A side guide roller for super wear-resistant hot-rolled strip production line

A hot-rolled sheet and side guide roller technology is applied in the field of side support and guide mechanism on a hot-rolled sheet and strip production line, and can solve the problems of inability to completely eliminate the scallops, increase the operation and maintenance costs, and reduce the yield of the sheet and strip, etc. To achieve the effect of reducing the cost of spare parts procurement and operation and maintenance, improving the possibility of repair and remanufacturing, and improving the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

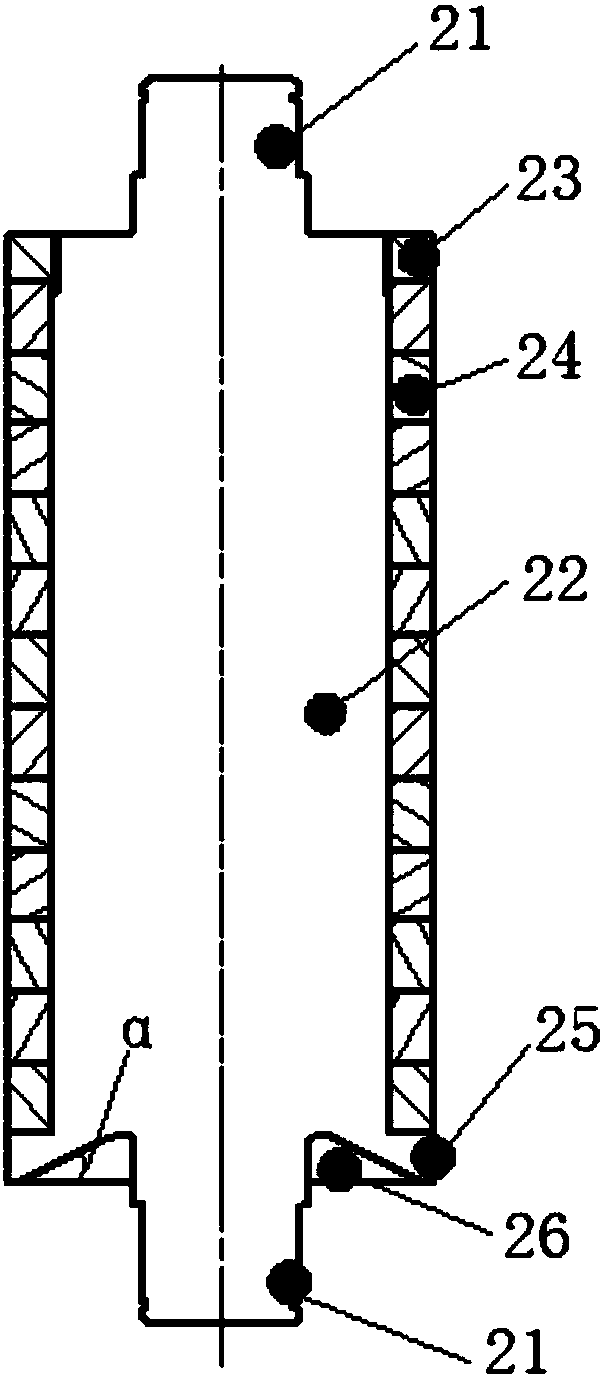

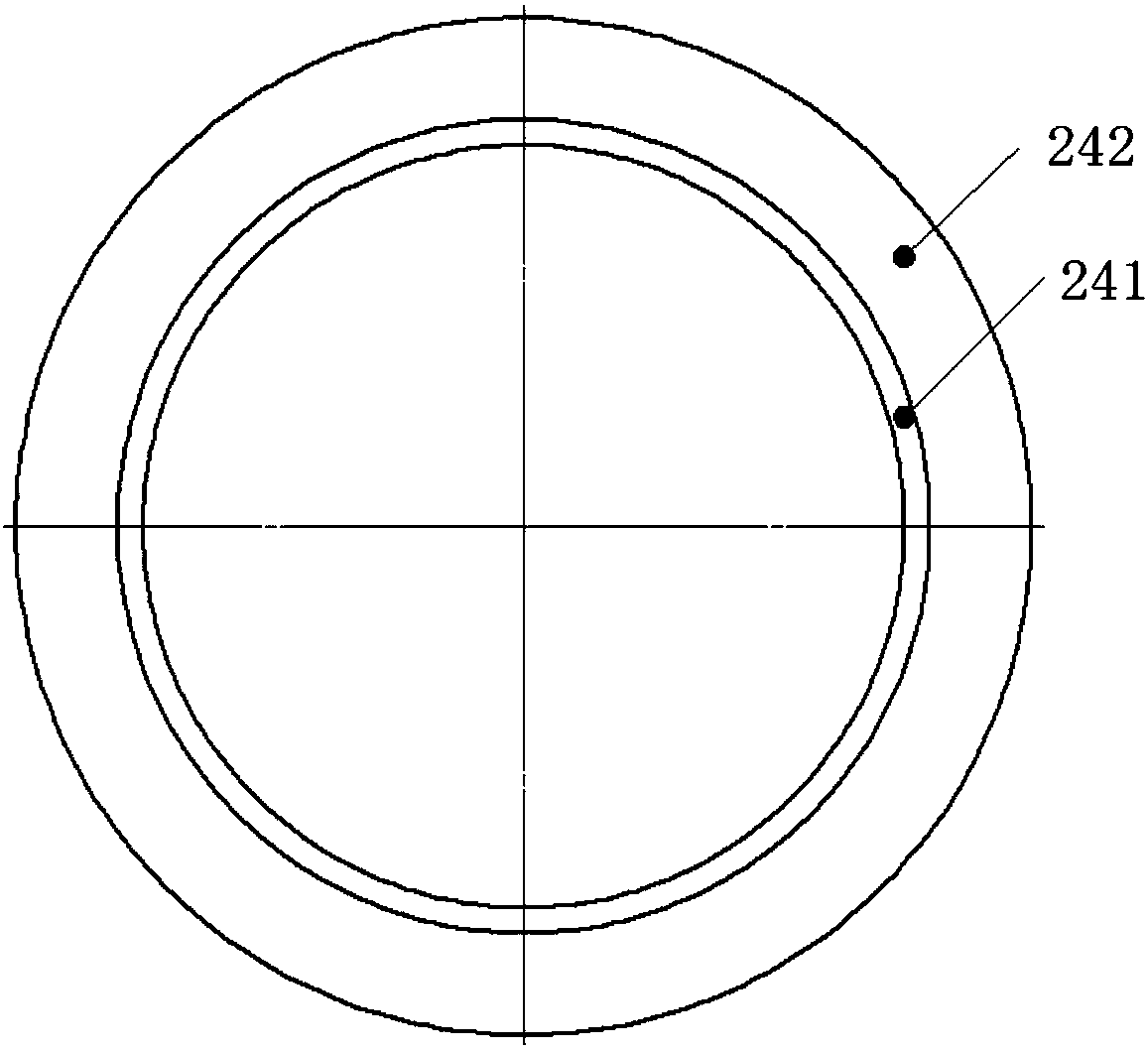

