Vehicle-mounted luggage rack crossbar assembly

A luggage rack and crossbar technology, used in vehicle parts, additional accessories, transportation and packaging, etc., can solve problems such as poor versatility, inability to implement height adjustment, and stability to be considered.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

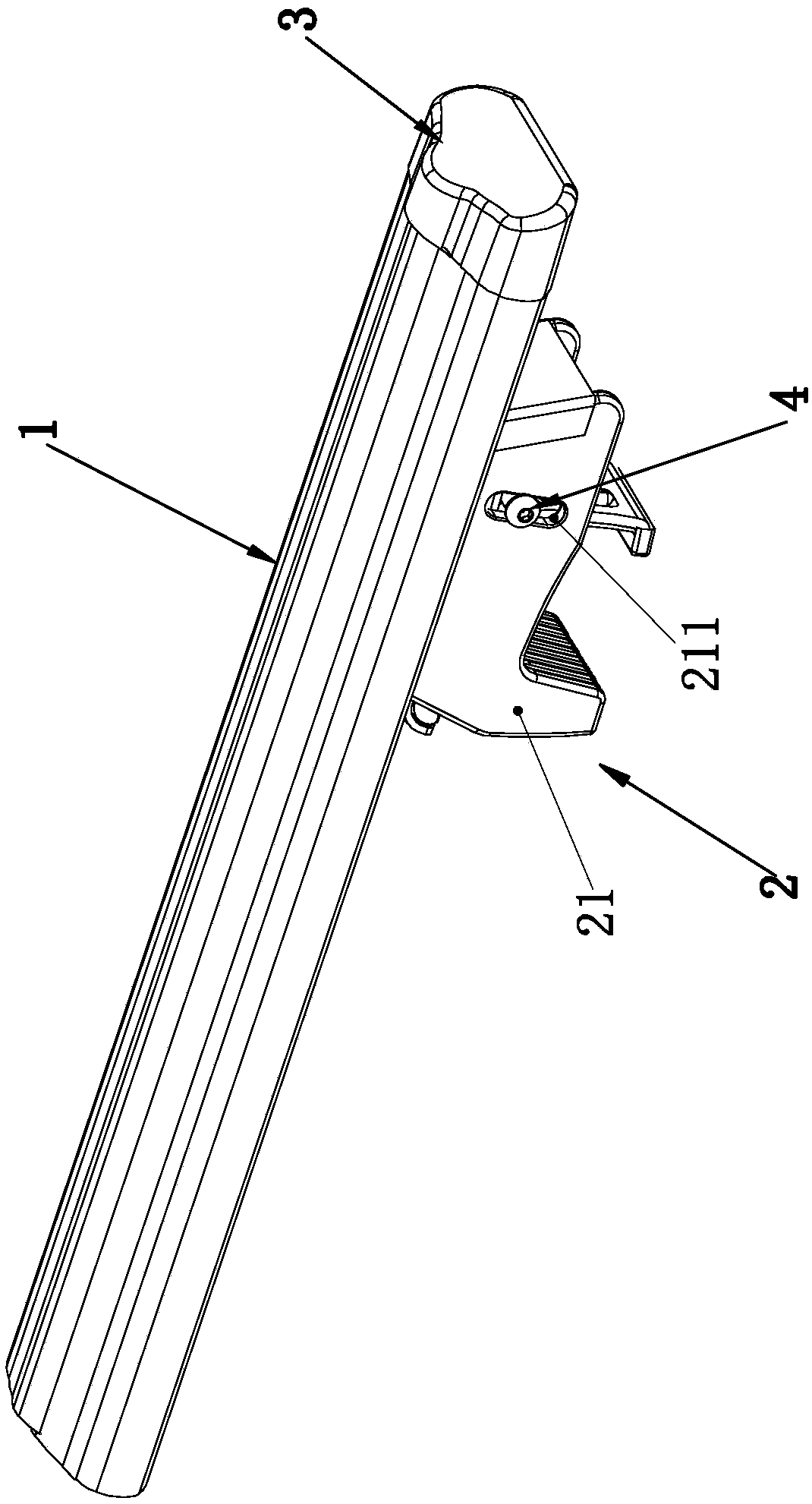

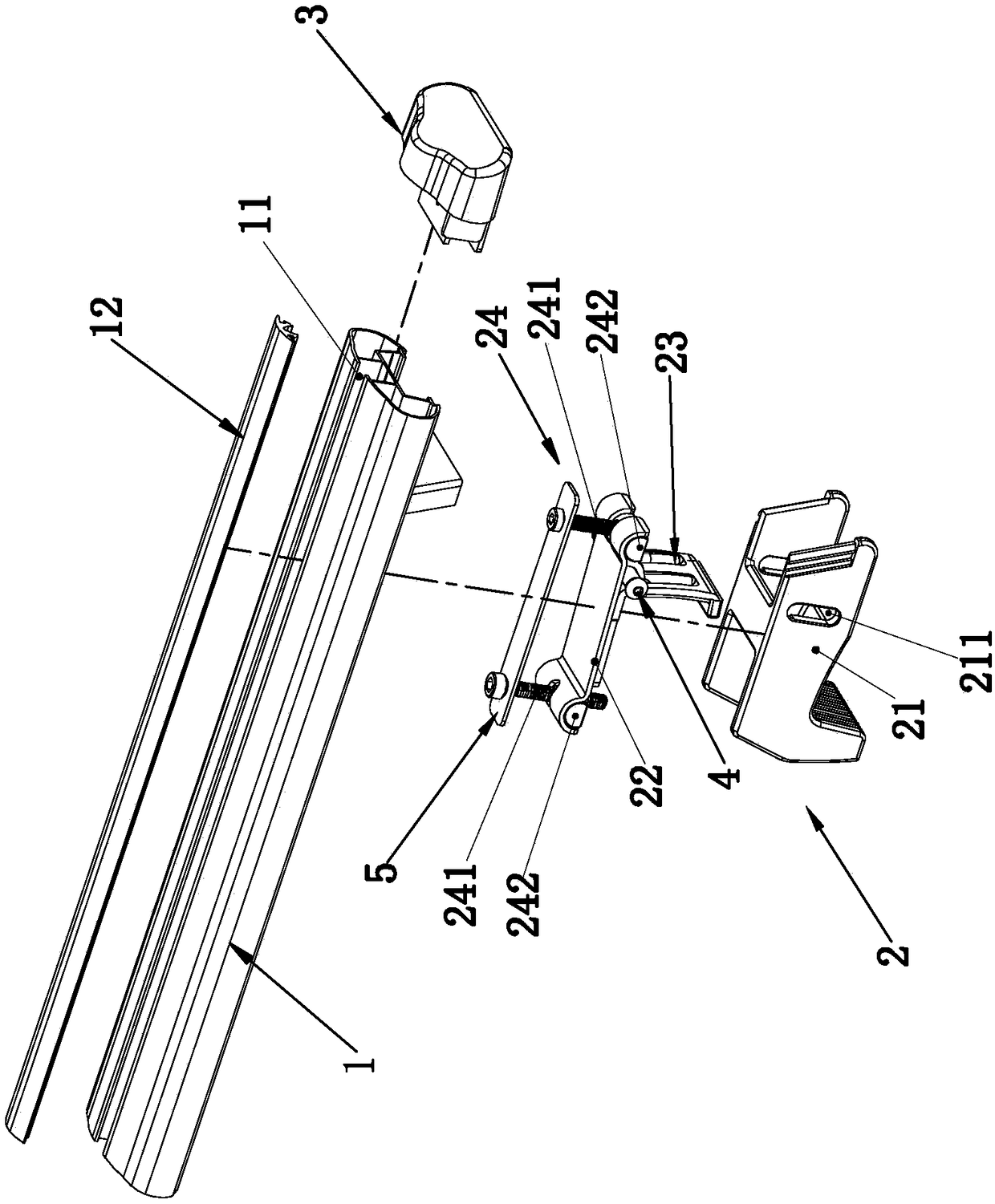

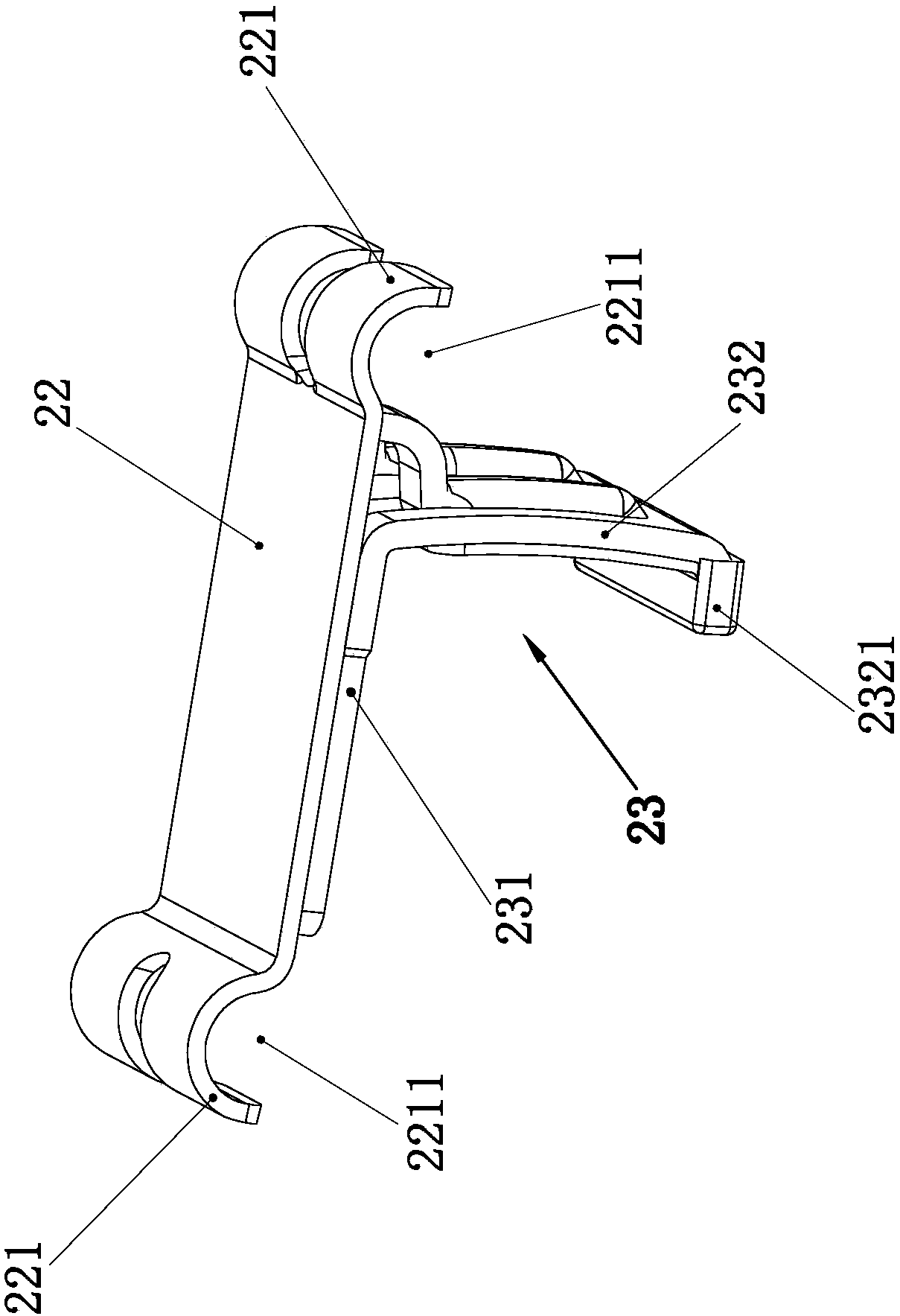

[0024] Such as figure 1 — image 3 A vehicle-mounted luggage rack crossbar assembly shown includes a crossbar 1 and a buckle 2 arranged on the crossbar 1 that can be connected to or removed from the luggage rack. The buckle 2 is installed on the crossbar 1 and the roof. On the end face of the rear end facing the roof, the fastening piece 2 includes a static clamping block 21 fixed on the cross bar 1 , an adjusting plate 22 erected on the cross bar 1 and hingedly connected with the static clamping block 21 1. A dynamic clamping claw 23 that connects with the adjustment plate 22 and can be opened and closed horizontally with the static clamping block 21 or vertically lifts along the static clamping block 21. A dynamic clamping claw 23 is provided between the cross bar 1 and the adjustment plate 22 The horizontal and vertical adjustment mechanism 24, the longitudinal ends of the cross bar 1 are respectively provided with locking sleeves 3 that are plugged and connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com