A multi-layer ceramic painting device

A multi-level, ceramic technology, used in ceramic molding machines, manufacturing tools, auxiliary molding equipment, etc., can solve the problems of limited output, high price, and inability to meet needs, and achieve the effect of convenient use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

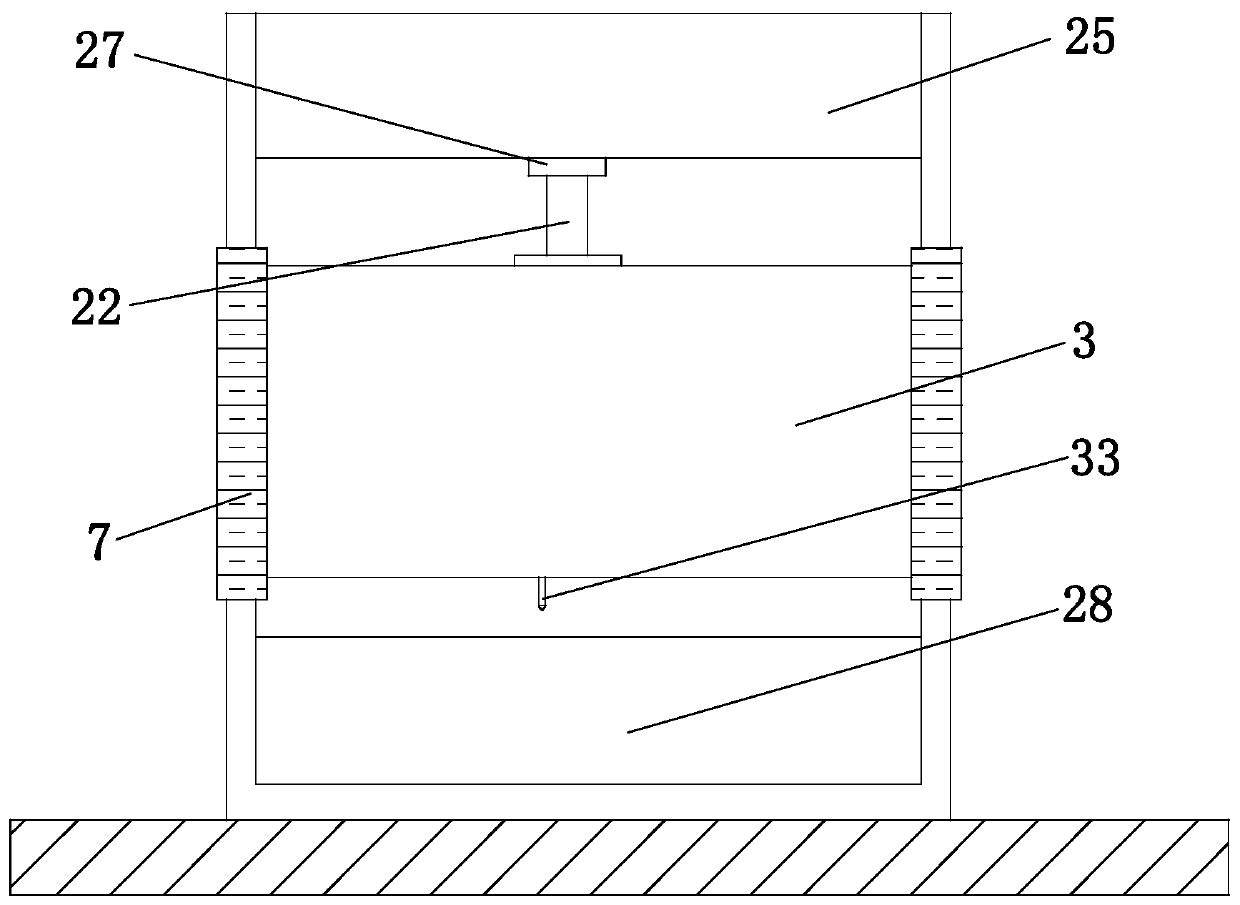

[0025] see Figure 1-6 , a multi-layered ceramic painting device, comprising a plane moving frame 3, a general control frame 25 and an operating table 28; the left half of the operating table 28 bottom plate is equipped with a first motor 16; the right side of the first motor 16 Side is provided with splint 15; The right side of described splint 15 is provided with left top plate 13; The center of the left side of described left top plate 13 is welded with output shaft 14; Described output shaft 14 runs through splint 15, and its left end is inserted in In the first motor 16; the right side of the left top plate 13 is provided with a right top plate 12; the right top plate 12 and the left top plate 13 can be used in conjunction with the ceramics to be processed that can be placed between the two elements; the right side of the right top plate 12 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com