Apparatus and method for measuring aluminium combustion of solid propellant based on coaxial digital holographic method

A solid propellant and digital holography technology, applied in measuring devices, instruments, particle size analysis, etc., can solve the problems of large measurement influence, difficulty in distinguishing combustion flame area and condensed phase particle area, and inability to clearly capture combustion particles, achieving Clearly Captured Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

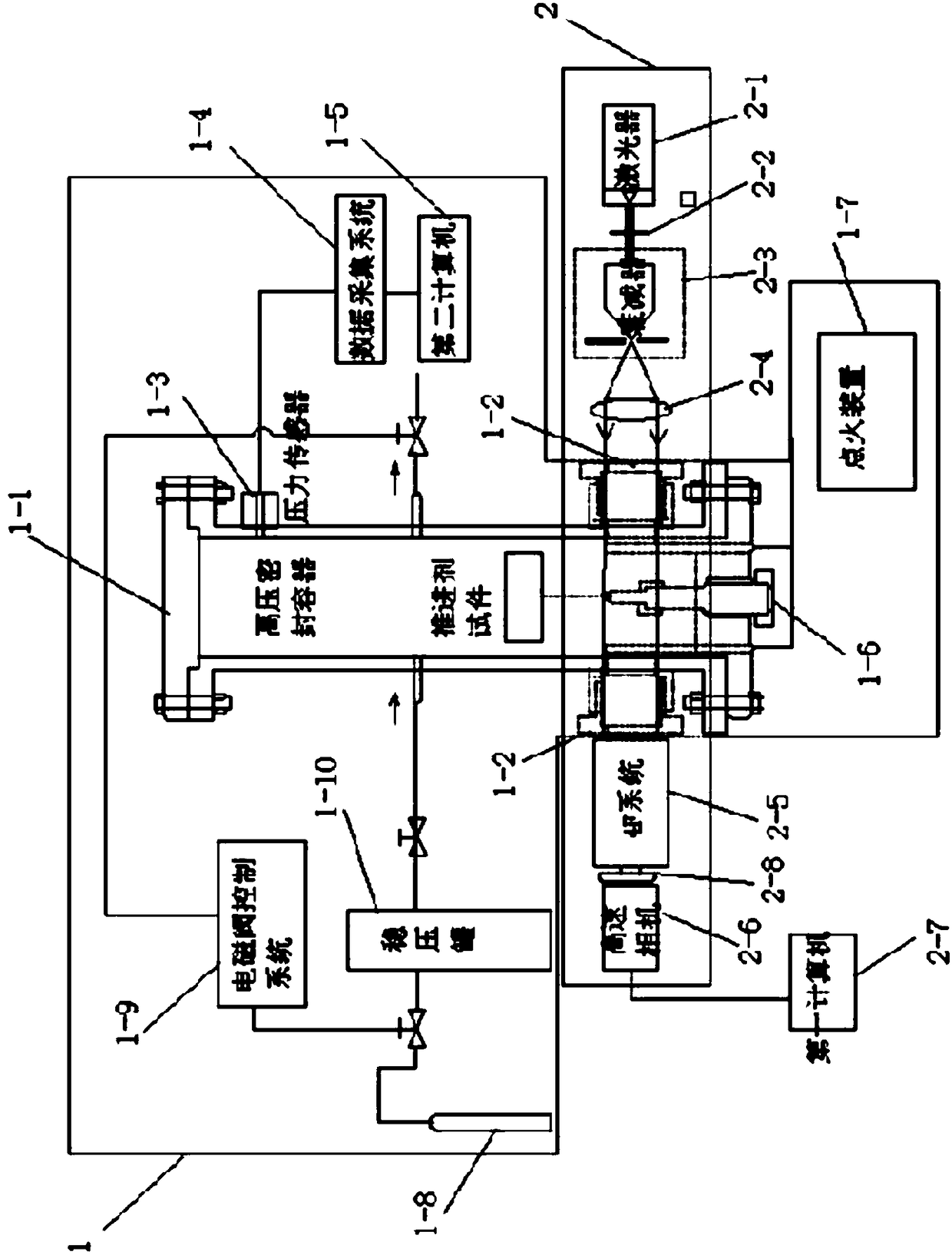

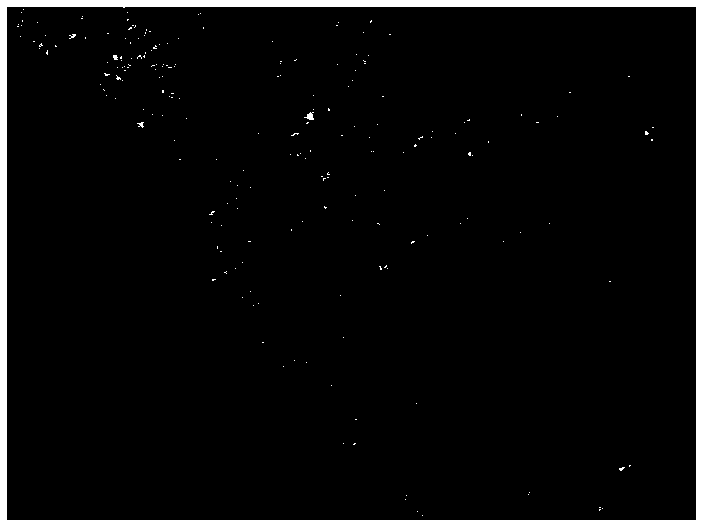

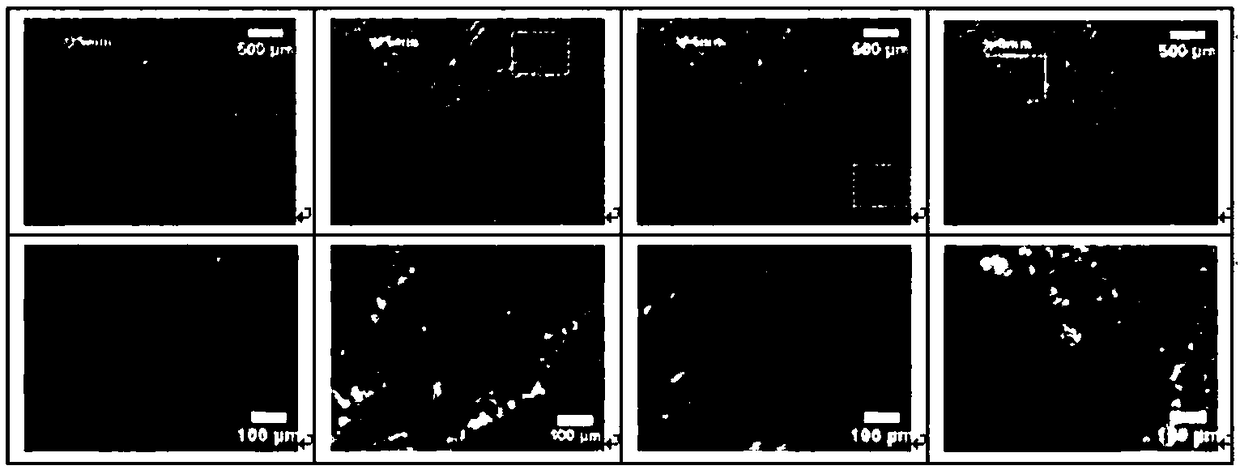

[0020] The solid propellant aluminum combustion measurement device and method based on the coaxial digital holography method of the present invention, as shown in Figure 1, includes a high-pressure sealed experimenter 1 for simulating the combustion of propellant in the combustion chamber of a solid rocket motor and a The digital holographic system 2 for measuring burning aluminum particles; the digital holographic system 2 is vertically intersected with the high-pressure sealed experimenter 1, and the planar coherent light of the digital holographic system 2 passes through the high-pressure sealed experimenter 1 to measure the propellant burning aluminum particles.

[0021] The high-pressure sealing experimenter 1 includes a high-pressure sealing container 1-1, and a group of opposite sides of the high-pressure sealing container 1-1 are provided with glass observation windows 1-2, and the positions of the two glass observation windows 1-2 are corresponding , for plane coherent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com