Pit digging machine

A technology of a pit digging machine and a traveling mechanism is applied to the pit digging machine. It can solve the problems of easy damage and hidden dangers of digging machines, and achieve the effect of preventing bending or even damage, not easy to blow out, and low requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

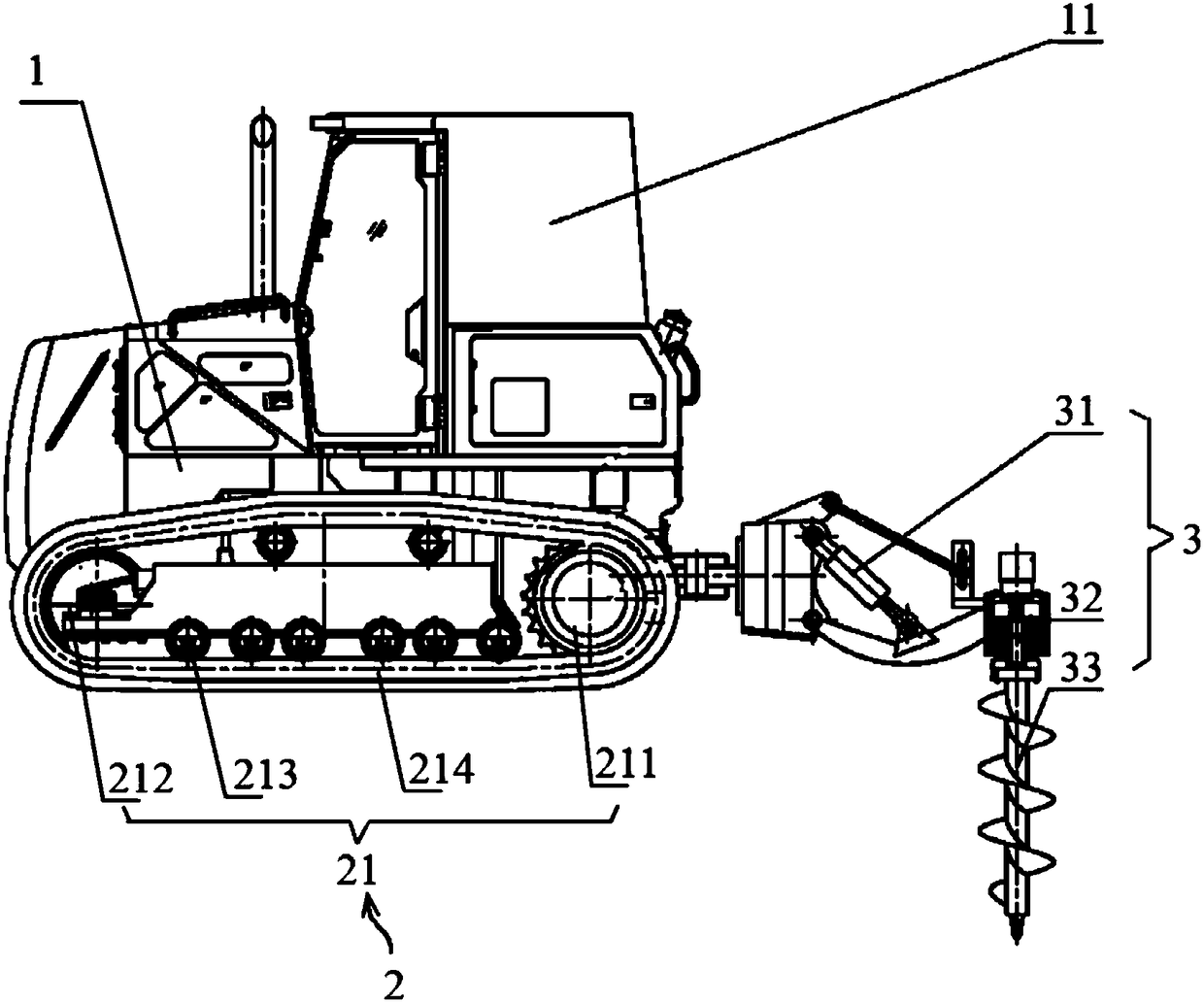

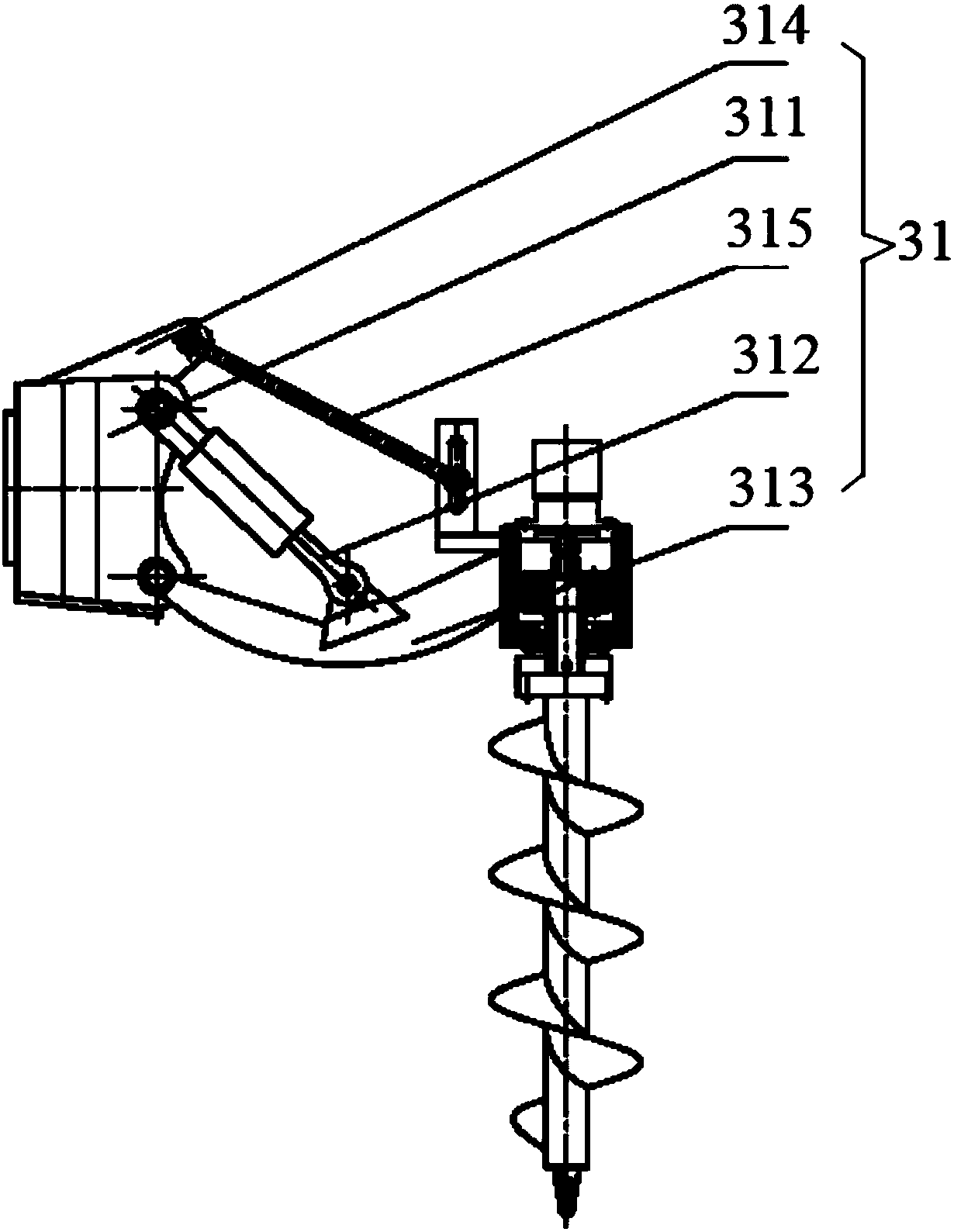

