A kind of additive for foam cement

A technology of foamed cement and additives, applied in the field of foamed cement additives, can solve the problems of lower water absorption rate, slow demoulding, collapsed film, etc., and achieve the effects of promoting production efficiency, speeding up demoulding time, and reducing solidification time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

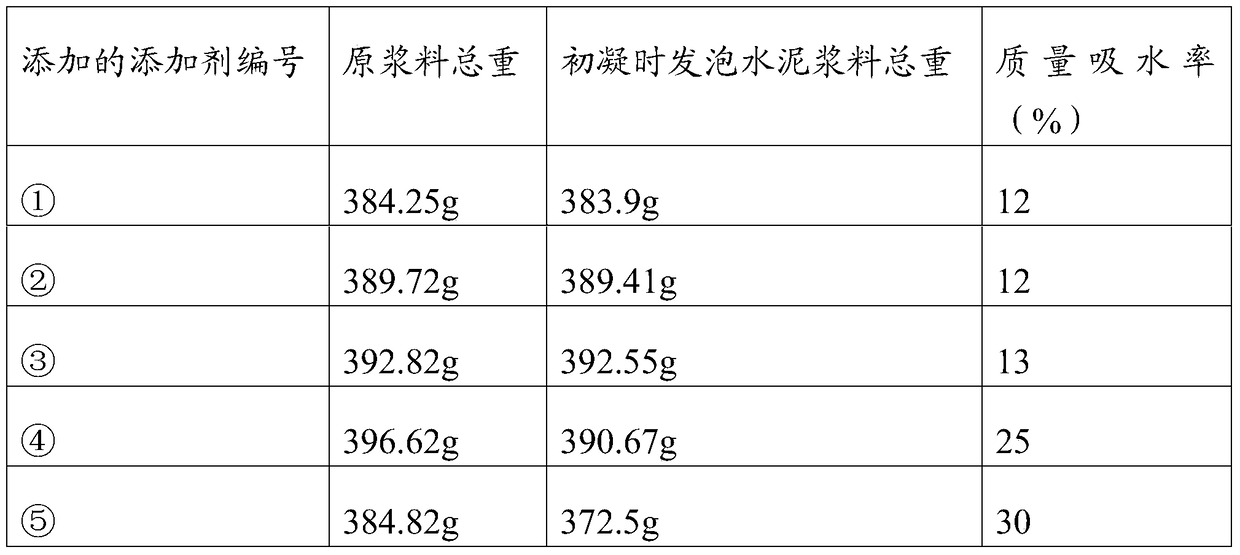

Examples

Embodiment 1

[0018] Preparation of Neem flower extract:

[0019] Weigh the neem flower and water according to the mass ratio of neem flower:water of 1:50 in g, put the neem flower and water into the autoclave to keep the temperature at 210°C, the pressure at 5MPa, and the stirring speed at 350r / min Supercritical extraction for 0.5h, after the temperature in the autoclave drops to 90°C or below, release the pressure and discharge the material, take out the material in the autoclave, keep the temperature at 47°C, heat and concentrate for 1h, and then put it in an oven for drying at 50°C After 30 minutes, it was ground into powder, ready for use. Heat 100g of kaolin to 600°C and keep it for 1 hour, and make metakaolin after cooling, which is ready for use.

[0020] Take g as the unit, weigh the required raw materials of each component: 0.8 g of ethyl acetate, 70 g of hydroxypropyl methylcellulose, 5 g of oleic acid, 5 g of silicone oil, 14 g of metakaolin prepared above, and rosin resin with...

Embodiment 2

[0022] Preparation of Neem flower extract:

[0023] Take the neem flower and water as the unit, weigh the neem flower and water according to the mass ratio of neem flower: water 1:30, put the neem flower and water into the autoclave to keep the temperature at 180°C, the pressure at 6MPa, and the stirring speed at 350r / min Supercritical extraction for 0.5h, after the temperature in the autoclave drops to 90°C or below, release the pressure and discharge the material, take out the material in the autoclave, keep the temperature at 40°C, heat and concentrate for 1h, and then put it in an oven for drying at 50°C After 30 minutes, it was ground into powder, ready for use. Heat 100g of kaolin to 500°C and keep it for 1 hour, and make metakaolin after cooling, which is ready for use.

[0024] Take g as the unit, weigh the required raw materials of each component: 0.2g of ethyl acetate, 20g of hydroxypropyl methylcellulose, 0.25g of oleic acid, 0.25g of silicone oil, 4g of metakaolin...

Embodiment 3

[0026] Preparation of Neem flower extract:

[0027] Take the neem flower and water as the unit, weigh the neem flower and water according to the mass ratio of neem flower:water 1:40, put the neem flower and water into the autoclave and keep the temperature at 240°C, the pressure at 4MPa, and the stirring speed at 350r / min Supercritical extraction for 1 hour, after the temperature in the autoclave drops to 90°C or below, release the pressure and discharge the material, take out the material in the autoclave, keep the temperature at 53°C, heat and concentrate for 1h, then put it in an oven for 30 minutes at 50°C , ground into powder, that is, ready for use. Heat 100g of kaolin to 700°C and keep it for 1 hour, and make metakaolin after cooling, which is ready for use.

[0028] Take g as the unit, weigh the required raw materials of each component: 0.5g of ethyl acetate, 45g of hydroxypropyl methylcellulose, 0.4g of oleic acid, 0.3g of silicone oil, 9g of metakaolin prepared abov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com