A kind of preparation method of antibacterial material for papermaking

A technology of antibacterial materials and microspheres, applied in papermaking, textiles, papermaking, paper, etc., can solve problems such as not easy to contact the human body for a long time, environmental damage, etc., achieve a balanced sterilization effect, meet long-term storage, and have good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

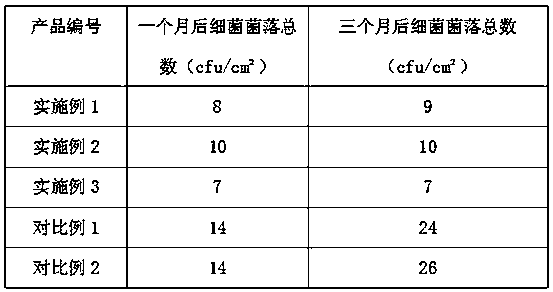

Examples

Embodiment 1

[0019] In the reaction kettle, add cellulose acetate microspheres 100Kg, carboxymethyl chitosan 32.5Kg, (4-carboxyphenylethynyl) trimethylsilane 2Kg, 5-bromo-4-chloro-3-indolyl -beta-d-xyloside 0.02Kg, tetrachlorobis(cyclohexylmercapto)titanium 0.7Kg, 1-butylsulfonic acid-3-methylimidazole trifluoromethanesulfonate ionic liquid 0.3Kg, p-toluenesulfonate 1Kg of acid and 150Kg of water, heated up to 90°C, reacted for 7.5 hours, filtered after the reaction, washed with water, and dried to obtain an antibacterial material for papermaking loaded with cellulose acetate microspheres.

Embodiment 2

[0021] In the reaction kettle, add 100Kg of cellulose acetate microspheres, 25Kg of carboxymethyl chitosan, 1Kg of (4-carboxyphenylethynyl) trimethylsilane, 5-bromo-4-chloro-3-indolyl- beta-d-xyloside 0.01Kg, tetrachlorobis(cyclohexylmercapto)titanium 0.5Kg, 1-butylsulfonic acid-3-methylimidazolium trifluoromethanesulfonate ionic liquid 0.1Kg, p-toluenesulfonic acid 1.5Kg, 100Kg of water, heating up to 85°C, reacting for 5 hours, after the reaction, filter, wash with water, and dry to obtain the antibacterial material for papermaking loaded with cellulose acetate microspheres.

Embodiment 3

[0023] In the reaction kettle, add cellulose acetate microspheres 100Kg, carboxymethyl chitosan 40Kg, (4-carboxyphenylethynyl) trimethylsilane 3Kg, 5-bromo-4-chloro-3-indolyl- beta-d-xyloside 0.1Kg, tetrachlorobis(cyclohexylmercapto)titanium 1Kg, 1-butylsulfonic acid-3-methylimidazolium trifluoromethanesulfonate ionic liquid 0.5Kg, p-toluenesulfonic acid 1.5 Kg, water 200Kg, heat up to 95°C, react for 10h, filter after the reaction, wash with water, and dry to obtain the antibacterial material for papermaking loaded with cellulose acetate microspheres.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com