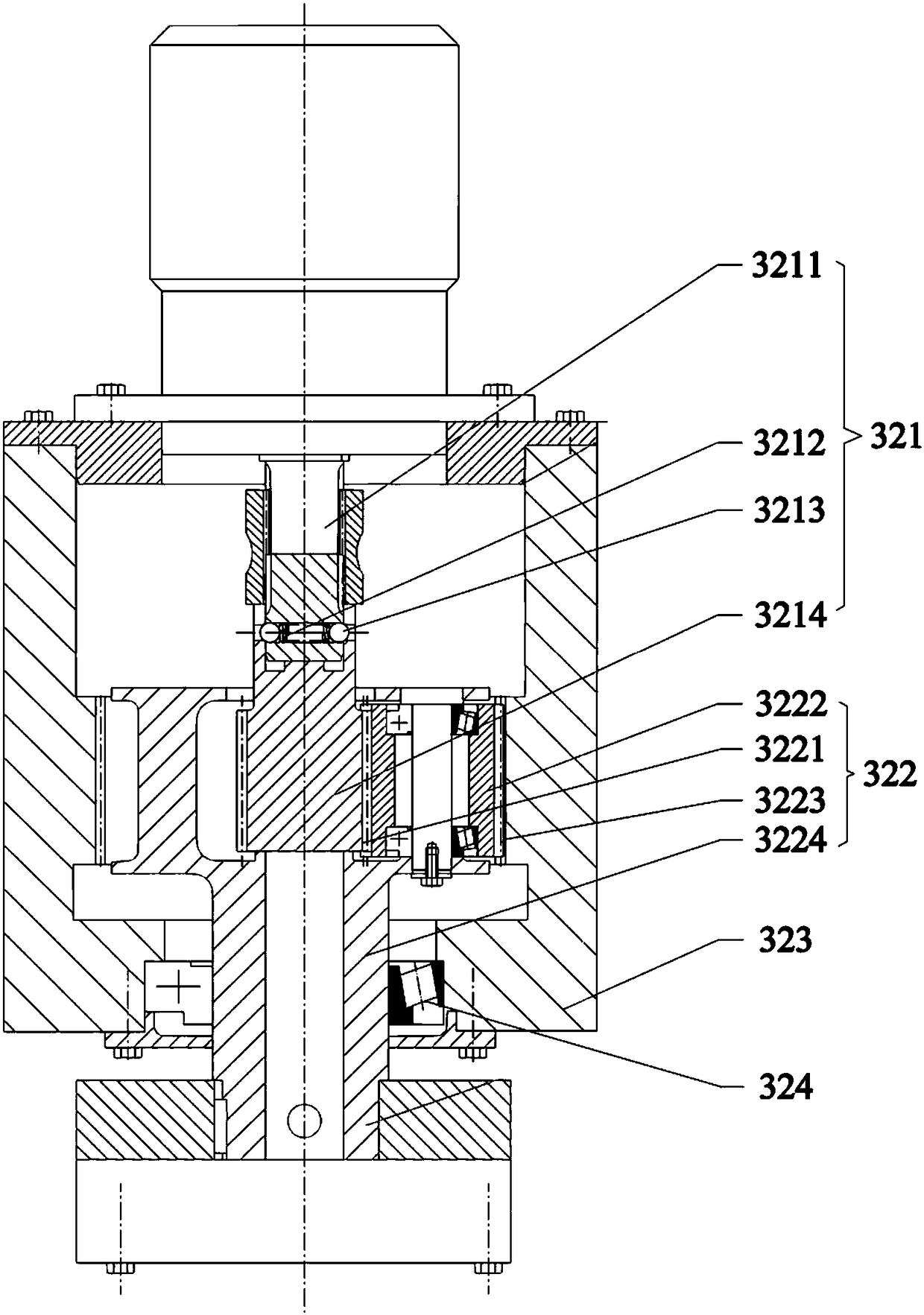

[0039] like figure 1 As shown, this embodiment discloses a digging machine, which mainly includes a vehicle frame 1, a cab 11 installed on the vehicle frame 1, a running mechanism 2 installed at the bottom of the vehicle frame 1, and a Digging mechanism 3. Wherein, the traveling mechanism 2 includes a crawler belt assembly 21 and a driving device for driving the crawler belt assembly 21 to move; the digging mechanism 3 includes a lifting assembly 31, a deceleration assembly 32, a motor and a digging head 33, and one side of the lifting assembly 31 is connected to the head of the vehicle frame 1. The other side is fixedly connected with the deceleration assembly 32, and the digging head 33 is connected to the output end of the deceleration assembly 32 bottom.

[0040] Specifically, the track assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com