Clamping feeding device

A technology of clamping feeding and clamping parts, which is applied in the direction of conveyor, transportation and packaging, etc., and can solve the problems of material deformation, influence and influence on material movement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

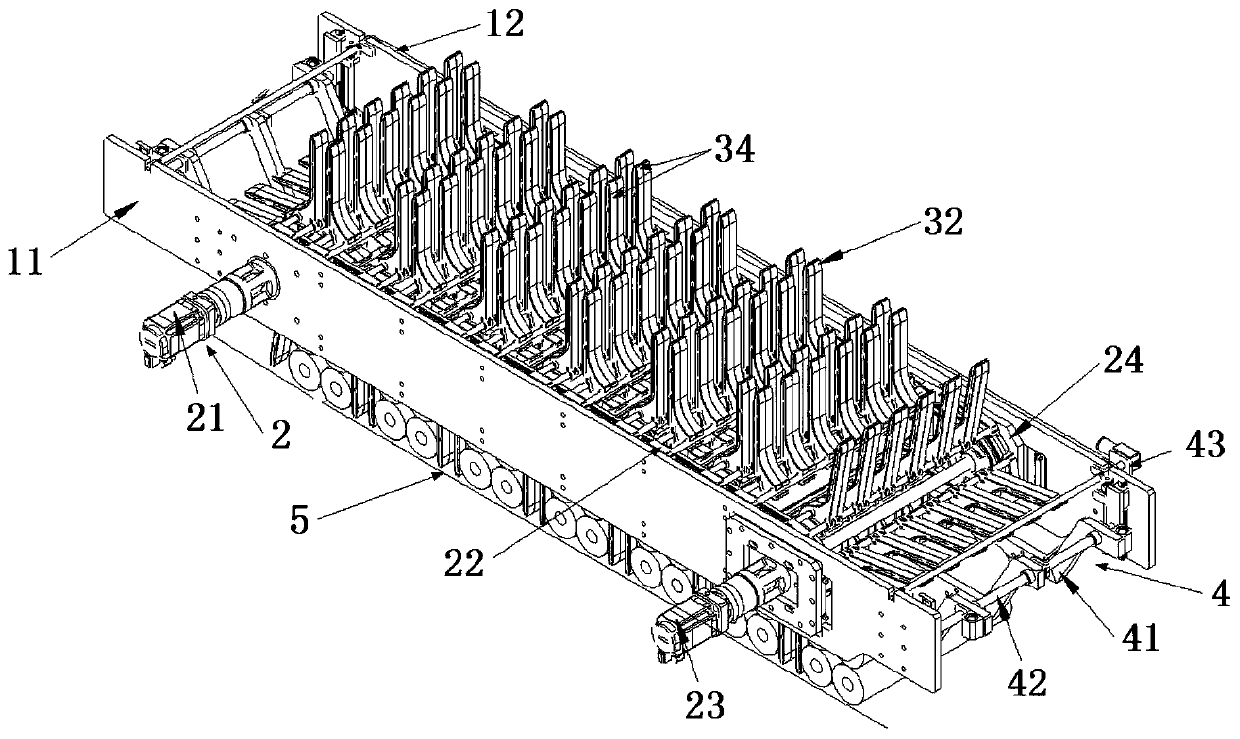

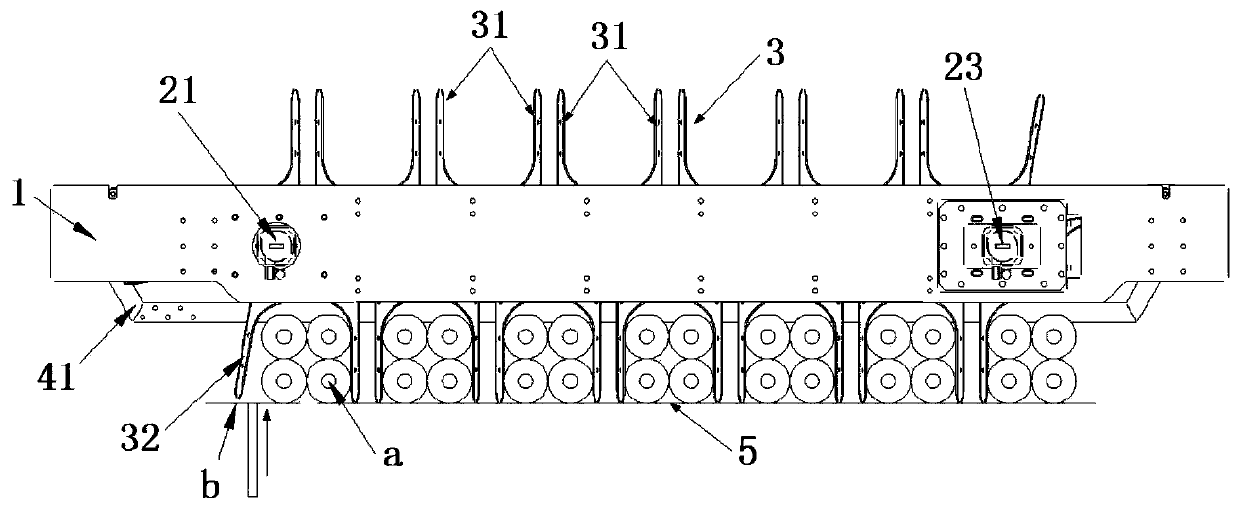

[0074] A clamping feeding device, comprising:

[0075] Mounting frame 1;

[0076] The power assembly 2 installed on the mounting frame;

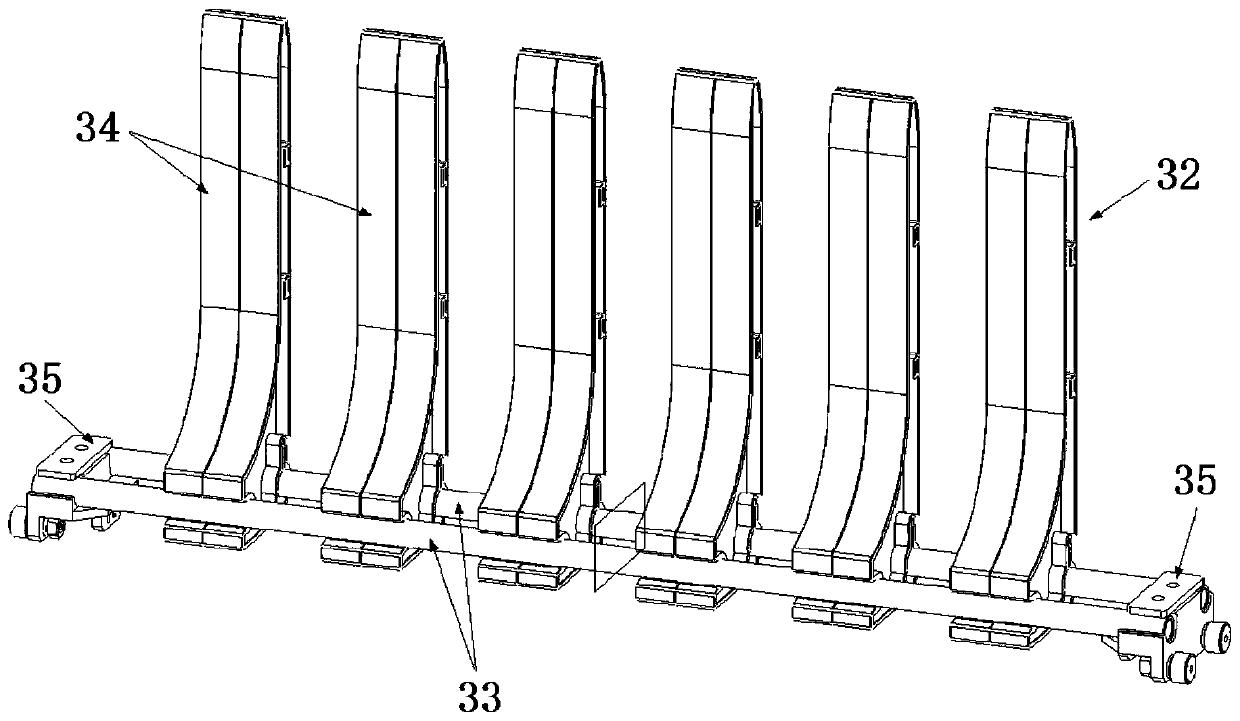

[0077] A gripper assembly 3 driven by the power assembly 2, the gripper assembly 3 includes sixteen grippers 31, the grippers 31 are composed of two opposite grippers 32;

[0078] The power assembly 2 includes a first power source 21, a first transmission mechanism 22, a second power source 23, and a second transmission mechanism 24, and the first transmission mechanism 22 and the second transmission mechanism 24 are respectively connected to one clamp 31 The different clamping parts 32 are connected, and the first transmission mechanism 22 and the second transmission mechanism 24 are independently driven by the first power source 21 and the second power source 23, so as to realize two clamping parts 32 close to or far away from each other.

[0079] The first transmission mechanism 22 and the second transmission mechanism 24 are annular c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com