Molding formation equipment for paper pulp

A molding equipment, pulp molding technology, applied in textiles and papermaking, etc., can solve the problems of inability to adapt to huge demand, unstable product quality, slow production speed, etc., to improve dehydration effect and response speed, facilitate later maintenance, The effect of increasing production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

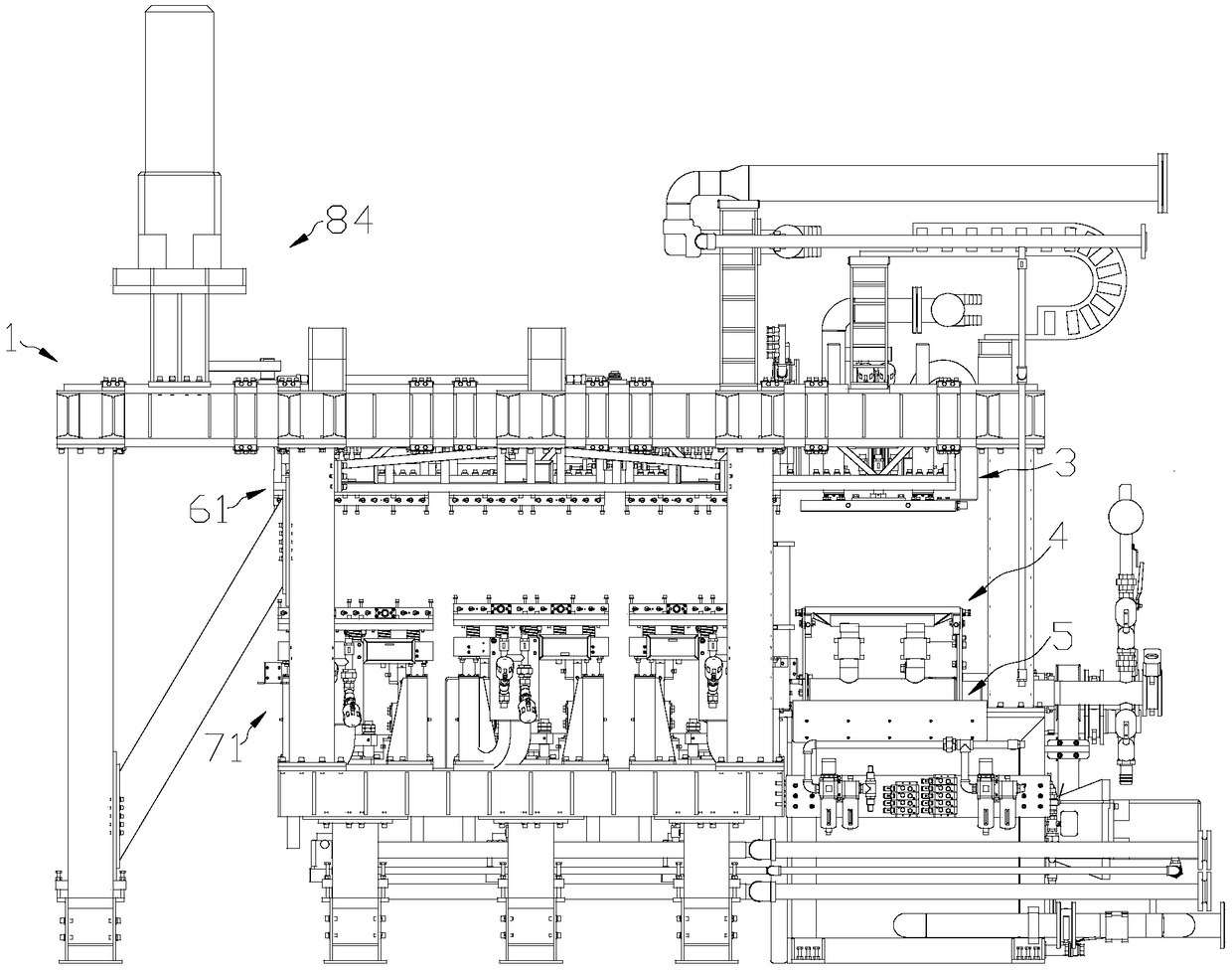

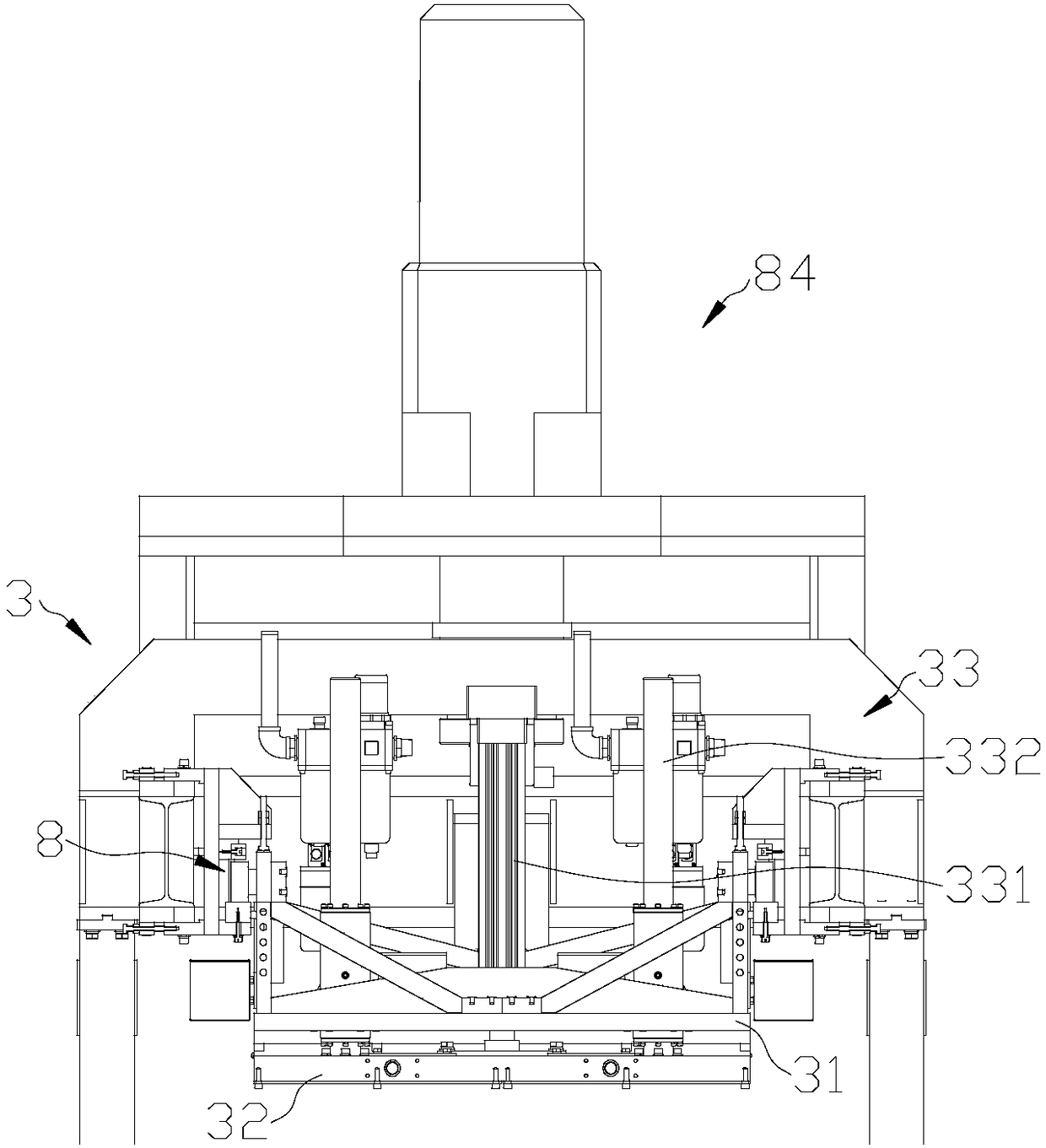

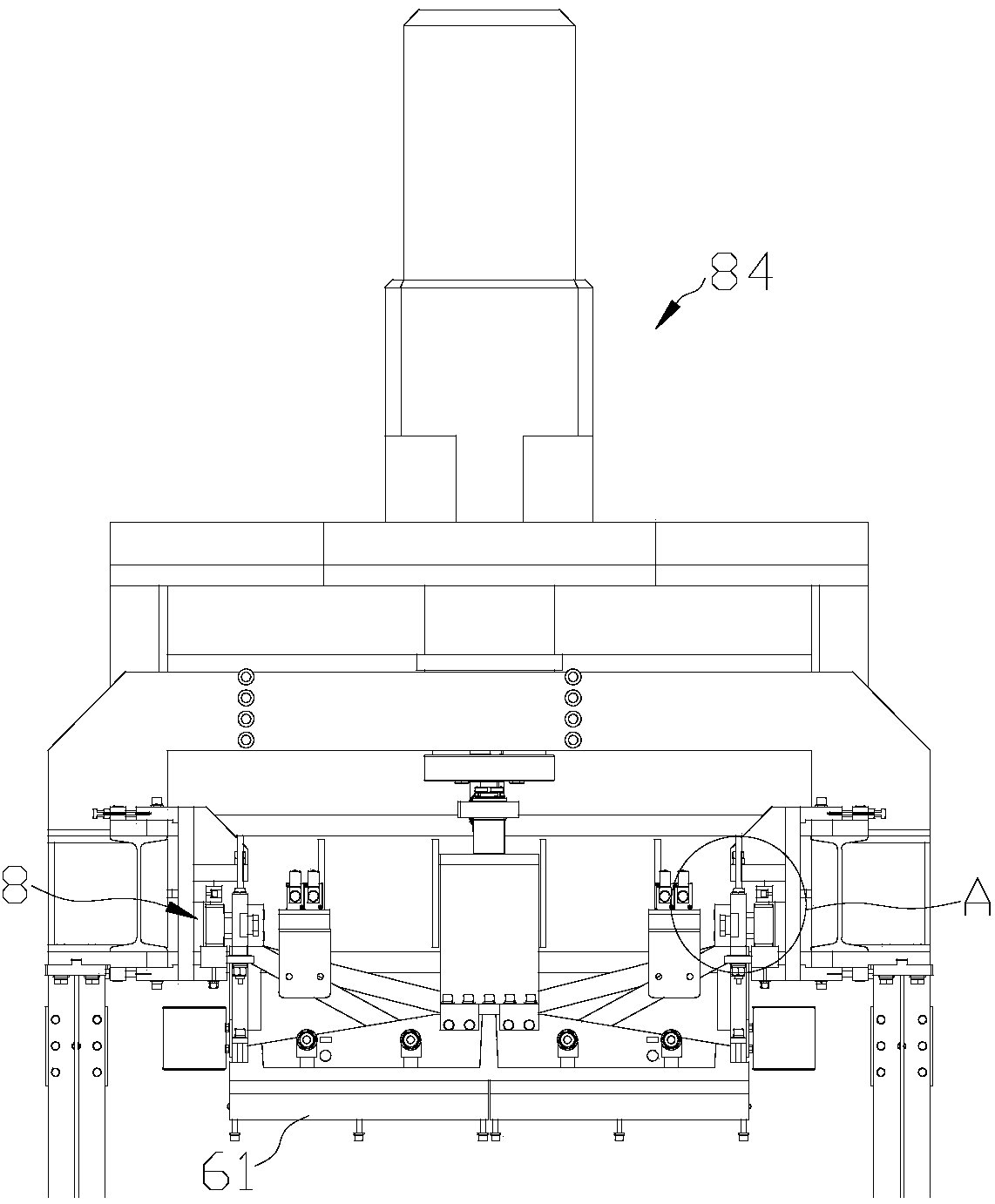

[0036] see Figure 1 to Figure 10 , a kind of pulp molding equipment of the present embodiment includes a frame 1, and a slurry tank 5 arranged on the frame 1, a wet billet forming mechanism 4, a wet billet transfer mechanism 3 and a hot-press shaping mechanism; The slurry box 5 is arranged at the bottom of the frame 1; the wet blank forming mechanism 4 is arranged in the slurry box 5, and the wet blank forming mechanism 4 absorbs the slurry in the slurry box 5 to prepare a paper mold wet blank; said wet blank transfer mechanism 3 is arranged above the frame 1 corresponding to said wet blank forming mechanism 4, and it is used to transfer the paper mold wet blank on said wet blank forming mechanism 4 to said hot-press shaping mechanism, The hot-press shaping mechanism is arranged on the frame 1 for hot-press shaping the wet blank of the paper mold.

[0037] Described hot-press shaping mechanism comprises vacuum suction device (not shown in the figure), ejector mechanism 72, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com