PVC pipe and machining method thereof

A technology of PVC pipes and processing methods, applied in tubular articles, other household appliances, applications, etc., can solve the problems of inability to withstand heavy pressure, anti-aging, flammable and fragile, etc., to avoid scratches, high strength and Corrosion resistance, good cohesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

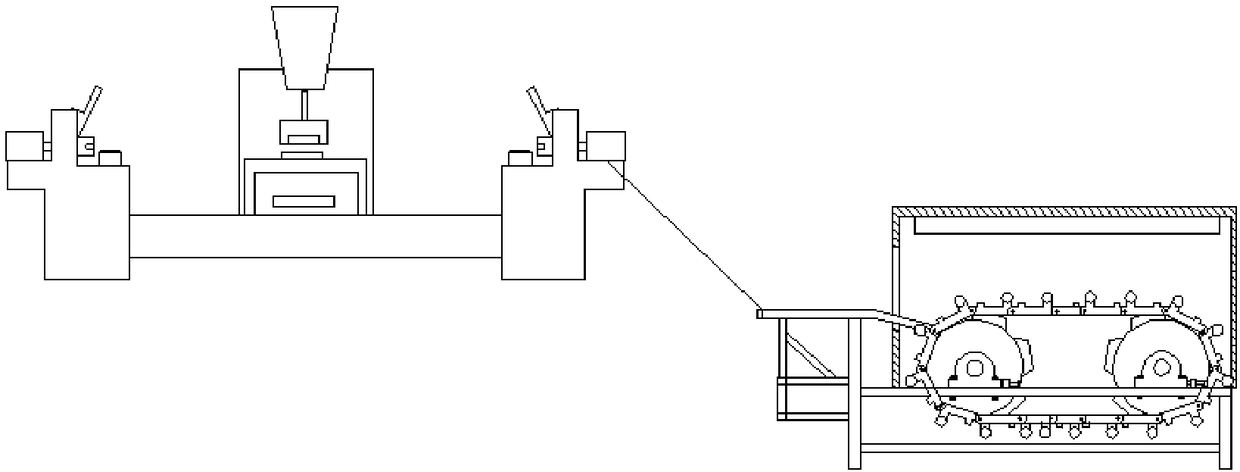

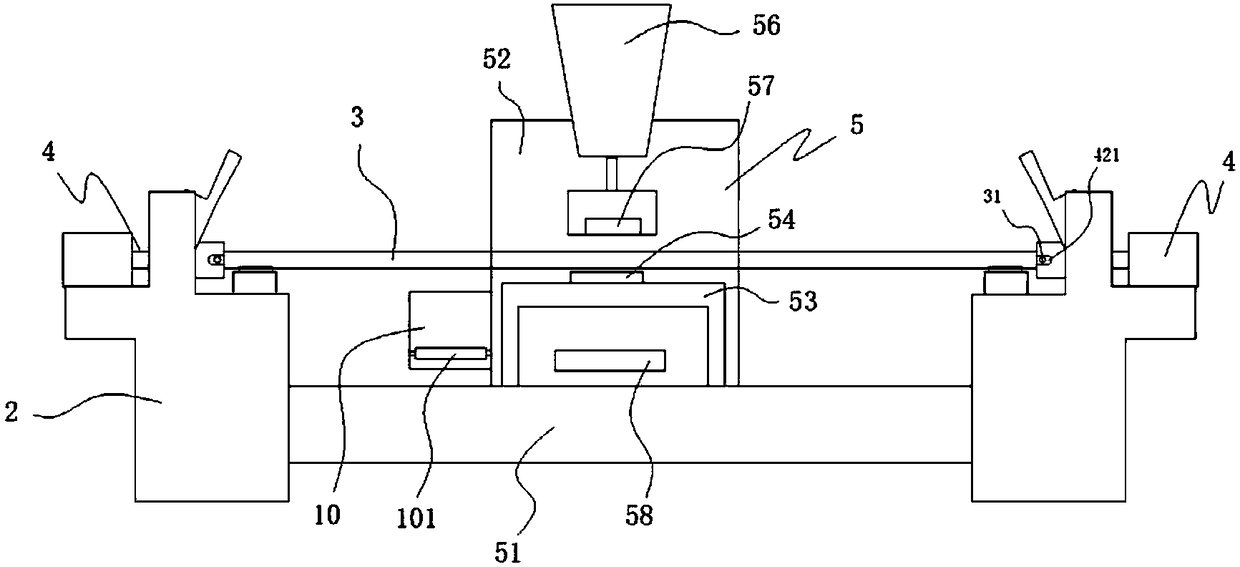

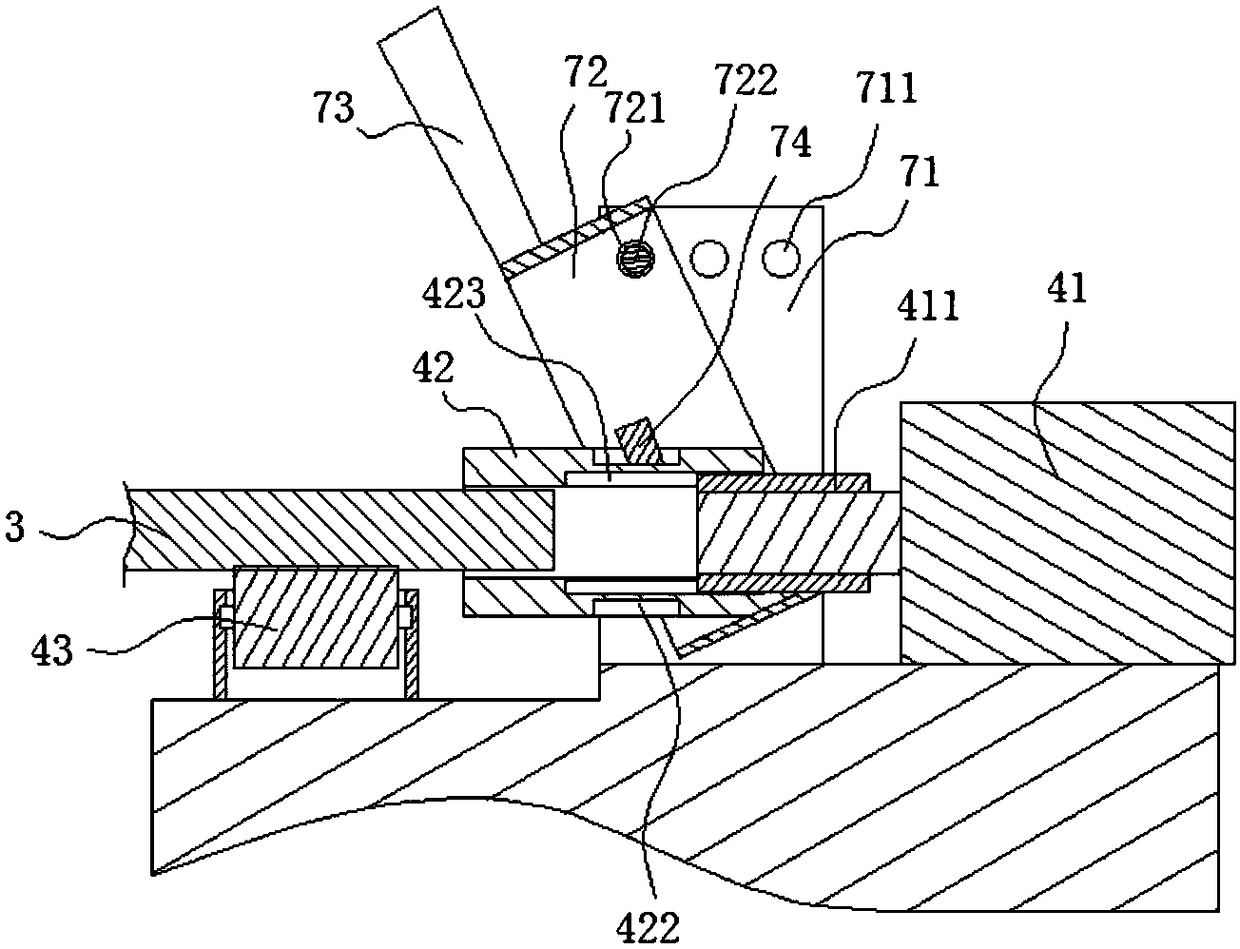

Image

Examples

Example Embodiment

[0032] Example 1

[0033] A PVC pipe material, including the following components in parts by weight: 20 parts of PVC resin, 15 parts of chlorinated polyethylene, 10 parts of ethylene propylene rubber, 10 parts of clay, 6 parts of stabilizer, 3 parts of quartz sand, FRP 2 parts, activated carbon 2 parts; also includes the following components in parts by weight ratio: 5 parts of water reducing agent, 3 parts of titanium dioxide, 3 parts of bentonite, 2 parts of expansion agent, 2 parts of plasticizer; specifically, the stabilizer The agent is a mercapto ester alkyl group, and the water reducing agent, expansion agent, and plasticizer are all directly purchased on the market and belong to the prior art, so specific materials are not specified.

[0034] The above-mentioned PVC pipe and its processing method include the following steps: (1) Obtain raw materials: PVC resin 20 kg, chlorinated polyethylene 15 kg, binary ethylene propylene rubber 10 kg, clay 10 kg, stabilizer 6 kg, quartz...

Example Embodiment

[0044] Example 2

