Telescopic shoes dryer

A shoe dryer and telescopic technology, applied in the field of shoe drying devices, can solve the problem that the shoe dryer cannot dry shoes of different sizes, and achieve the effects of avoiding rapid aging, increasing current, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Further detailed explanation through specific implementation mode below:

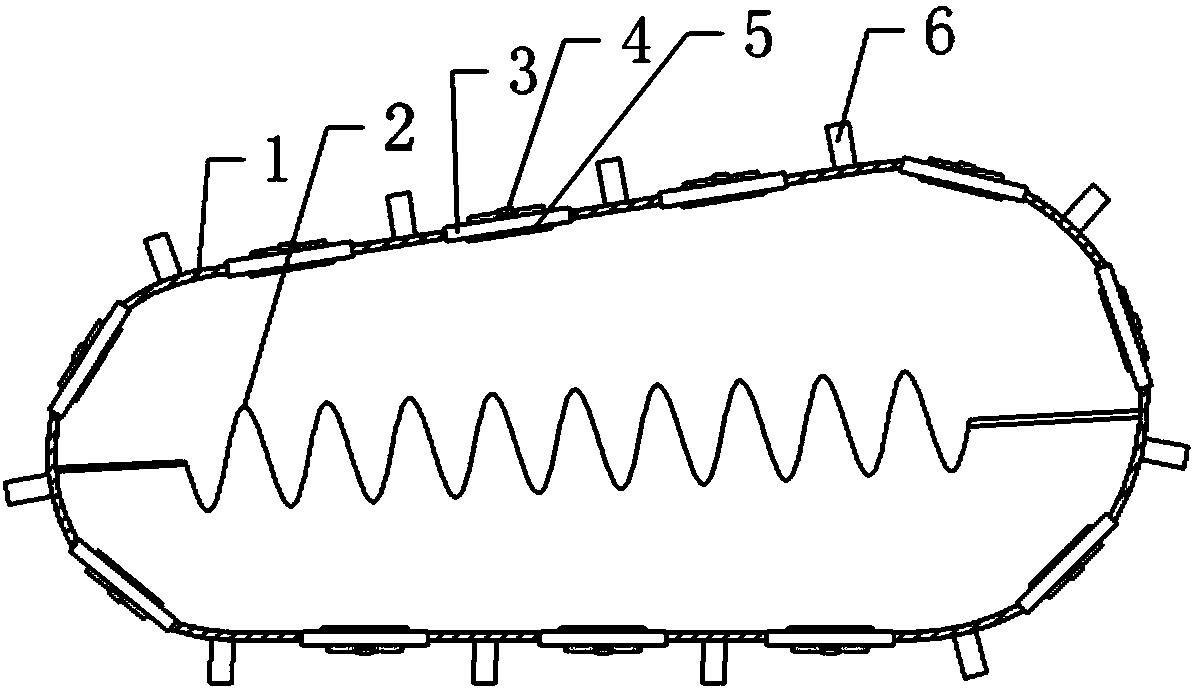

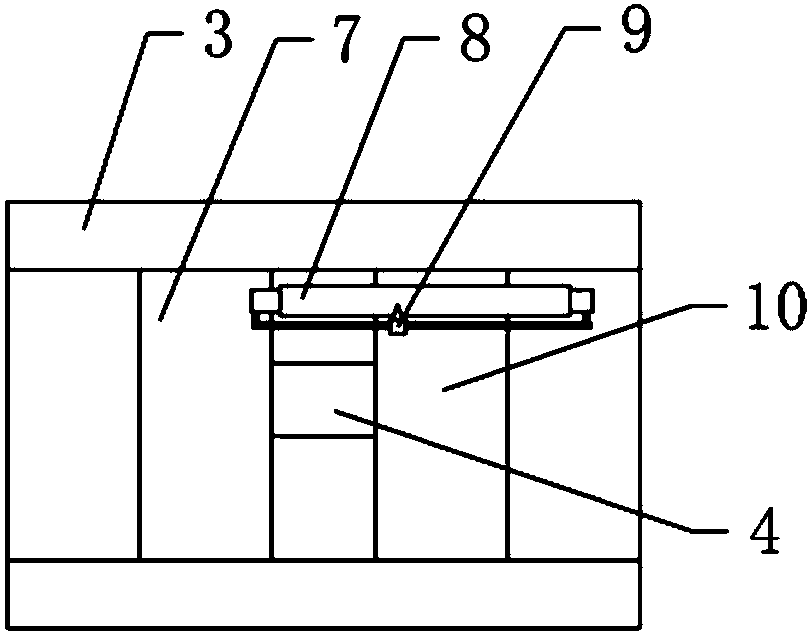

[0015] The reference signs in the accompanying drawings of the description include: elastic airbag 1, heating element 2, heat sink 3, water-absorbing expansion block 4, heat conduction block 5, protruding rod 6, first slider 7, resistance coil 8, sliding sheet 9, The second slider 10.

[0016] The embodiment is basically as attached figure 1 and figure 2 Shown: telescopic shoe dryer, including elastic airbag 1, inside elastic airbag 1 is equipped with heating element 2, heating element 2 is a resistance heating wire arranged in the shape of a helical spring, and connecting rods are fixed at both ends of heating element 2 , the connecting rod is preferably made of glass fiber. The end of the connecting rod far away from the heating element 2 is bonded to the elastic airbag 1, so that the heating element 2 is arranged laterally in the elastic airbag 1, and the length of the heating element 2 ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com