Flour suitable for being eaten by children and production method of flour

A production method and technology of flour, applied to the functions, applications, and food sciences of food ingredients, etc., can solve the problems of few types of nutrients, achieve the effects of increasing the content of nutrients, reducing strength, and improving taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

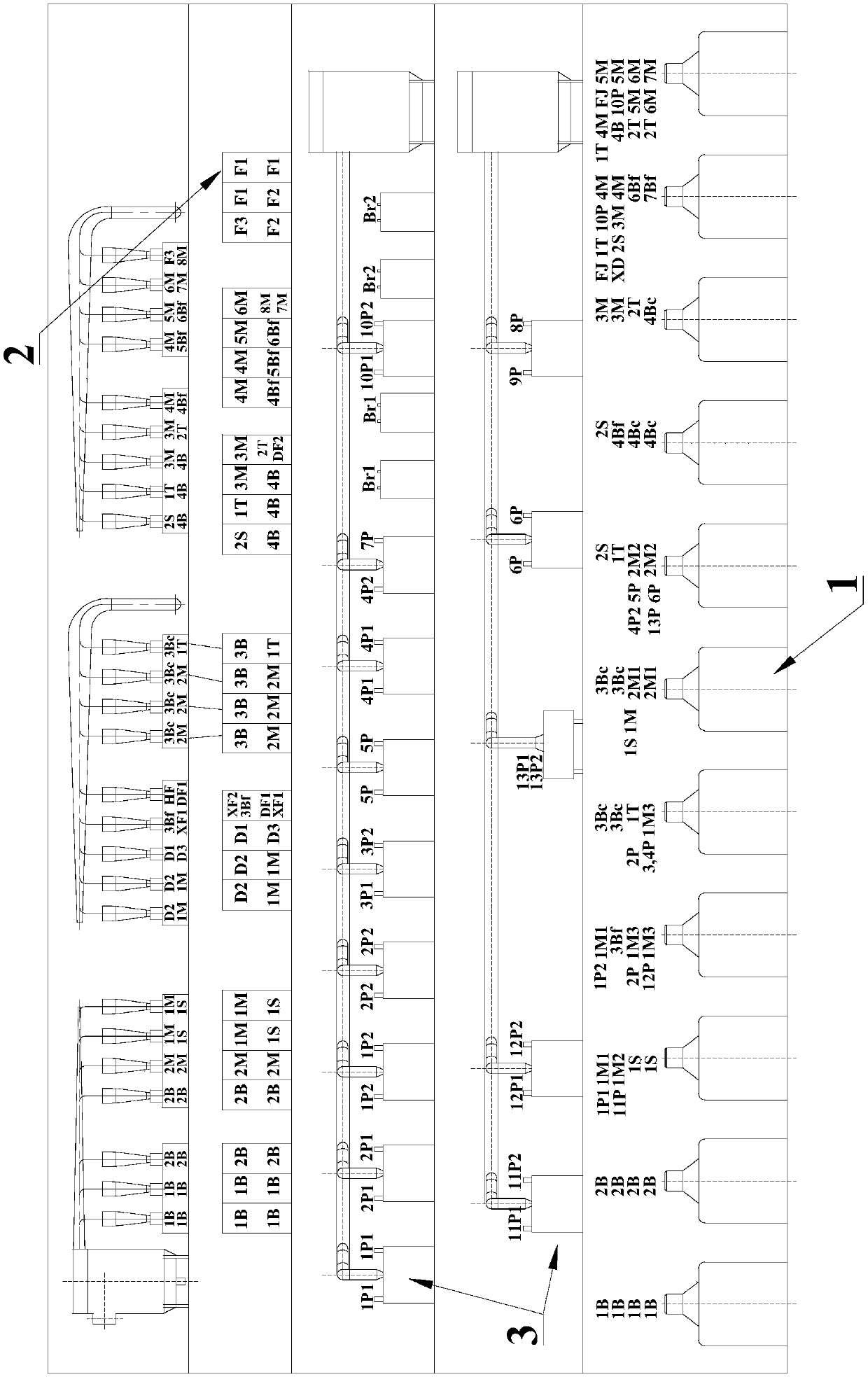

[0029] like figure 1 Shown, a kind of production method of the flour that is suitable for children, comprises the following steps:

[0030] 1) Take the clean wheat and put it into the grinder 1 for skin grinding. After grinding, the material is divided into bran, coarse material, heart material and powder after screening;

[0031] 2) The bran obtained in step 1) is repeatedly subjected to the skin milling process of step 1), and the final obtained material is divided into tailings, coarse material, heart material and powder after screening;

[0032] 3) The coarse materials obtained in steps 1) and 2) are respectively re-entered into the grinder 1 for slag grinding, and the materials after the slag grinding are screened to obtain coarse materials, heart materials and powder respectively;

[0033] 4) The coarse material obtained in step 3) is repeatedly subjected to the slag grinding process of step 3), and the final material is screened to obtain tailings, heart material and p...

Embodiment 2

[0043] The difference between this embodiment and embodiment 1 is that the water content of the net wheat used in the step 1) is 15%, and the types and contents of each nutritional component contained in every 100g of flour in the present embodiment are as follows:

[0044] Yam powder: 1g, potato powder: 5g, spinach powder: 10g, almond powder: 3g, protein: 12g, vitamin A: 0.6mg, vitamin B: 0.6mg, vitamin C: 12mg, vitamin E: 1mg.

Embodiment 3

[0046] The difference between this embodiment and embodiment 1 is that the water content of the net wheat used in the step 1) is 18%, and the types and contents of each nutrient component contained in every 100g flour in the present embodiment are as follows:

[0047] Yam powder: 5g, potato powder: 15g, spinach powder: 20g, almond powder: 10g, protein: 15g, vitamin A: 1mg, vitamin B: 1.2mg, vitamin C: 18mg, vitamin E: 3mg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com