One-component silane-modified sealant for industrial buildings

A silane-modified and silane-modified polyether technology, which can be used in buildings, building structures, adhesives, etc., can solve problems such as hidden dangers of mechanical properties, and achieve the effect of improving and stabilizing performance and improving shear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

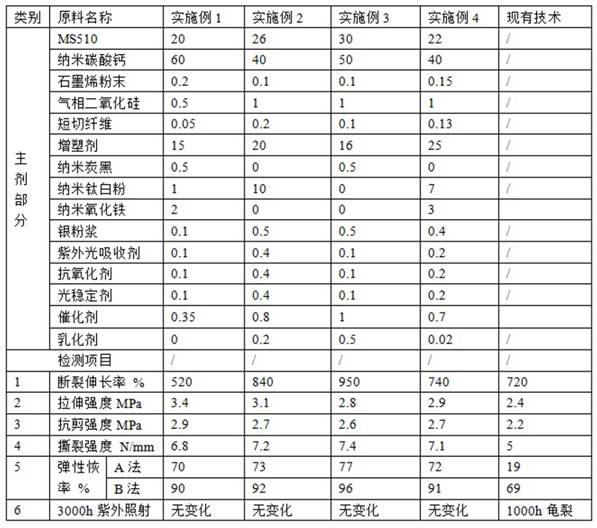

[0046] Table 1 summarizes the composition of each raw material in Examples 1-4 and the list of parts by weight, as well as the performance test data, and compares it with the prior art.

[0047] Table 1 Embodiment 1-4 formulation components and test data Component unit: part

[0048]

[0049] Weigh each material according to the components and proportions in Table 1, dry and dehydrate the solid material at 70-80°C for 1 hour under vacuum conditions, and cool it for later use;

[0050] Clean the inner wall of the mixing kettle and its stirring blades on the double planetary mixer, and dry it by self-heating and vacuuming, and fill the mixing kettle with dry nitrogen after cooling;

[0051] First add silane-modified polyether resin MS510 and plasticizer to the planetary mixer, then add nano-calcium carbonate, fumed silica, graphene powder, nano-pigment, ultraviolet light absorber, light stabilizer, antioxidant, material temperature Heat to 80°C and disperse at high speed at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com