Chemical raw material processing reaction device

A technology for reaction equipment and chemical raw materials, which is applied in the field of chemical raw material processing and reaction equipment, can solve the problems that reaction components cannot be fully mixed, affect the reaction rate, etc., and achieve the effects of simple structure, accelerated reaction process and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

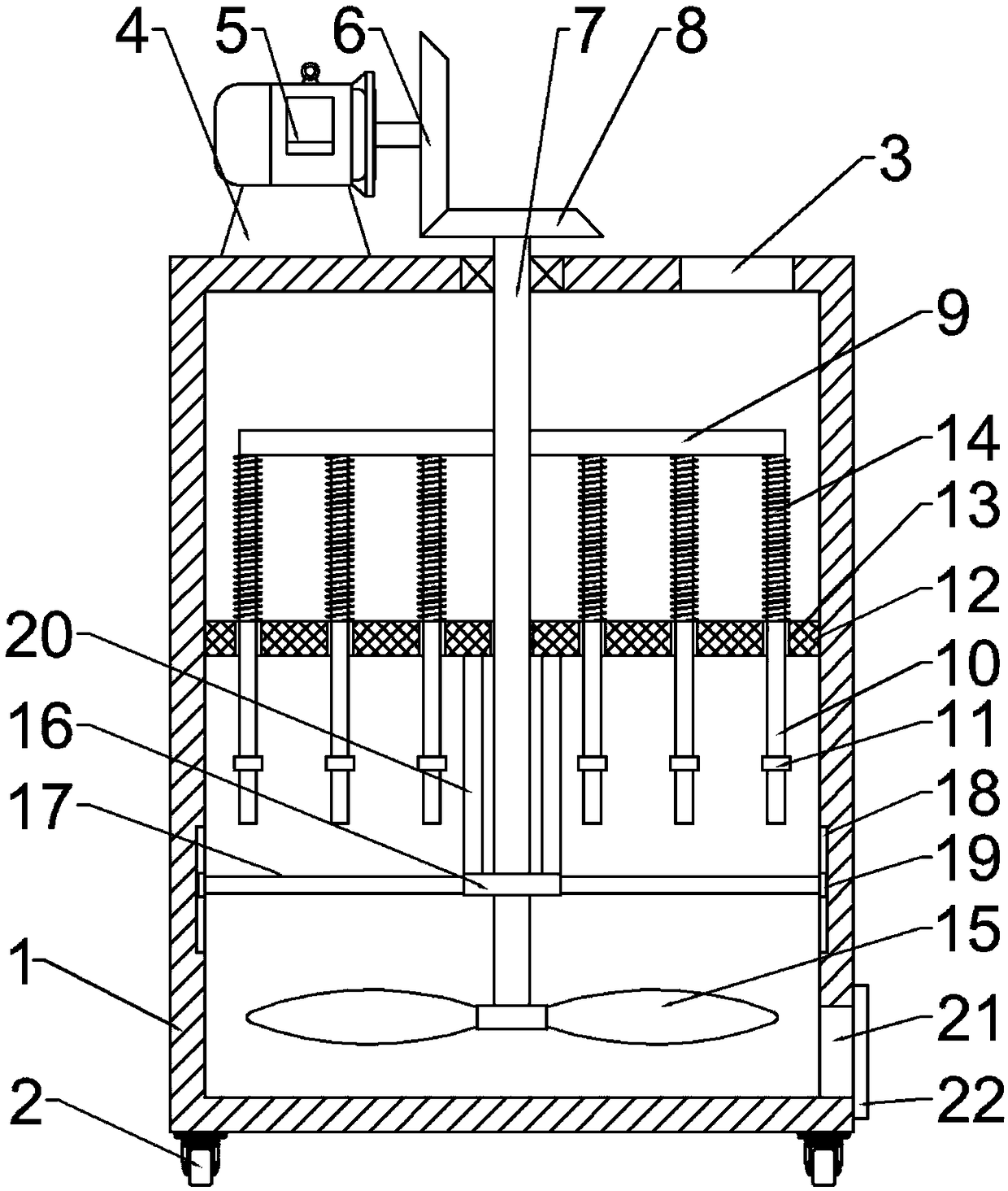

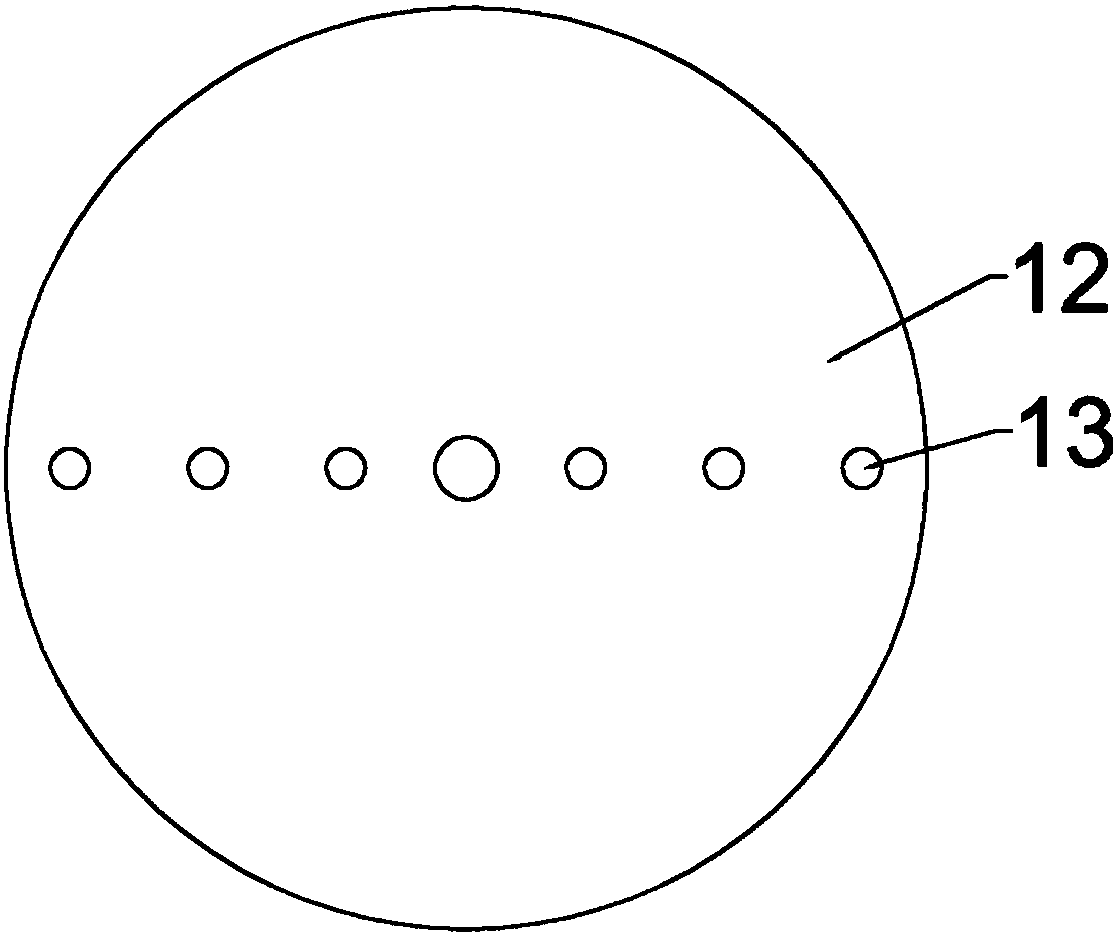

[0019] see Figure 1-2 , a processing and reaction equipment for chemical raw materials, comprising a housing 1, a motor base 4 is fixedly connected to the left side of the top of the housing 1, a motor 5 is fixedly connected above the motor base 4, and the output end of the motor 5 is fixedly connected There is a driving bevel gear 6, the top of the housing 1 is rotatably connected to a stirring shaft 7, and the top of the stirring shaft 7 is fixedly connected to a driven bevel gear 8, the driven bevel gear 8 is meshed with the driving bevel gear 6, and the outer side above the stirring shaft 7 A horizontal rotating rod 9 is fixedly connected, and a number of longitudinal stirring rods 10 are vertically and fixedly connected below the horizontal rotating rod 9. An overflow plate 12 is slidably connected to the inside of the housing 1, and a plural...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com