Die-casting die structure

A die-casting mold and mold core technology, which is applied in the field of mold structure, can solve problems such as poor filling of column positions, improve the life of ejector pins and product quality, prevent ejector pins from bending or breaking, and improve quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] A preferred embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings. However, the scope of protection of the present invention is not limited to the following examples, that is, any simple equivalent changes and modifications made based on the patent scope of the present invention and the content of the description are still within the scope of the patent of the present invention.

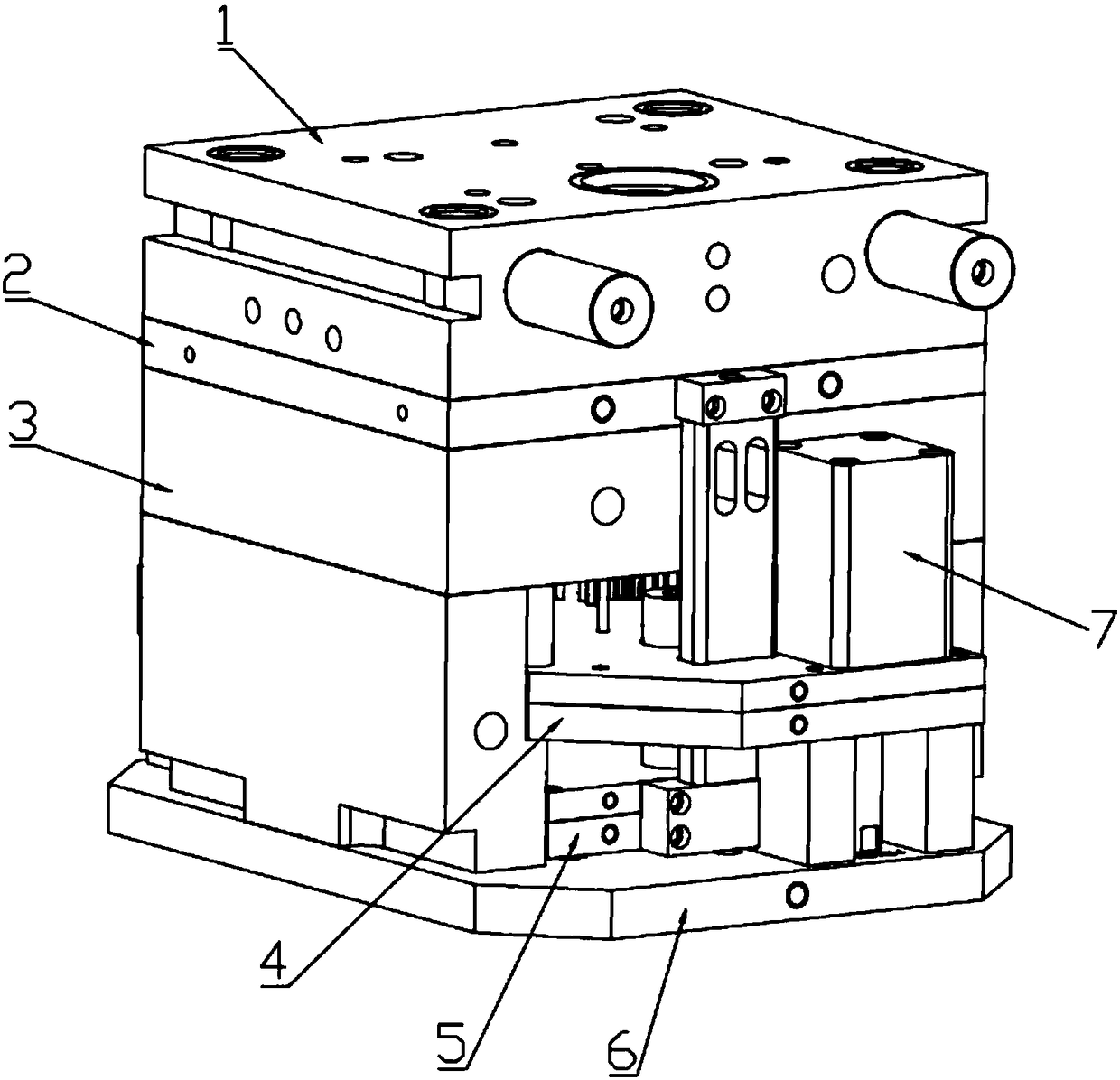

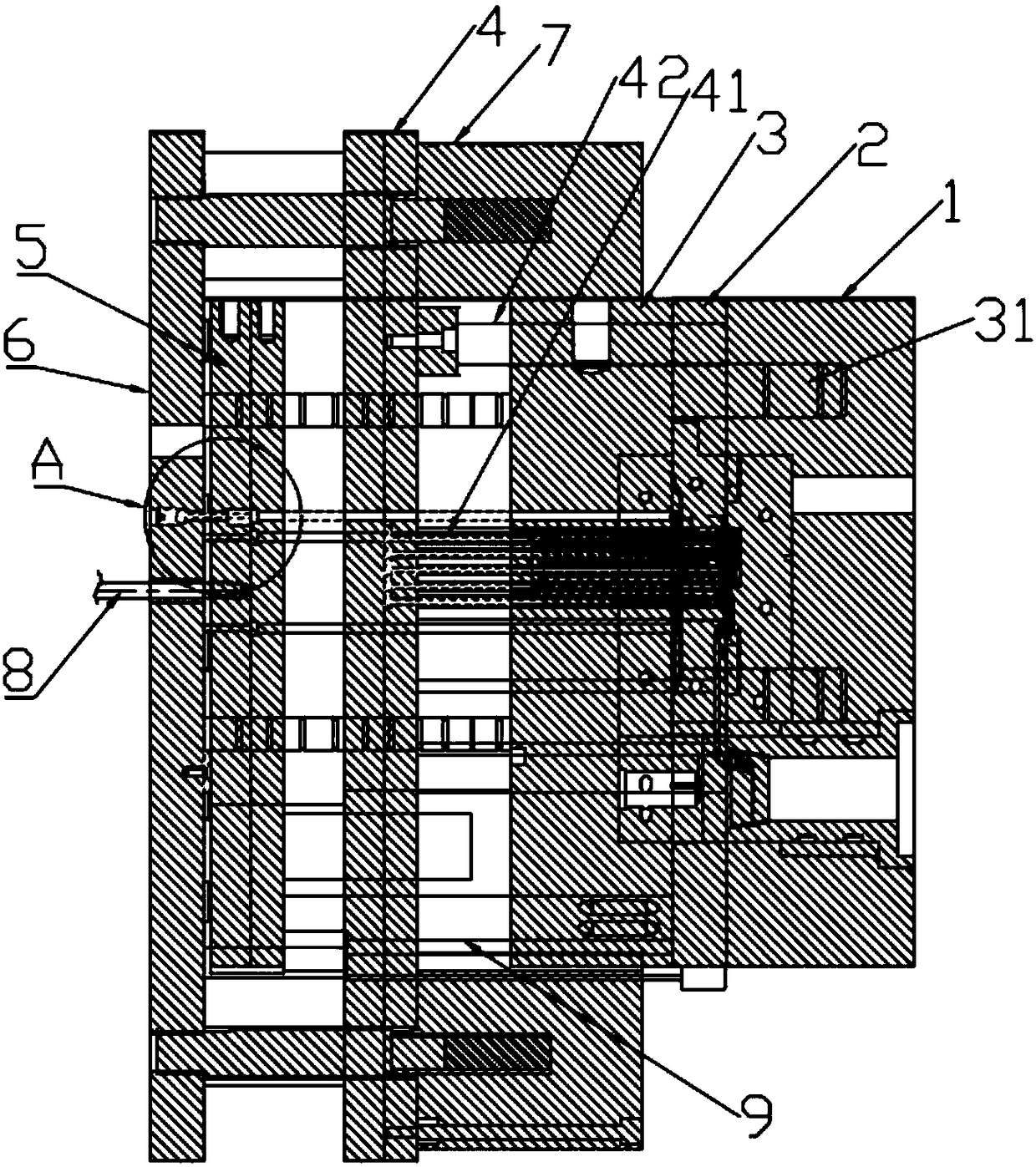

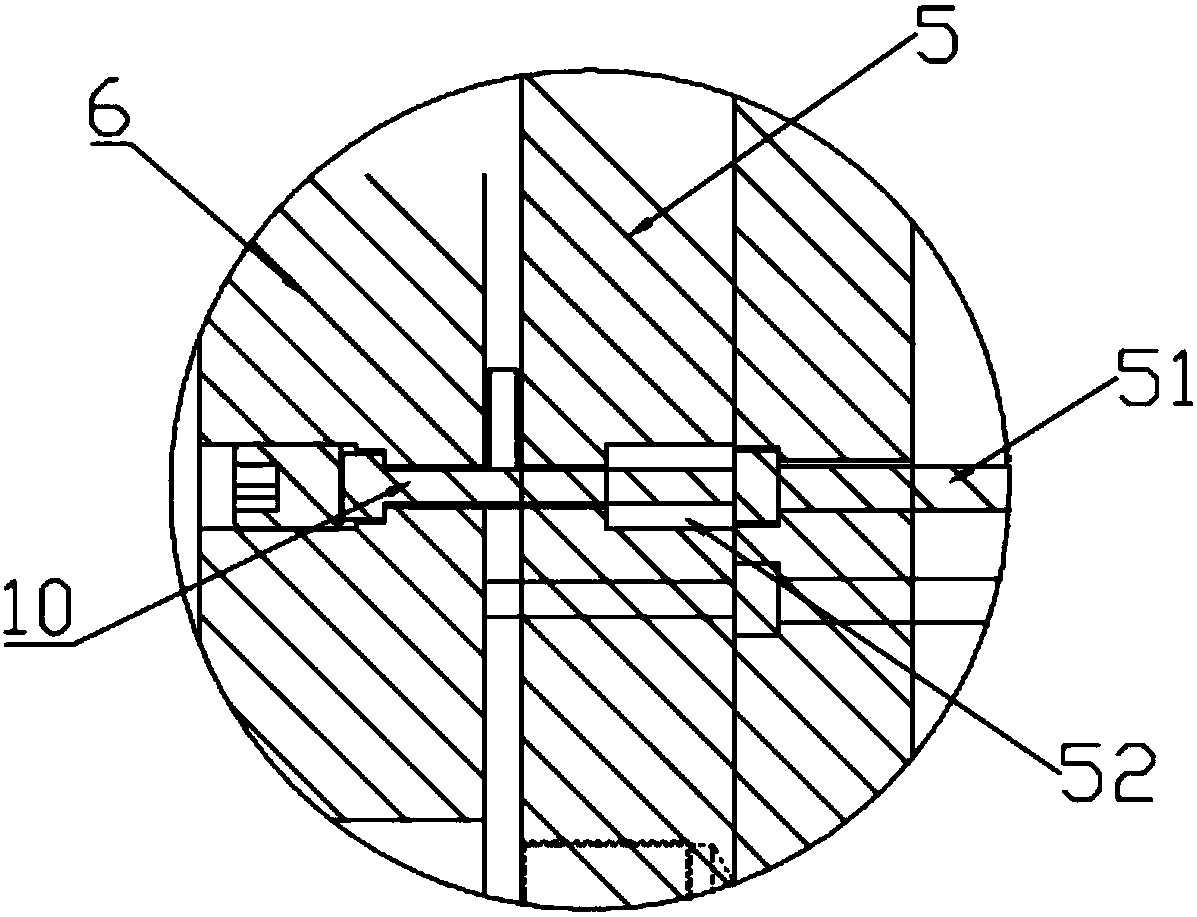

[0031] refer to Figure 1-11 , is a die-casting mold structure according to the present invention, including a front template 1, a first rear template 2, a second rear template 3, a first ejector plate 4, a second ejector plate 5 and a bottom plate 6 arranged in sequence, the A first mold core for forming products is provided between the front template and the first rear template, and a second mold core for slag discharge is provided between the first rear template and the second rear template; the first ejector plate A first thimb...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap