Compensation rail in-situ lifting suspension monorail turnout system

A technology of suspending monorail and compensating rail, which is applied in the field of rail transit, can solve the problems of large and complex structure of turnout, and achieve the effect of reducing cost, simplifying driving device and reducing the weight of turnout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

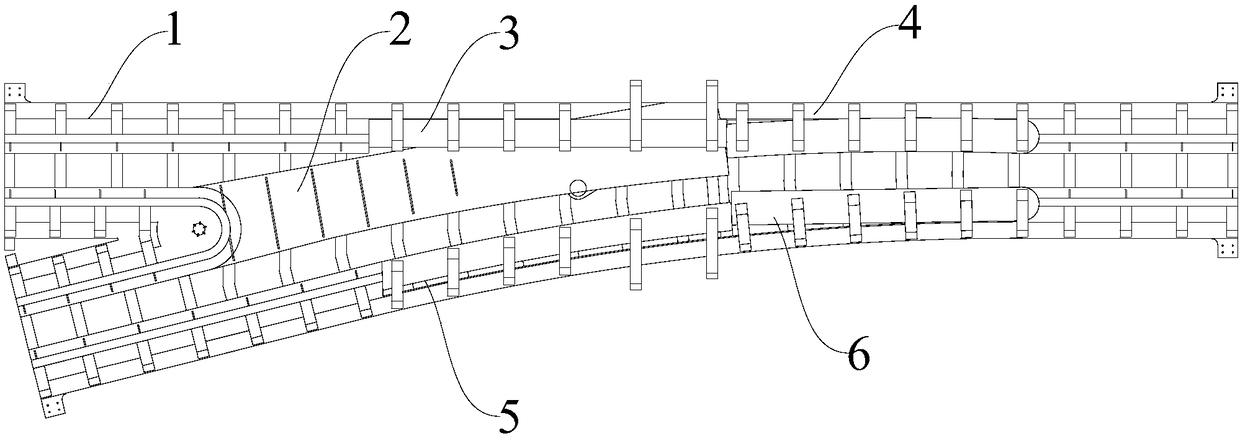

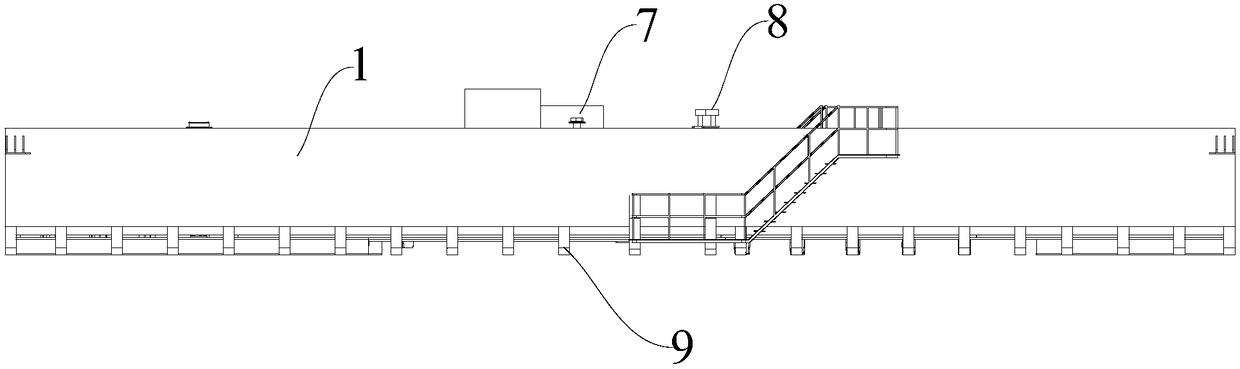

[0047] Such as Figure 1-Figure 2 As shown, a compensation rail in-situ lifting suspension single-track switch system includes a movable rail 2 connected to the turnout beam body 1, and a vertical compensation rail 3 and a lateral compensation rail 5 that can be raised and lowered in situ, and also includes The vertical correction rail 4 and the lateral correction rail 6 hinged on the turnout beam body 1, the movable rail 2 can be lifted and rotated left and right, and can be pressed and positioned after rotating to a specified position. The straight correction rail 4 and the lateral correction rail 6 can rotate respectively relative to the turnout beam body 1, and the straight correction rail 4 and the lateral correction rail 6 are rotated by a correction rail drive mechanism, and the correction rail The driving mechanism includes a correction rail electric push rod and a correction rail connection hinge.

[0048] The movable rail 2 is provided with a movable rail front end ...

Embodiment 2

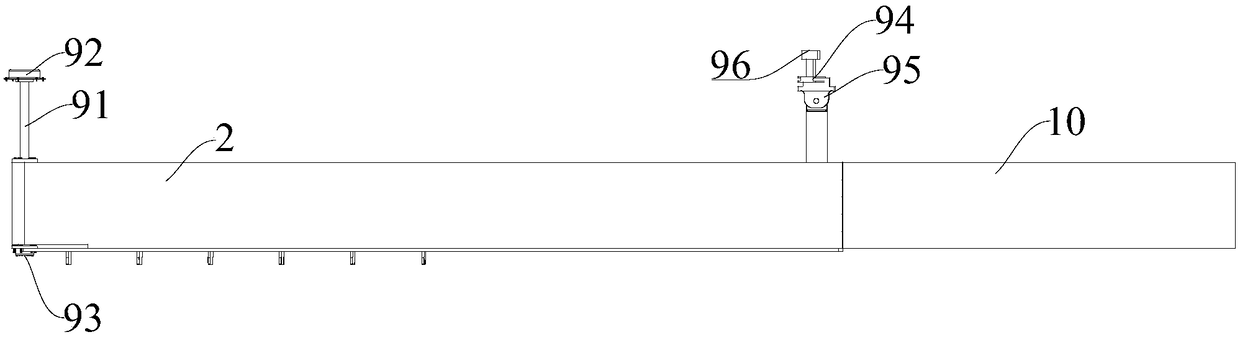

[0064] Such as Figure 10-Figure 13 As shown, the difference between this embodiment and Embodiment 1 is that a different compensation rail in-situ lifting mechanism is used. The compensation rail in-situ elevating mechanism 7 in this embodiment includes a lower base 710 , a crankshaft 711 and an upper connecting seat 712 , and the upper surface of the lower base 710 is provided with a groove 713 capable of accommodating the upper connecting seat 712 .

[0065] The upper connecting seat 712 is connected to the compensation rail, at least one crankshaft 711 is hinged between the lower base 710 and the upper connecting seat 712, and each crankshaft 711 includes two crank rods hinged to each other, The lower base 710 is provided with two types of stoppers 79 compatible with the crankshaft 711, the two types of stoppers 79 are respectively angled stoppers 791 and oblique stoppers 792, and one side of the compensation rail is also provided with There is a drive locking device 11 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com