Gas rail of fuel gas ejector

A gas injector and gas rail technology, which is applied in the field of auto parts, can solve the problem of complex gas injector gas rail structure and processing technology, unreliable combination of intake pipe and external flexible gas pipe, and small cross-section of gas injector gas rail inner cavity and other problems, to achieve the effect of high welding one-time pass rate, improve reliability and stability, and save installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

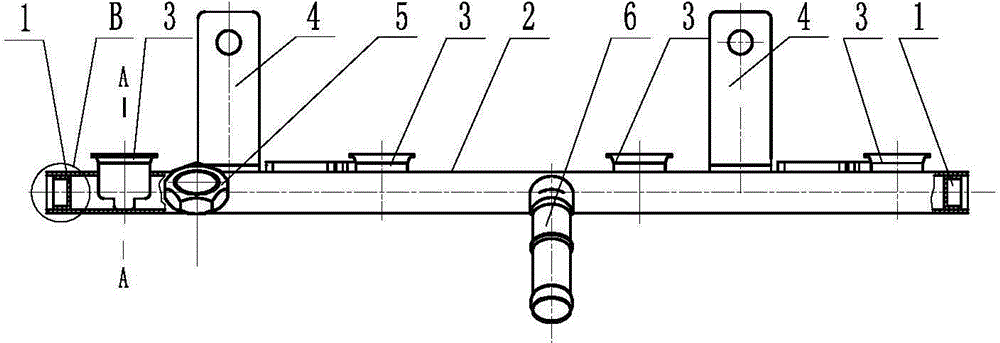

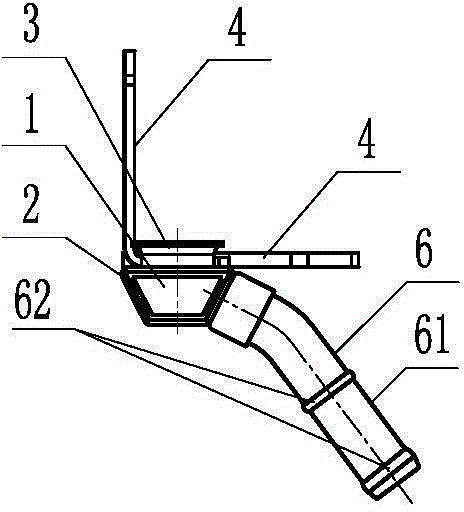

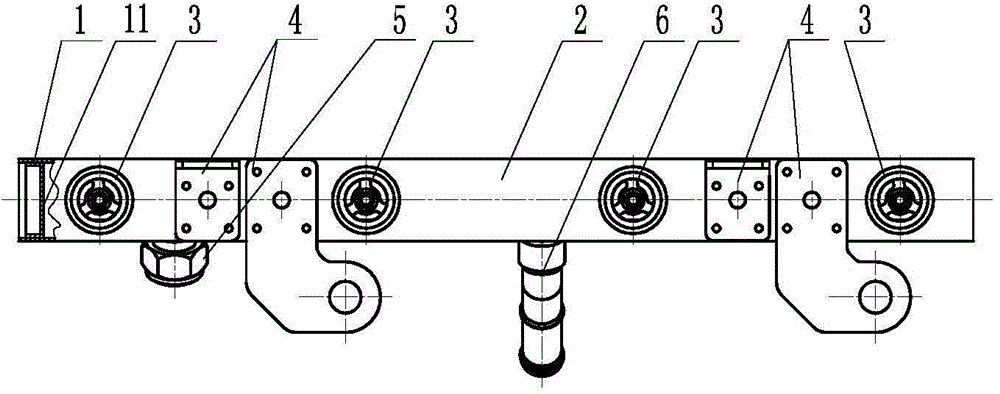

[0026] A gas injector rail, comprising a main air pipe 2, left and right end caps 1, a bracket 4 connected to the main air pipe, an air intake pipe 6, a sensor seat 5 and four uniformly distributed air nozzle seats 3, the left 1. The right end cover 1 is installed at both ends of the main air pipe, the air intake pipe is connected to the external hose, and the gas nozzle seat is connected to the external gas injector; the gas nozzle seat 3 is a cup-shaped structure, and there is a downward protrusion in the middle of the bottom of the cup There are three arc holes 32 evenly distributed on the circular surface at the bottom of the cup; the main air pipe 2 is a stainless steel square pipe, and its cross-sectional shape is an inverted trapezoid with a large upper part and a smaller lower part. There are four valve seat installation holes evenly distributed on the top surface, and the valve seat 3 is welded and fixed in the valve seat installation hole by sinking installation metho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com