[0045] A PVC pipe, including the following components in parts by weight: 30 parts of PVC resin, 20 parts of chlorinated polyethylene, 15 parts of ethylene propylene rubber, 12 parts of pottery clay, 8 parts of stabilizer, 5 parts of quartz sand, FRP 3 parts, activated carbon 3 parts; also includes the following components in parts by weight ratio: 8 parts of water reducing agent, 5 parts of titanium dioxide, 5 parts of bentonite, 3 parts of expansion agent, 3 parts of plasticizer; specifically, the stabilizer The agent is a mercapto ester alkyl group, and the water reducing agent, expansion agent, and plasticizer are all directly purchased on the market and belong to the prior art, so specific materials are not specified.

[0046] The above-mentioned PVC pipe and its processing method include the following steps: (1) Obtain raw materials: 30 kg of PVC resin, 20 kg of chlorinated polyethylene, 15 kg of binary ethylene propylene rubber, 12 kg of clay, 8 kg of stab...

Example Embodiment

[0048] Example 3

[0049] A PVC pipe material, including the following components in parts by weight: 30 parts of PVC resin, 15 parts of chlorinated polyethylene, 10 parts of ethylene propylene rubber, 12 parts of pottery clay, 6 parts of stabilizer, 5 parts of quartz sand, and FRP 3 parts, activated carbon 3 parts; also includes the following components in parts by weight ratio: 5 parts of water reducing agent, 3 parts of titanium dioxide, 3 parts of bentonite, 2 parts of expansion agent, 3 parts of plasticizer; specifically, the stabilizer The agent is a mercapto ester alkyl group, and the water reducing agent, expansion agent, and plasticizer are all directly purchased on the market and belong to the prior art, so specific materials are not specified.

[0050] The above-mentioned PVC pipe and its processing method include the following steps: (1) Obtain raw materials: PVC resin 30 kg, chlorinated polyethylene 15 kg, binary ethylene propylene rubber 10 kg, clay 12 kg, stabilizer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com