Rapidly-demoulded polyurethane combined polyether and polyurethane foam, and preparation methods thereof

A combination of polyether and mold release technology, applied in the field of materials, can solve the problems of huge site and equipment investment, slow return on assets, etc., to achieve the effect of improving production capacity and profit margins, and low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

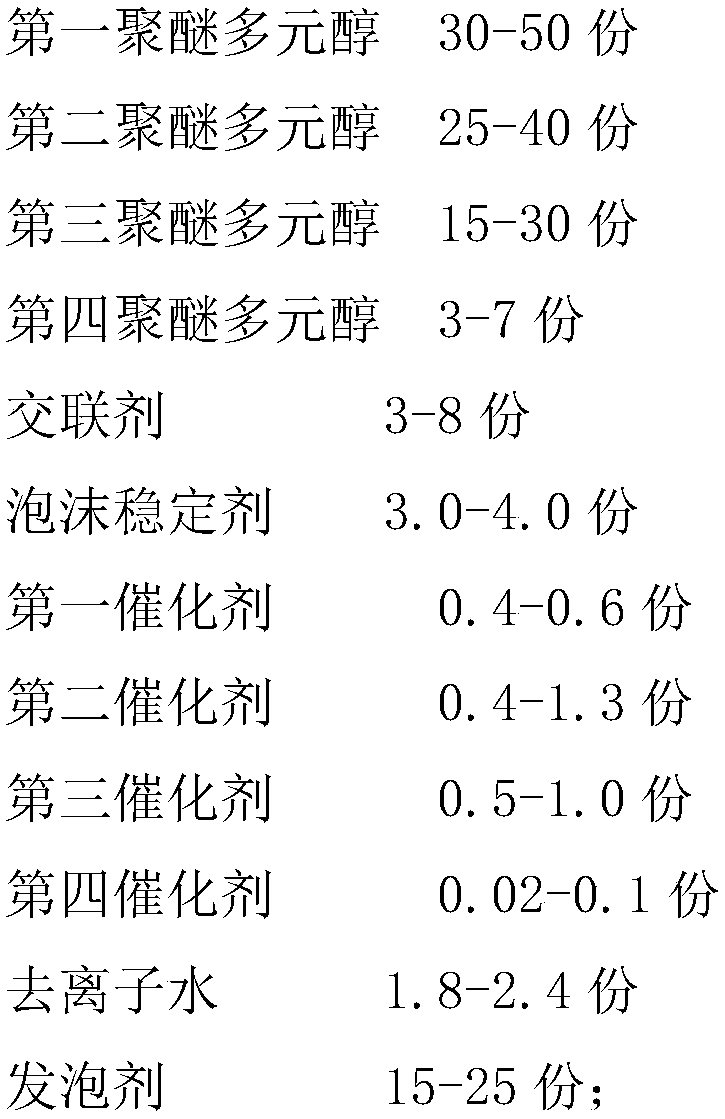

[0070] Prepare the first component according to the ingredients in the table below

[0071] raw material name

[0072] Pour the raw materials mentioned in the above table into the container according to the specified ratio, and mix them evenly with an electric mixer to make the first component; then pour the first component and the second component into the container according to the weight ratio of 1:1.2 , then use an electric mixer to stir for 6 seconds, pour the evenly mixed liquid into a mold with a thickness of 10cm at a constant temperature of 45-50°C, close the mold, place it at a constant temperature of 45°C for 150s, and then open the mold to get this Apply the quick release polyurethane foam.

Embodiment 2

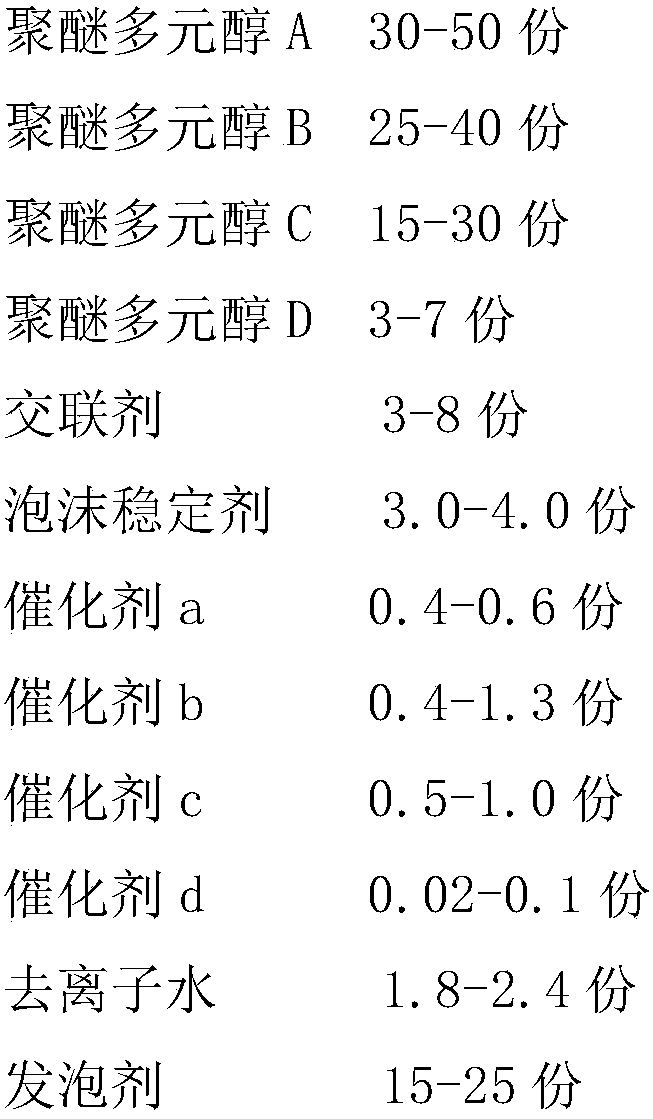

[0074] Prepare the first component according to the ingredients in the table below

[0075]

[0076]

[0077] Pour the raw materials mentioned in the above table into the container according to the specified ratio, and mix them evenly with an electric mixer to make the first component; then pour the first component and the second component into the container according to the weight ratio of 1:1.25 , then use an electric mixer to stir for 6 seconds, pour the evenly mixed liquid into a mold with a thickness of 10cm at a constant temperature of 45-50°C, close the mold, place it at a constant temperature of 45°C for 140s, and then open the mold to get this Apply the quick release polyurethane foam.

Embodiment 3

[0079] Prepare the first component according to the ingredients in the table below

[0080]

[0081]

[0082] Pour the raw materials mentioned in the above table into the container according to the specified ratio, and mix them evenly with an electric mixer to make the first component; then pour the first component and the second component into the container according to the weight ratio of 1:1.15 , then use an electric mixer to stir for 6 seconds, pour the evenly mixed liquid into a mold with a thickness of 10cm at a constant temperature of 45-50°C, close the mold, place it at a constant temperature of 45°C for 145s, and then open the mold to get this Apply the quick release polyurethane foam.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com