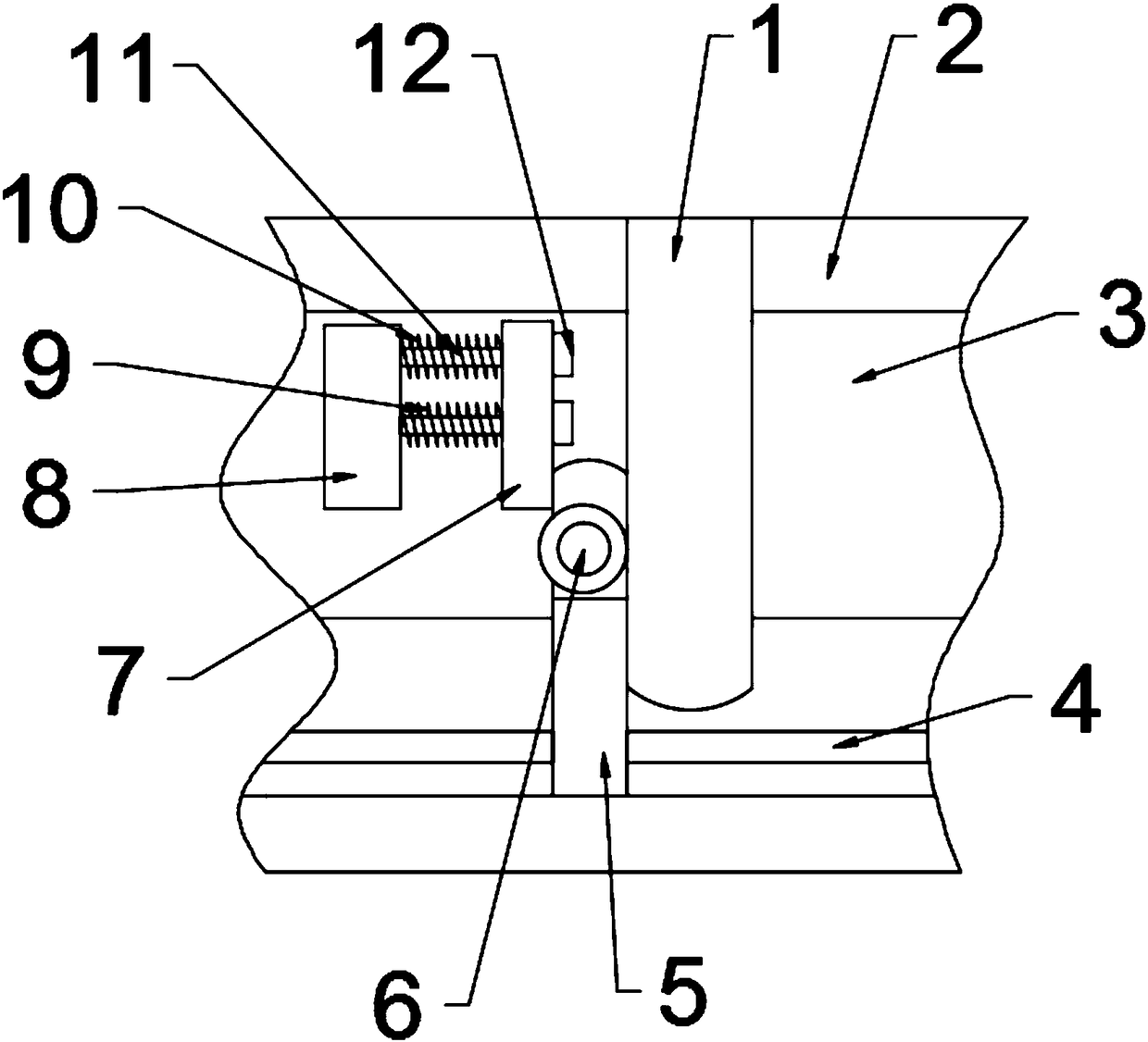

[0014] see figure 1 , an ejection mechanism of a plastic mold, comprising a movable mold 3, and a fixed mold 2 arranged above the movable mold 3; a push rod 4 is arranged at the lower end of the movable mold 3; a first reset is vertically arranged on the push rod 4 Rod 5; a roller 6 is arranged above the first reset lever 5; a stopper 7 is arranged on one side of the roller 6, and a second reset lever 1 is arranged on the other side; the stopper 7 is installed on the elastic reset assembly, The elastic return assembly includes a positioning seat 8, a mounting pin 9, a spring 11 and a locking cap 12. Two through holes with internal threads are transversely opened on the stopper 7, and the two mounting pins 9 pass through the through holes and Tighten in the mounting groove on the side of the positioning seat 8, the mounting pin 9 between the positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com