Explosion-proof control box for high gas tunnel trolley

A control box and gas technology, which is applied in the direction of chassis/box/cabinet/drawer parts, electrical equipment shell/cabinet/drawer, instruments, etc. Safety hazards and other issues, to achieve the effect of reducing impact force, improving universality, and convenient installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

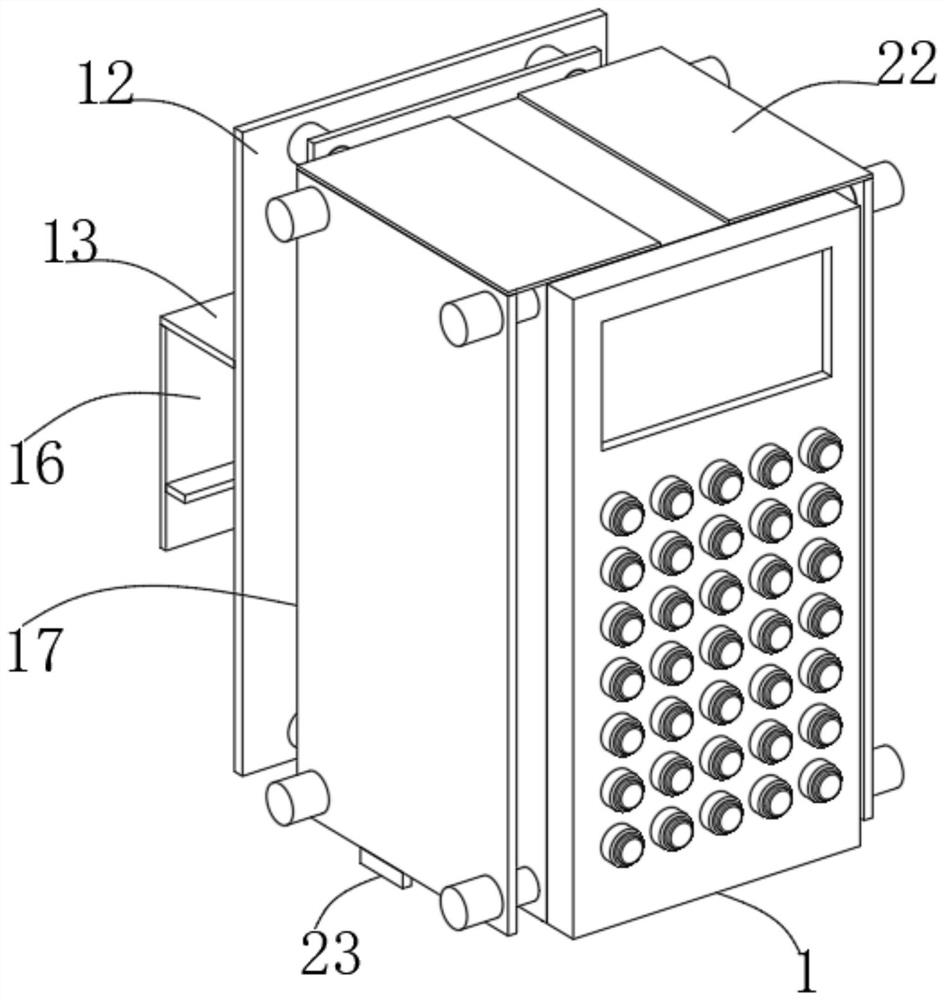

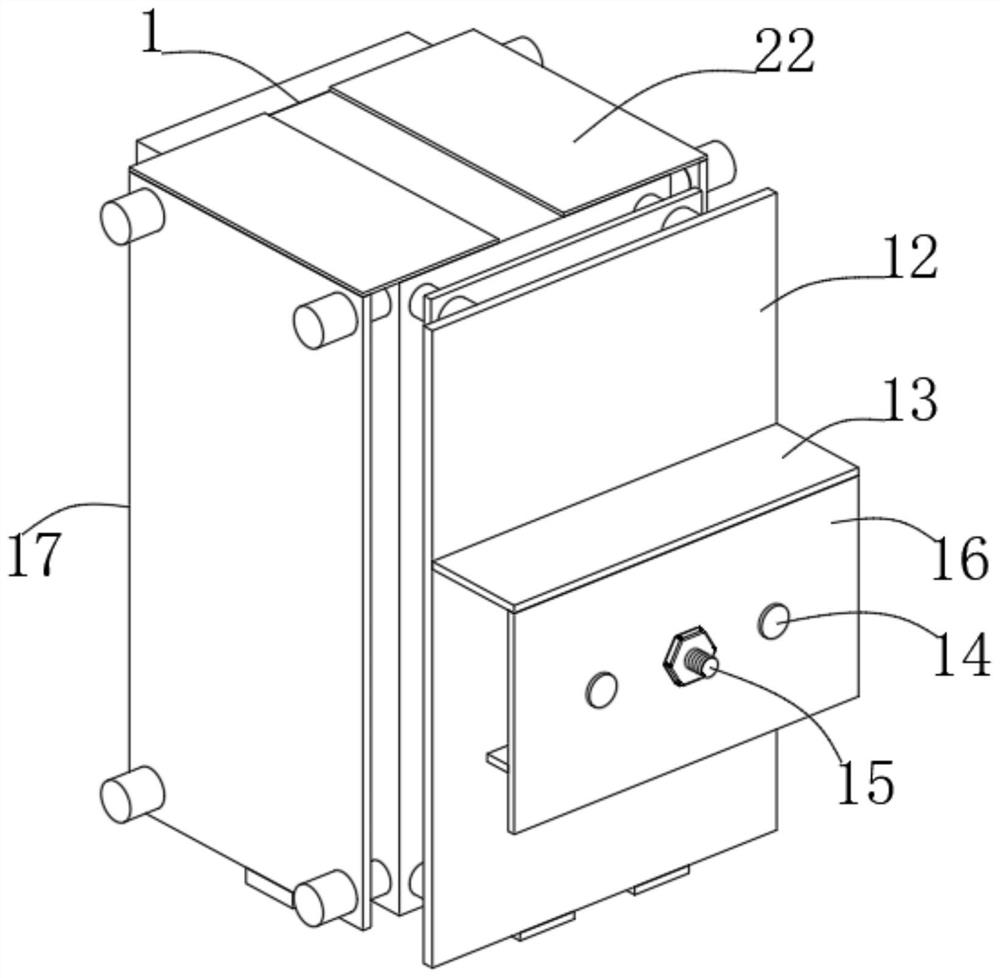

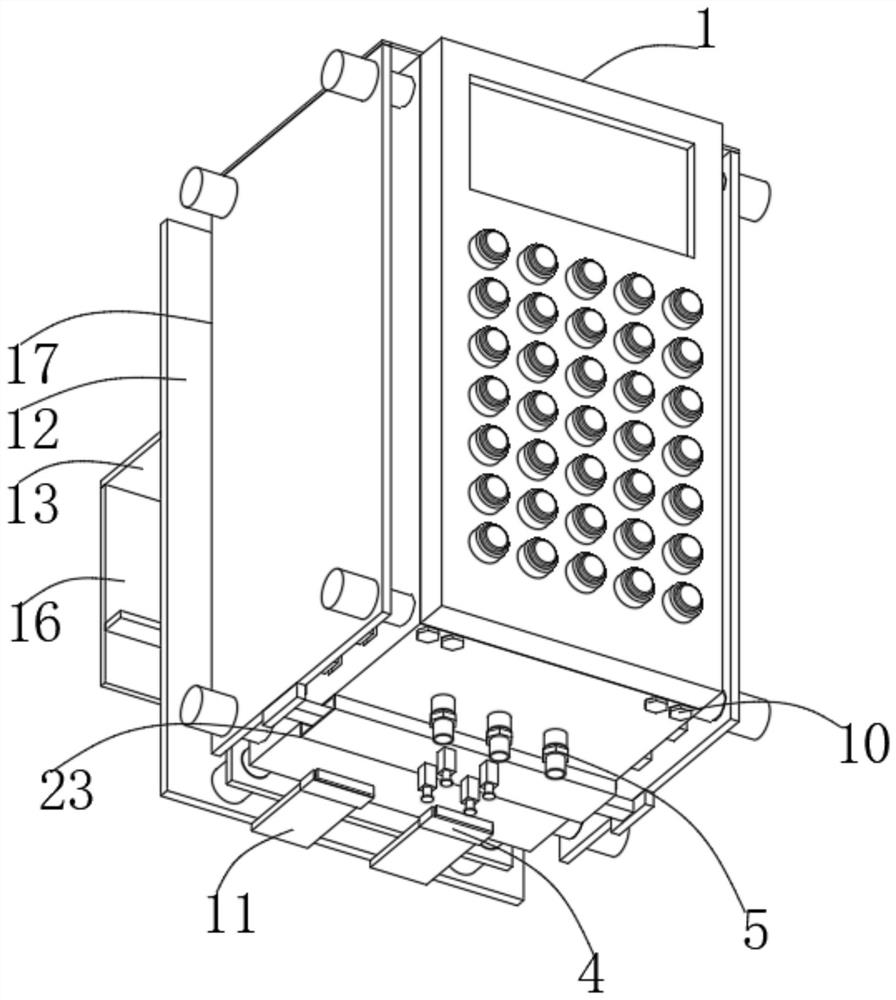

[0040] Embodiment one, with reference to Figure 1-10 : Explosion-proof control box for high gas tunnel trolley, including storage mechanism 1, storage mechanism 1 includes protective frame 2 and protective cover 9, the establishment of protective frame 2 provides the installation basis for setting other functional components of the equipment, and at the same time effectively performs internal functions of the equipment The safety protection of components, through the setting up of the protective cover 9 and the protective frame 2, can effectively carry out the safety protection of the internal functional parts of the equipment. The outer surfaces of both sides of the protective frame 2 are equidistantly provided with three air vents along the horizontal direction. It can effectively discharge the excess heat inside the protective frame 2, so that the internal functional components of the equipment can realize their due functions for a long time. The outer surface of the side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com