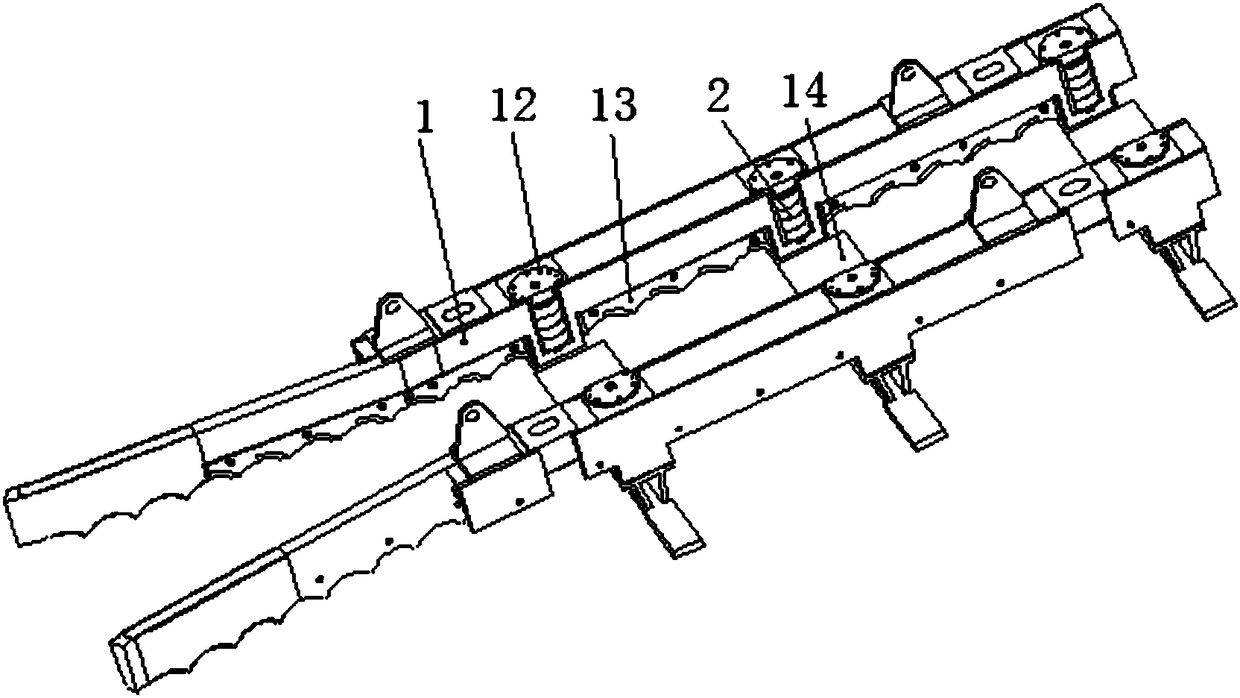

[0021] Such as Figure 1~3 As shown, the side guide body 1 of the present embodiment includes two side guide body bodies 1 oppositely arranged, and each side guide body body 1 has three side guide rollers 2. The transmission channel for hot-rolled plate transmission, the corresponding clamping opening 11 is opened on the side guide body 1, and the clamping opening 11 is arranged along the height direction of the side guide body 1, and the side guide roller 2 is clamped on In the clamping port 11, the cross section of the clamping port 11 is an arc, the top and the bottom of the clamping port 11 are respectively pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com