Material lifting platform and lifting method thereof

A platform and material technology, applied in the field of material lifting platform, can solve the problems such as the inability to carry out secondary lifting of the stacking platform and the complicated process, so as to reduce the risk of high-altitude construction, simplify the lap joint process, and carry a large amount of materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A material lifting platform is used in the construction of high-rise buildings. In this embodiment, the lower frame structure of the high-rise building is pre-embedded and has strength.

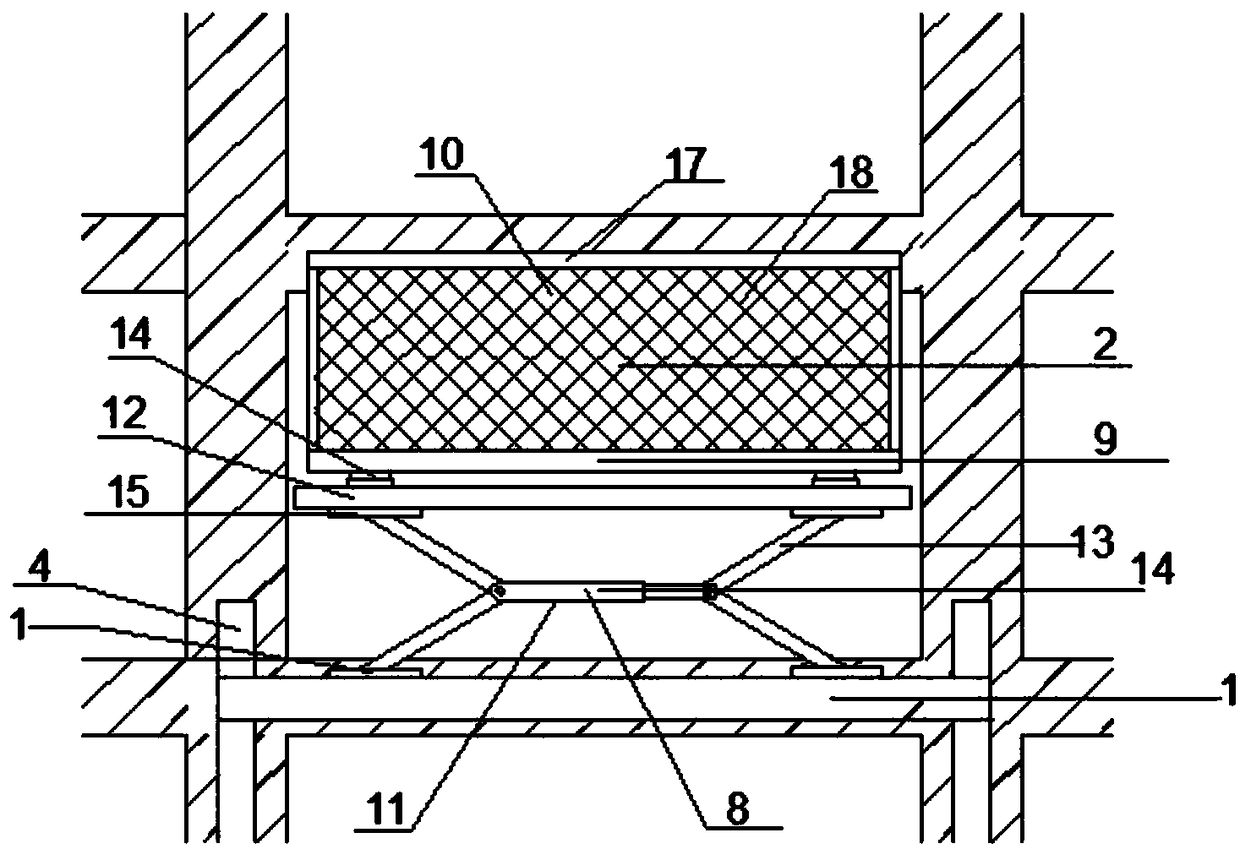

[0050] Such as figure 1 As shown, a material lifting platform includes a rectangular platform 1 fixed on a construction component and a hoist 2 arranged on the rectangular platform.

