A drying equipment for producing new material masterbatch

A technology of drying equipment and color masterbatch, which is applied to the dryer of static materials, drying solid materials, and drying gas arrangement, etc., can solve the problems of affecting the drying effect, unable to realize the movement of color masterbatch, waste of heat, etc., and achieve the effect. Ideal, prevent softening or even melting, reduce energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The drying equipment for producing new material color masterbatches of the present invention will be clearly and completely described below with reference to the accompanying drawings.

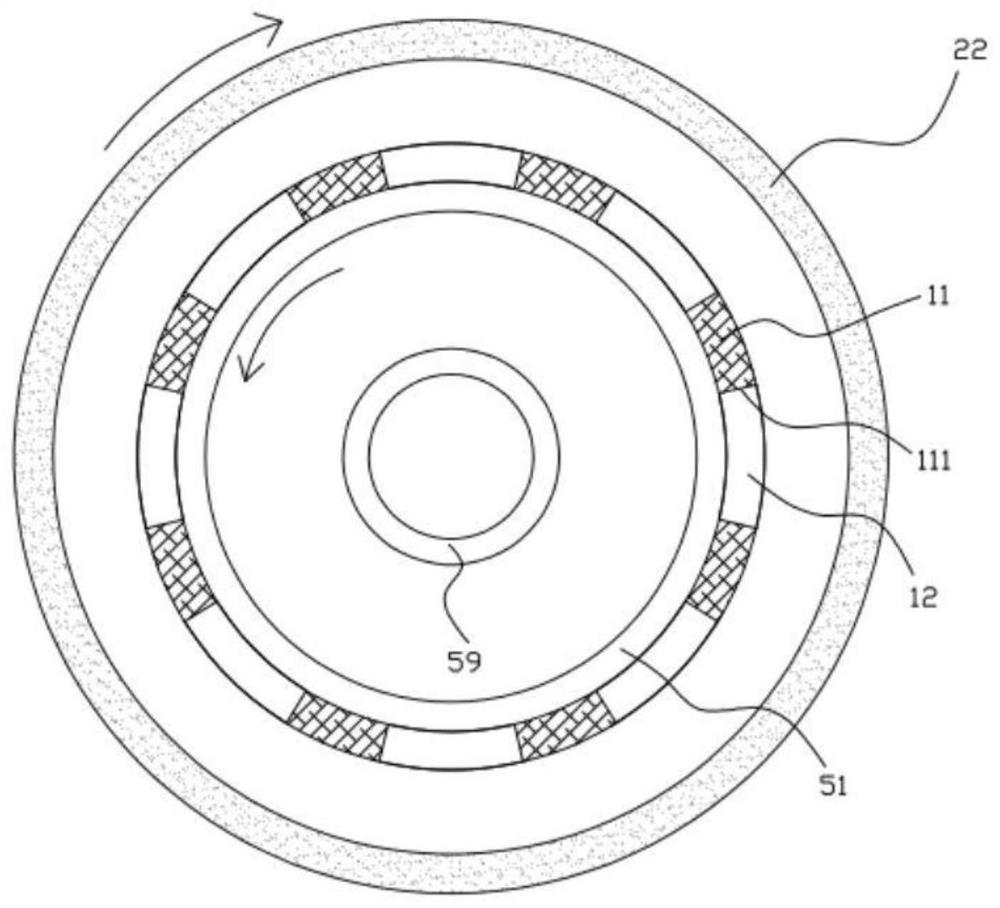

[0023] like Figure 1 to Figure 5 As shown, the drying equipment for producing new material color masterbatches of the present invention comprises an outer frame structure 1, a rotary air jet structure 2 arranged outside the outer frame structure 1, a driving structure 3 for driving the rotary air jet structure 2, and a set of The cover frame structure 4 is above the outer frame structure 1 , the concentration structure 5 is arranged in the outer frame structure 1 , and the lift drive structure 6 is arranged below the concentration structure 5 .

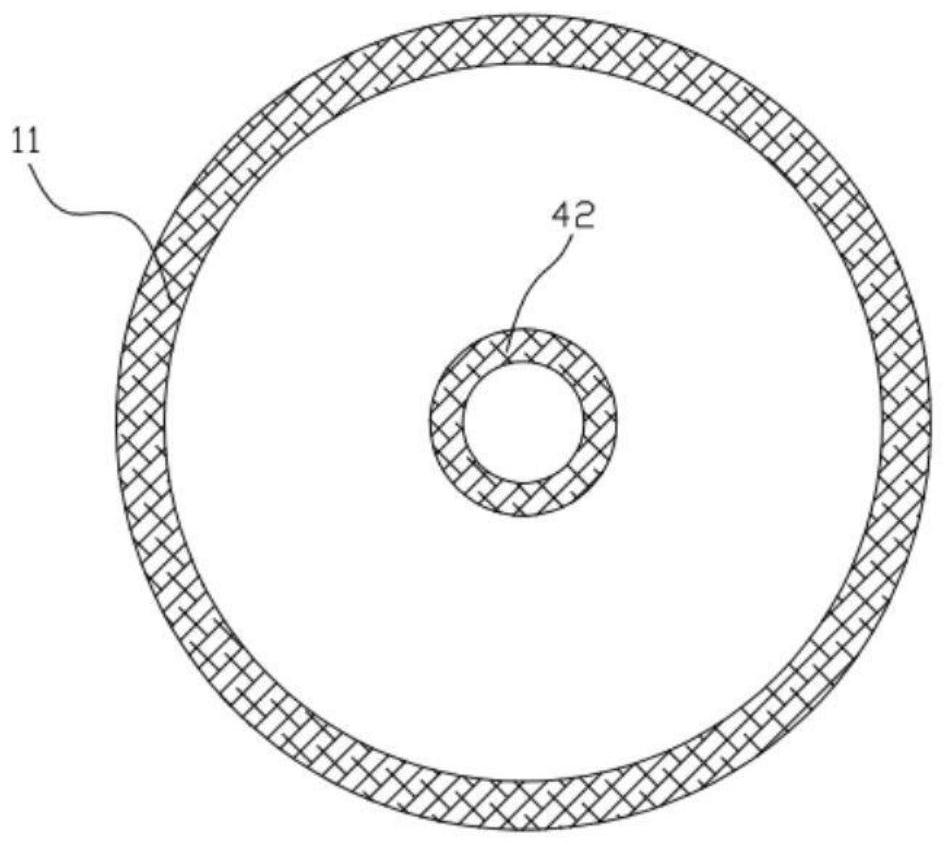

[0024] like Figure 1 to Figure 4 As shown, the outer frame structure 1 includes an outer frame 11 , a plurality of first filters 12 disposed on the outer wall of the outer frame 11 , and a plurality of limiting blocks 13 disposed in the oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com