A ceramic creping scraper assembly for paper production

A technology of ceramics and components, which is applied in the field of ceramic wrinkling scraper components for paper production. It can solve the problems of inability to wrinkle, reduce production efficiency, and deteriorate softness, so as to prolong the online use time, prolong the use time, and save labor costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

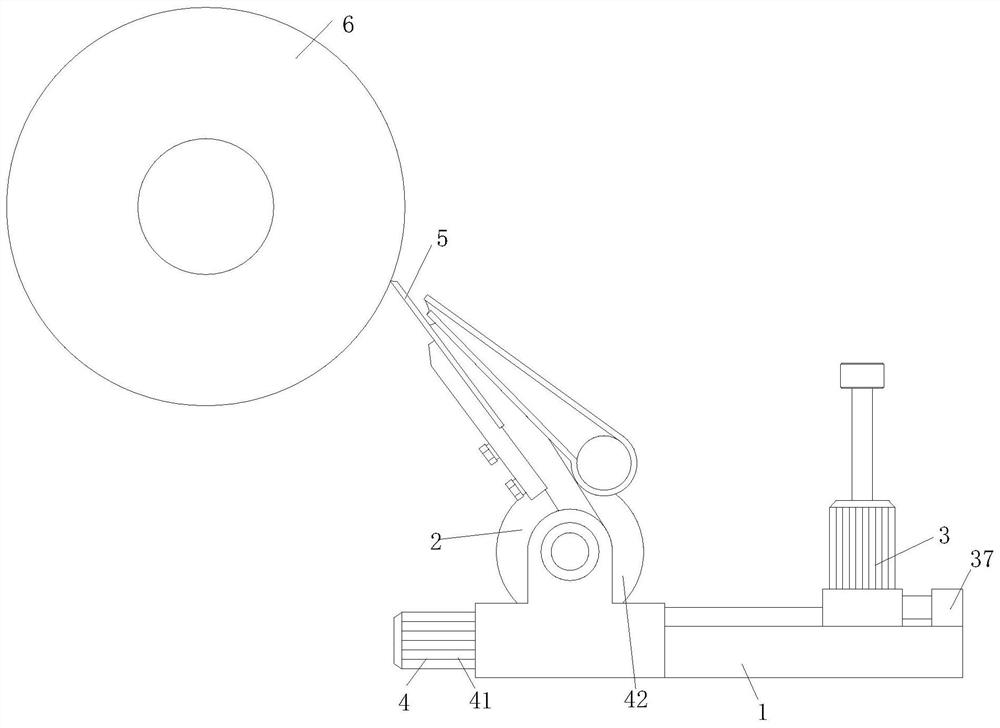

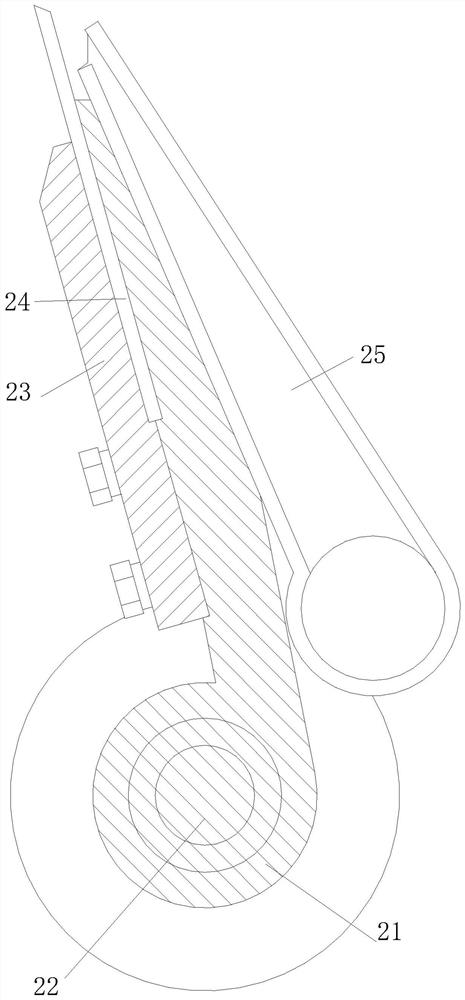

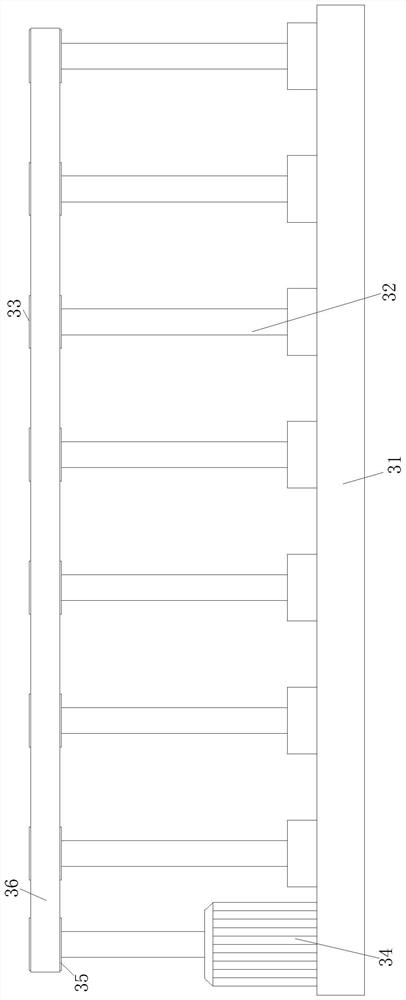

[0025] A kind of ceramic creping scraper assembly for paper production provided by the present invention based on the above-mentioned purpose, such as figure 1 and Figure 4 As shown, it includes a frame 1, a scraper frame 2 rotatably mounted on the frame 1, a grinding assembly 3 mounted on the frame 1, a drive assembly 4 connected to the scraper frame 2 in transmission, Specifically, a ceramic wrinkling scraper 5 is installed in the scraper frame 2, and the driving assembly 4 drives the scraper frame 2 to rotate, so that the scraper frame 2 has at least a working station and a grinding station. 2 When it is at the working station, the ceramic creping scraper 5 cooperates with the drying cylinder 6 to realize the creping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com