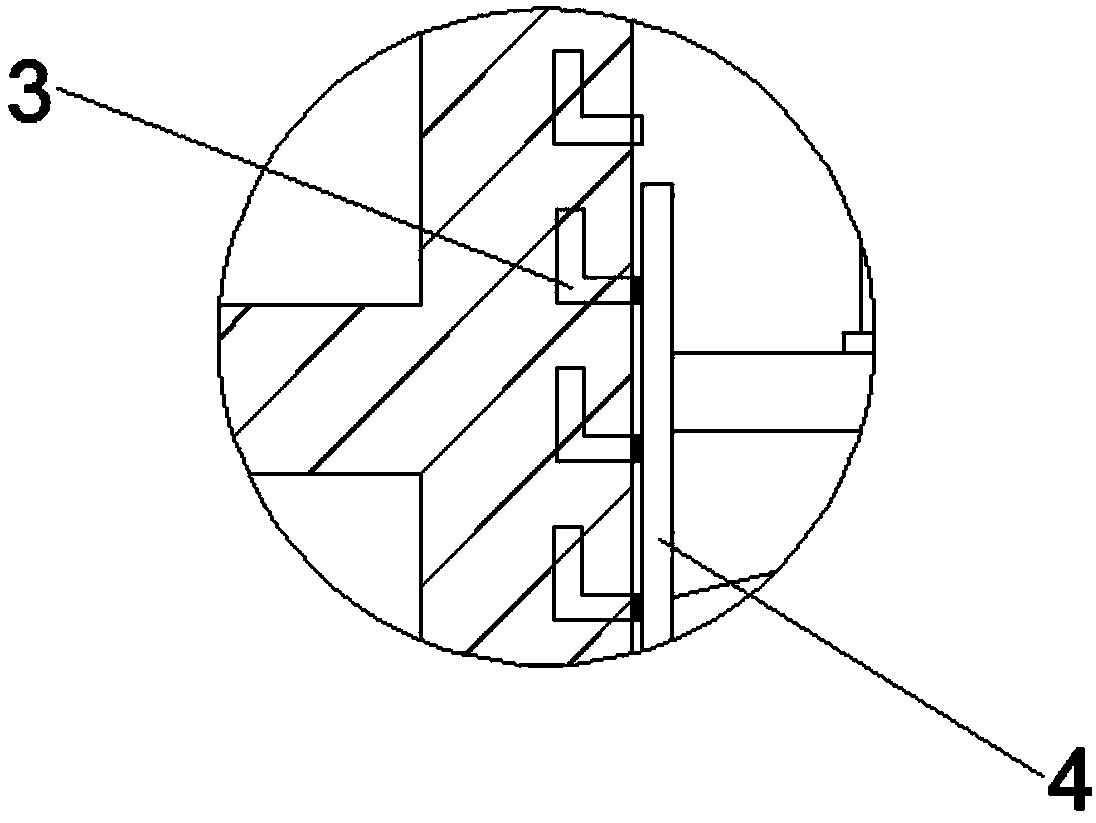

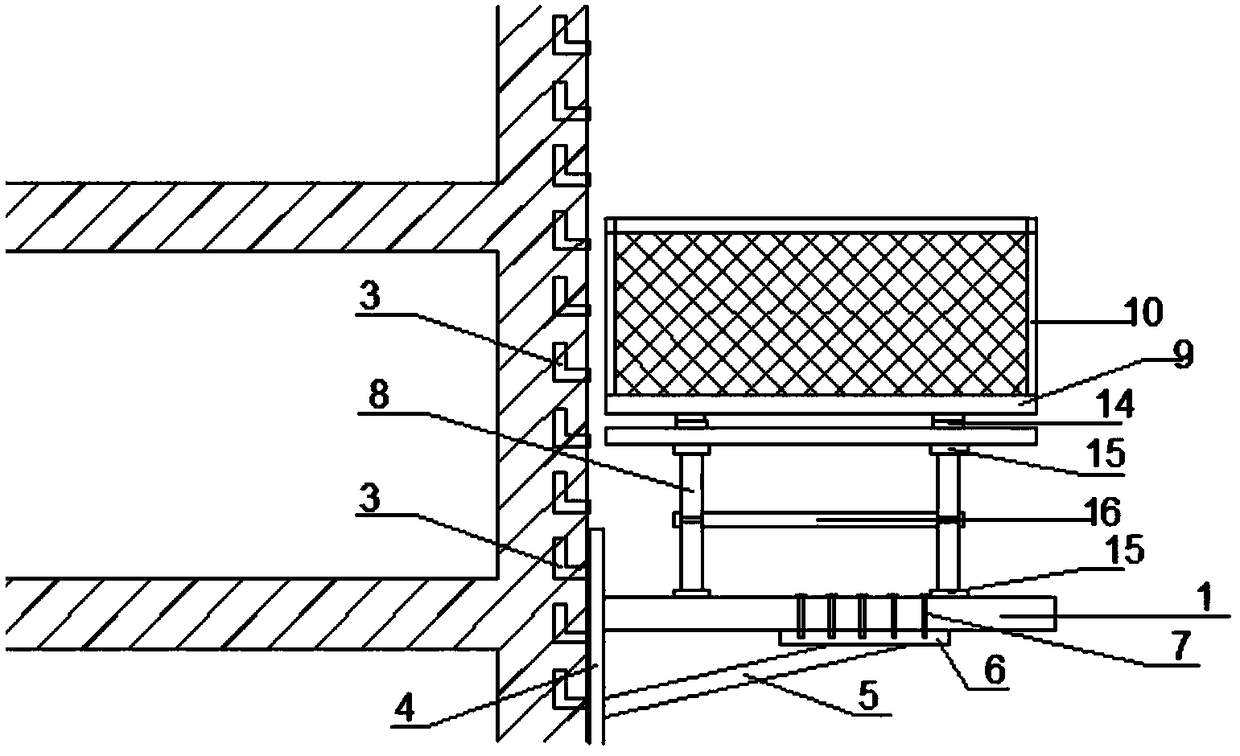

[0051] Such as figure 2As shown, an "L"-shaped steel member 3 is reserved on the side of the construction member, and a rectangular strip 4 is welded on the embedded steel member of the lower construction member. Such as image 3 As shown, the rectangular platform is fixed on the rectangular slat, and a fixed support 5 is provided below the rectangular platform. One end of the fixed support is fixed on the rectangular slab, and one end is connected to the bottom of the rectangular platform. The first fixed plate 6 is welded on the end of the fixed support in contact with the rectangular platform, and ...

Embodiment 2

[0063] A material lifting platform is used in the construction of high-rise buildings. In this embodiment, the lower frame structure of the high-rise building is pre-embedded and has strength.

[0064] Such as figure 1 As shown, a material lifting platform includes a rectangular platform 1 fixed on a construction component and a hoist 2 arranged on the rectangular platform.

[0065] Such as figure 2 As shown, an "L"-shaped steel member 3 is reserved on the side of the construction member, and a rectangular strip 4 is welded on the embedded steel member of the lower construction member. Such as image 3 As shown, the rectangular platform is fixed on the rectangular slat, and a fixed support 5 is provided below the rectangular platform. One end of the fixed support is fixed on the rectangular slab, and one end is connected to the bottom of the rectangular platform. The first fixed plate 6 is welded on the end of the fixed support in contact with the rectangular platform, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com