Integral forming method for large aluminum alloy welding plate sealing head with uniform performance

An integral forming, aluminum alloy technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of uneven distribution of wall thickness and mechanical properties, and achieve improved mechanical properties, uniform wall thickness, and uniform mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

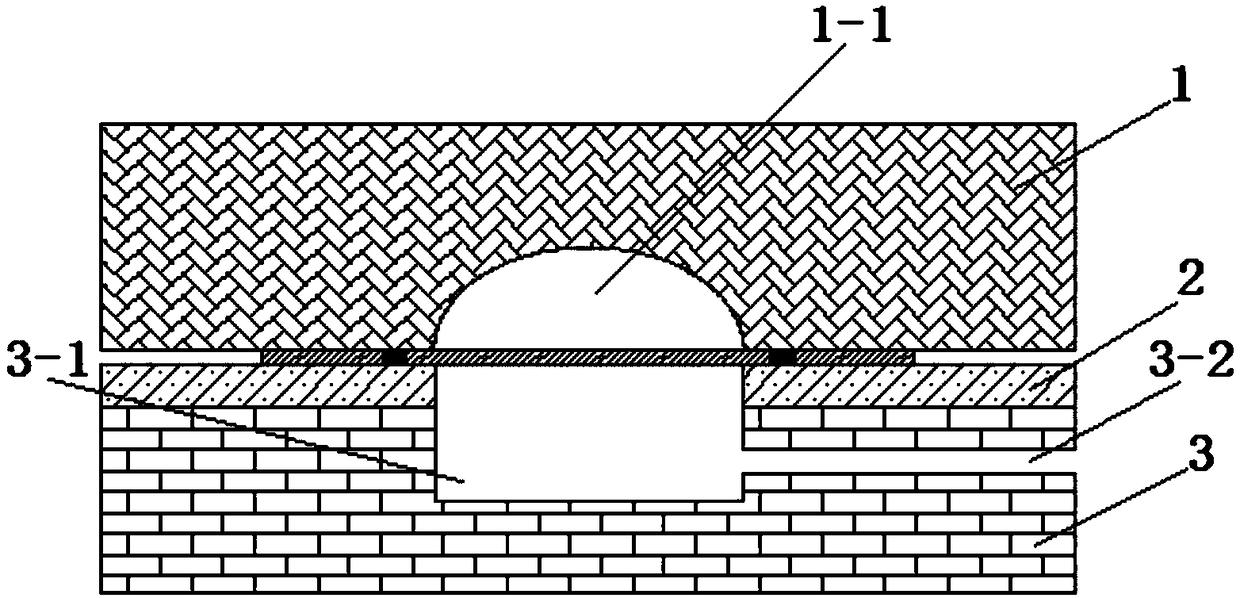

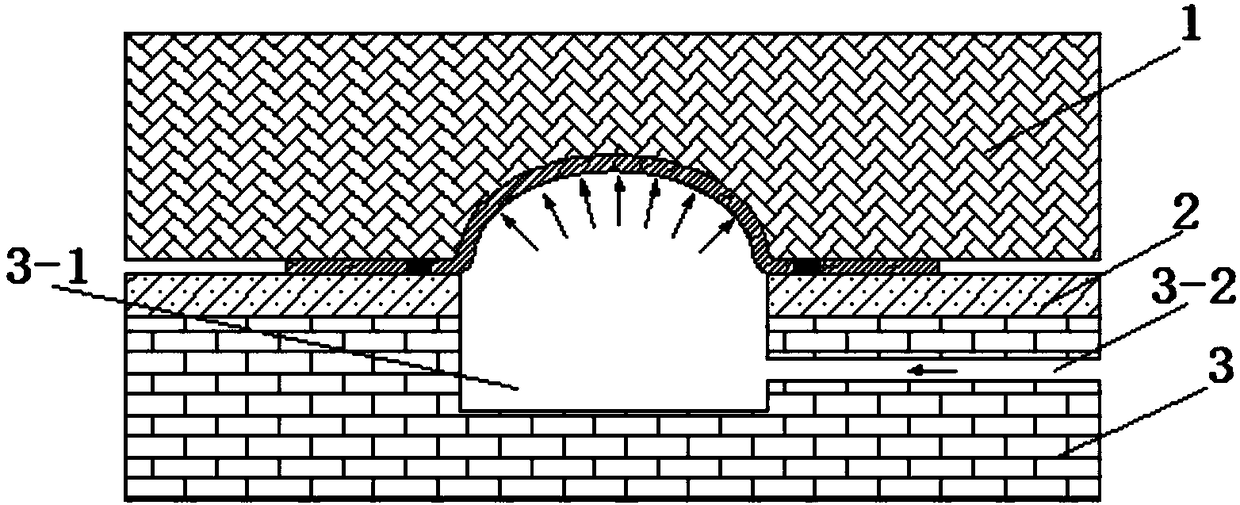

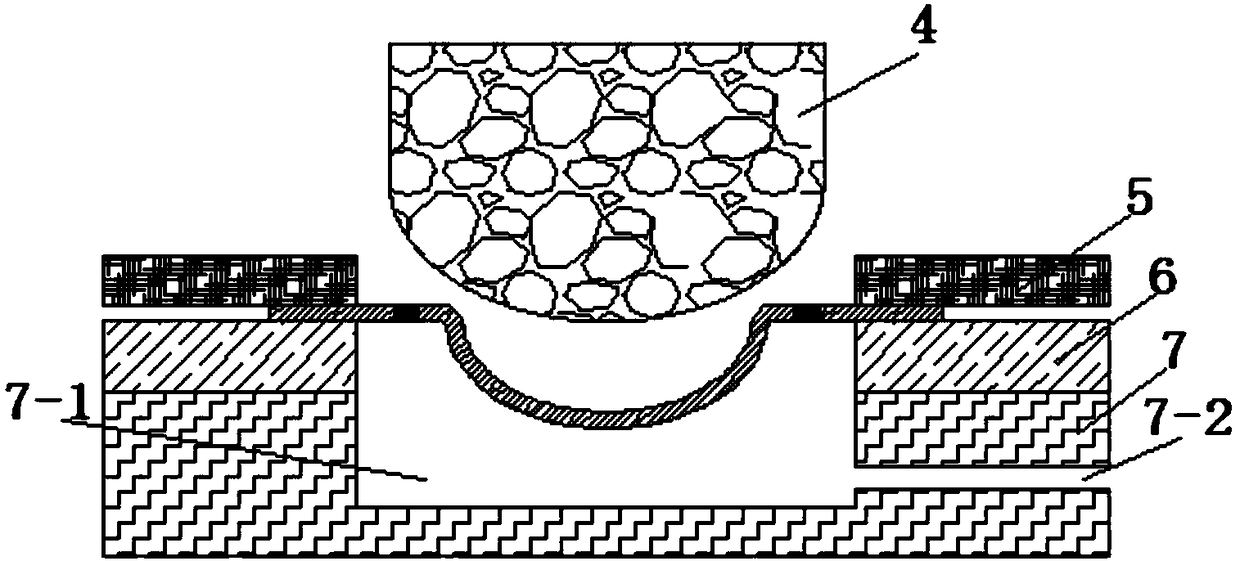

[0020] Specific implementation mode one: combine Figures 1 to 4 , this embodiment is a method for integrally forming a large-scale aluminum alloy tailored welded blank head with uniform performance, which is completed according to the following steps:

[0021] 1. Friction stir welding: Large-scale aluminum alloy tailor welded blanks are prepared by adopting the friction stir welding method with a welding advance speed of 200 mm / min to 400 mm / min and a rotation speed of 800 rpm to 1000 rpm, and the width of the large aluminum alloy tailor welded blanks is ≥ 4000 mm ;

[0022] 2. Partial bulging: Local bulging of large aluminum alloy tailor-welded blanks is carried out by using a local pre-expansion mold, which includes a local bulging die 1, a pre-expansion die 2, and a liquid-filled chamber 3. 3 is provided with a cylindrical inner cavity 3-1, and the cylindrical inner cavity 3-1 of the liquid-filled chamber 3 communicates with the liquid medium cavity of the hydraulic syste...

specific Embodiment approach 2

[0026] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that in step 2, the inner diameter of the end of the large-scale aluminum alloy tailor welded blank head is set to be A, and the distance between adjacent welds on the large aluminum alloy tailor-welded blank is For B, when A-B>2500mm, two auxiliary cavities are stacked on both sides of the dome-shaped cavity 1-1 of the partial bulging mold 1, and the distance between the outer edges of the two auxiliary cavities is H≤Large aluminum alloy tailored welded blank The inner diameter of the end of the head is A, and the width of the weld platform between the dome-shaped cavity 1-1 and the auxiliary cavity is h, and the weld width of the large aluminum alloy tailored welded blank is b, then h≥2b; the large The aluminum alloy tailor welded blank is placed between the local bulging die 1 and the pre-expansion die 2 of the partial pre-expansion mold, and the weld of the large aluminum alloy...

specific Embodiment approach 3

[0027] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: in step 1, a large-scale aluminum alloy tailor welded blank is prepared by adopting a friction stir welding method with a welding advance speed of 200 mm / min and a rotation speed of 800 rpm. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com