A ladle cleaning agent and its preparation method and use method

A slag cleaning agent and slag agent technology, applied in the field of iron and steel metallurgy, can solve the problems of reducing the limited capacity of the ladle, residual, and the ladle slag is not easy to adhere to the ladle wall, so as to improve the service life and operation efficiency, prolong the online use time, The effect of shortening the cleaning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

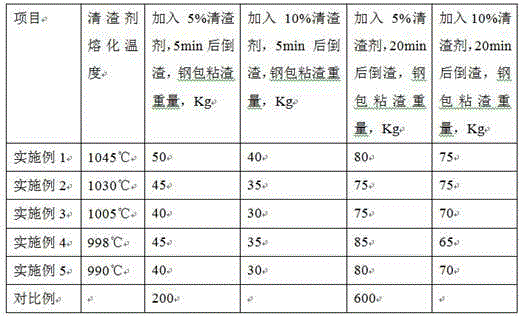

Embodiment 1

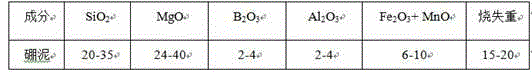

[0035] Adopt the poor manganese ore powder of Mn 10%, and batching composition is calculated as follows by mass percentage:

[0036] Manganese ore powder 40%, hematite powder 40%, boron mud 18%, glucose 2%.

[0037] Weigh the manganese ore powder, boron mud powder, and hematite powder, mix them according to the proportion, and then mix them on the roller mill. During the mixing process, add water with a mass fraction of 5% of the solid material by spraying to adjust the humidity , after the glucose powder is dissolved in water to make a 50% solution, it is added during the humidity control process; then, it is pressed into balls by a ball press machine, the particle size of the balls is 4-5cm, and the balls are dried at 200°C for 4 hours, Then after cooling, the finished product is packaged.

Embodiment 2

[0039] Adopt the manganese ore powder of Mn 20%, batching composition is calculated as follows by mass percentage:

[0040] Manganese ore powder 45%, hematite powder 35%, boron mud 18%, glucose 2%.

[0041] Weigh the manganese ore powder, boron mud powder, and hematite powder, mix them according to the proportion, and then mix them evenly on the roller mill. During the mixing process, add water with a mass fraction of 6% of the solid material by spraying to adjust the humidity , after the glucose powder is dissolved in water to make a 50% solution, it is added during the humidity control process; then, it is pressed into balls by a ball press machine, the particle size of the balls is 4-5cm, and the balls are dried at 200°C for 4.5 hours , and then packaged after cooling to obtain a finished product.

Embodiment 3

[0043] Adopt the manganese ore powder of Mn 25%, batching composition is calculated as follows by mass percentage:

[0044] Manganese ore powder 50%, hematite powder 30%, boron mud 18%, glucose 2%.

[0045] Weigh the manganese ore powder, boron mud powder, and hematite powder, mix them according to the proportion, and then mix them on the roller mill. During the mixing process, add water with a mass fraction of 5.5% of the solid material by spraying to adjust the humidity , after the glucose powder is dissolved in water to make a 50% solution, it is added during the humidity control process; then, it is pressed into balls by a ball press machine, the particle size of the balls is 4-5cm, and the balls are dried at 200°C for 4.5 hours , and then packaged after cooling to obtain a finished product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com