Grinding device capable of achieving grinding for multiple times

A technology of multiple grinding and grinding grooves, which is applied in grain processing and other directions, can solve the problems of grinding and refining the grinding material that cannot be divided by the number of grindings, and achieve the effect of reducing resistance, increasing grinding times and reducing loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

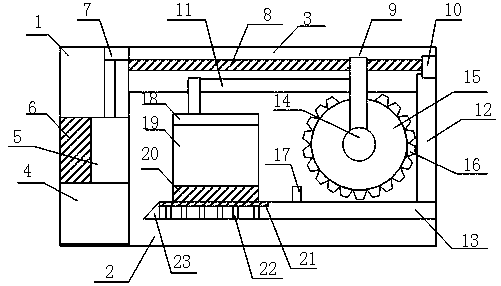

[0011] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

[0012] Such as figure 1 As shown, a multiple grinding device includes a motor slot 1, a raw material slot 2, an extension rod 3, a power supply 4, a rotating shaft box 5, a driving motor 6, a driving shaft 7, a raw material transmission belt 8, a bracket 9, and a buckle 10 , auxiliary connecting rod 11, longitudinal grinding groove 12, transverse grinding groove 13, runner 14, grinding disc 15, locking teeth 16, block 17, cover plate 18, briquetting block 19, fine stone plate 20, bottom plate 21, vibrating rod 22 and The slide table 23, the power supply 4 is installed at the bottom of the motor slot 1, the driving motor 6 is installed above the power supply 4, the rotating shaft box 5 is connected with the driving motor 6, the driving shaft 7 is connected with the rotating shaft box 5 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com