Manufacturing process of a new type of diamond synthesis column

A diamond synthesis column and manufacturing process technology, applied in the application of ultra-high pressure process, the method of using atmospheric pressure to chemically change substances, chemical instruments and methods, etc., can solve the problem of uneven catalyst ratio and achieve improved temperature Uniformity, yield improvement, and quality improvement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Take 500 parts by weight of the metal catalyst and 500 parts by weight of graphite, divide the metal catalyst into 10 parts, divide into 10 parts according to |d|=0.1, specifically 50.45, 50.35, 50.25, 50.15, 50.05, 49.95, 49.85, 49.75 , 49.65, 49.55, divide the graphite into 10 parts on average, each part is 50 parts by weight, mix one part of metal catalyst and one part of graphite evenly and press it into a 3mm graphite sheet, and press 10 parts of the pressed graphite sheet according to the metal The catalysts are arranged in a descending order from top to bottom to form layered graphite columns, and put into an iron cup to seal it. Put the iron cup into a six-sided top press, and keep it warm at 1500K and 5GPa for 20 minutes to produce diamond. synthetic column. During the manufacturing process, the arranged layered graphite columns and the prepared diamond synthesis columns are as follows: figure 1 shown.

Embodiment 2

[0041]Take 550 parts by weight of the metal catalyst and 550 parts by weight of graphite, divide the metal catalyst into 11 parts, divide into 11 parts according to |d|=0.1, specifically 50.5, 50.4, 50.3, 50.2, 50.1, 50.0, 49.9, 49.8 , 49.7, 49.6, 49.5, the graphite is divided into 11 parts on average, each part is 50 parts by weight, a part of metal catalyst and a part of graphite are mixed evenly and pressed into a 3mm graphite sheet, and 10 parts of the pressed graphite sheet Arrange the layered graphite columns in the descending order of metal catalysts from top to bottom, and put them into iron cups for packaging. Put the iron cups into a six-sided top press, and keep them warm at 1500K and 5GPa for 20 minutes to make them. Get a diamond synthetic column.

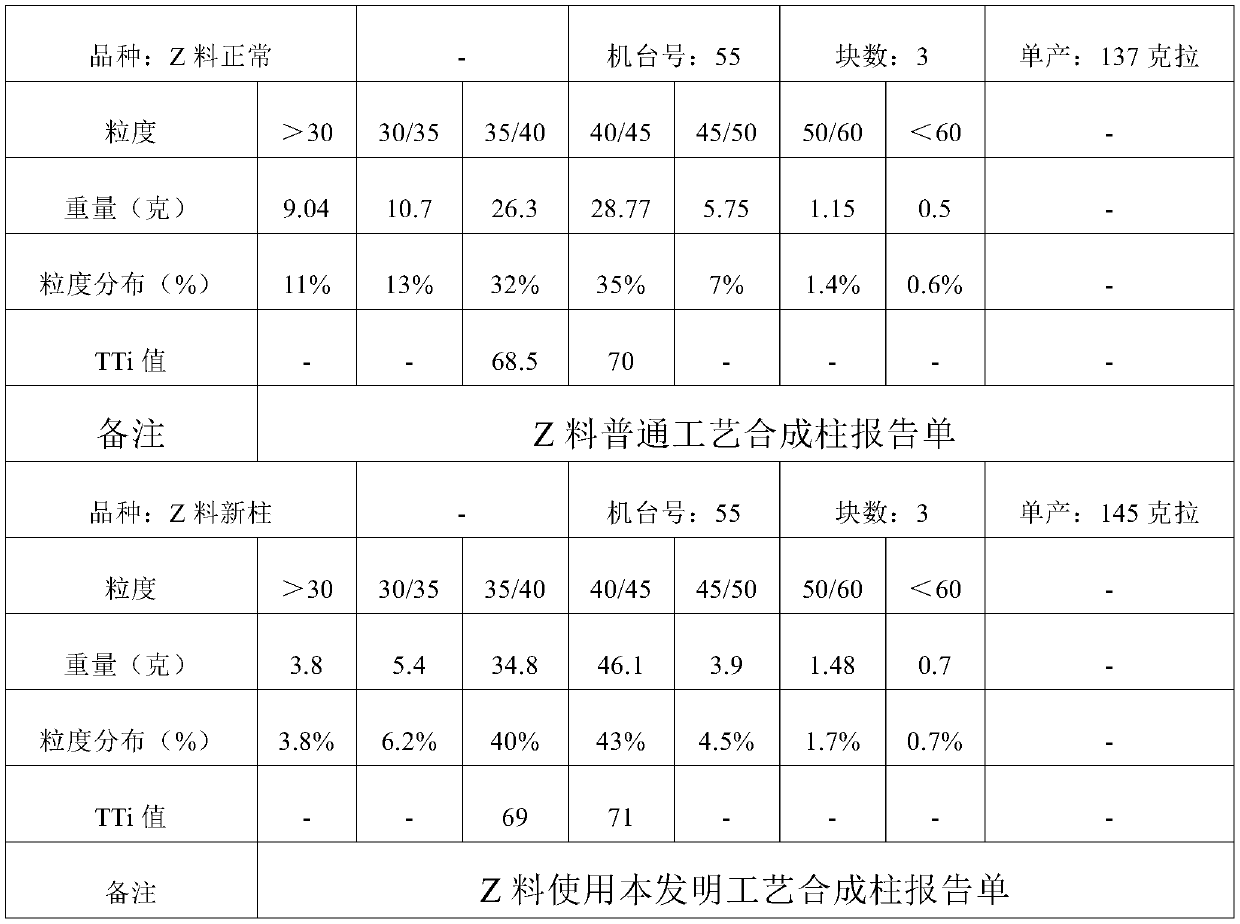

[0042] As shown in Table 1, the quality report sheets of the diamonds synthesized by the common process and the process synthesis column of the present invention are shown in Table 1. As can be clearly seen from Table...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com