Washing machine

A washing machine and integrated technology, applied in the field of washing machines, can solve the problems of easy deformation, reduced drying efficiency, hot air overflow, etc., and achieve the effects of reducing washing water overflow, improving drying efficiency, and improving sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

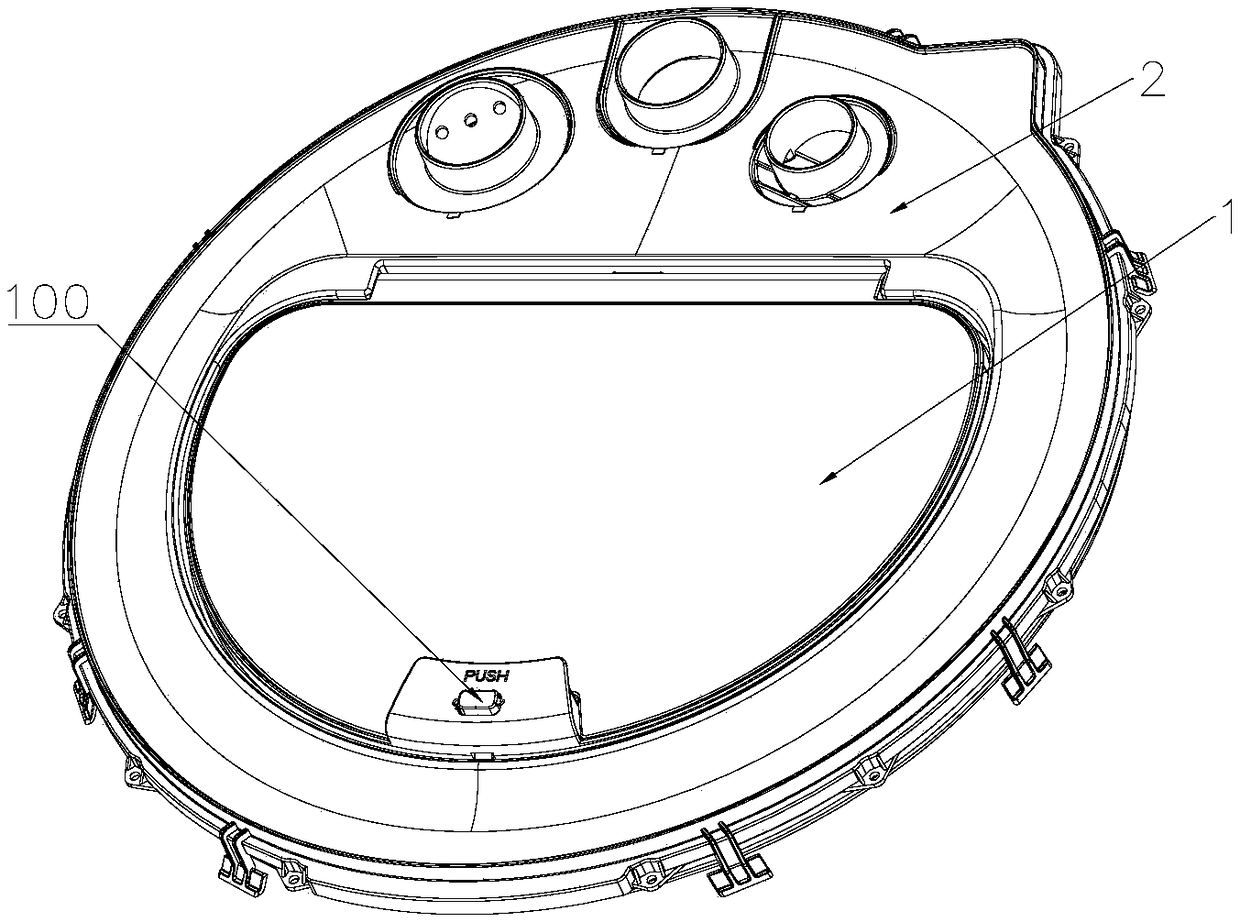

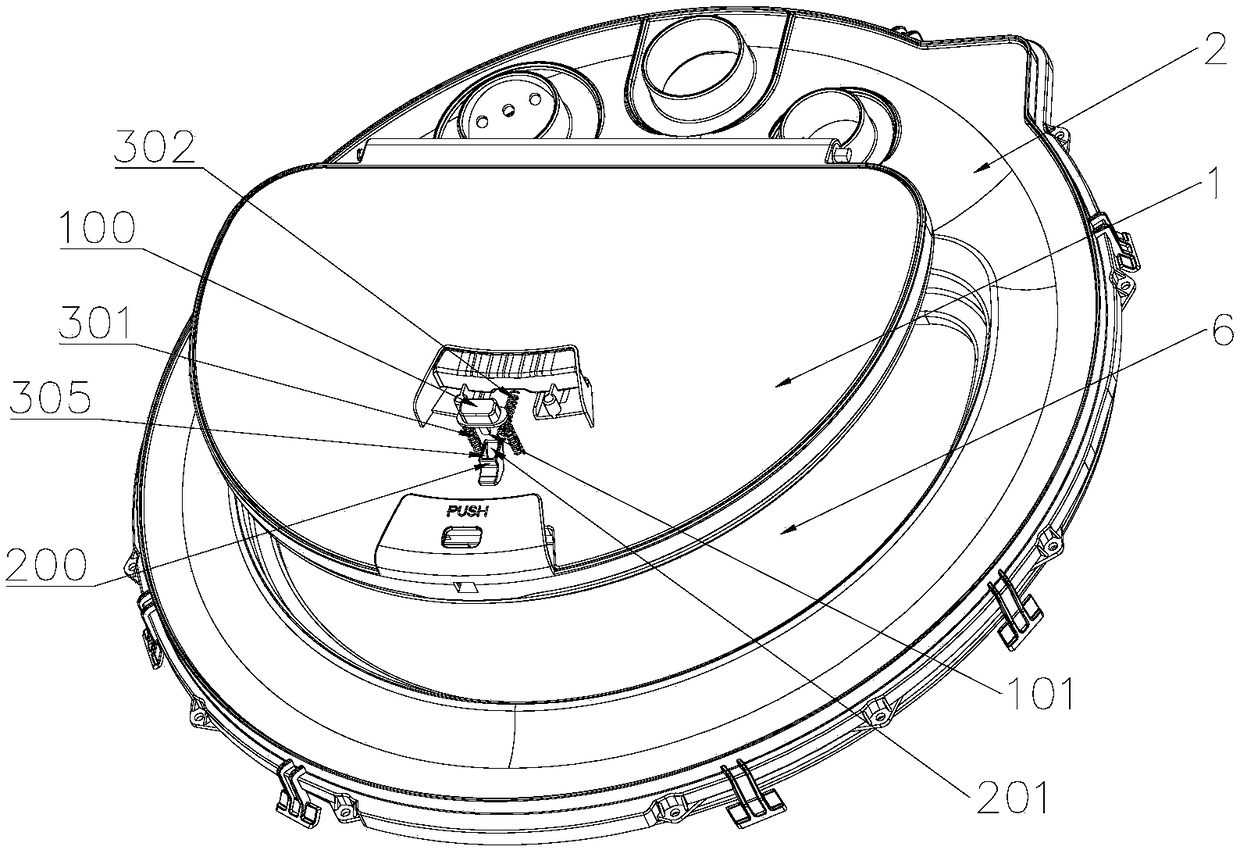

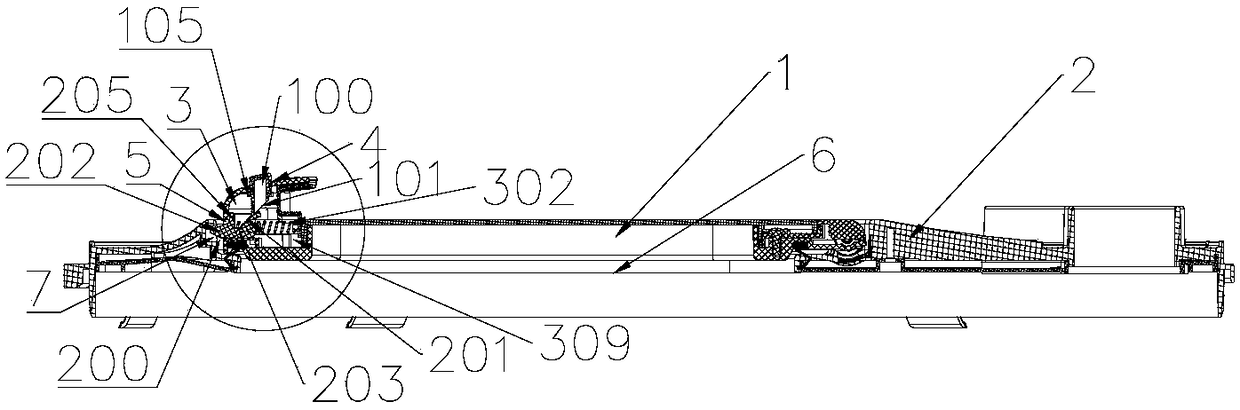

[0056] Such as Figure 1-4 As shown, a locking structure of the inner cover of a washing machine includes a lock tongue 200 arranged on the inner cover 1, a driving member 100 and a reset member 302, the driving member 100 has a first contact portion 101, and the lock tongue 200 There is a second contact portion 201 in sliding contact with the first contact portion 101; when the driver 100 moves in the first direction, the first contact portion 101 and the second contact portion 201 slide relative to each other to drive the lock tongue 200 to move in the second direction. The inner cover 1 is unlocked; when the driving member 100 is reset in the reverse direction of the first direction, the reset member 302 resets the lock tongue 200 .

[0057] By providing the first contact portion 101 and the second contact portion 201, the relative sliding of the first contact portion 101 and the second connecting portion converts the movement of the driving member 100 in the first directio...

Embodiment 2

[0067] Such as Figure 1-4 As shown, this embodiment is a further limitation of Embodiment 1. The locking tongue 200 includes a locking part 202 and a driving part 203 for locking the inner cover 1, and the second contact part 201 is located on the driving part 203, so The direction of the sliding surface extends from the locking portion 202 to the driving portion 203 toward the driving member 100 . The direction of the sliding surface extends from the locking part 202 to the driving part 203 to the direction of the driving part 100. When the driving part 100 moves in the first direction, a component force moving in the second direction is generated, and the locking part 202 is driven in the second direction. movement to unlock the inner cover 1.

[0068] The first direction is directed from the driving part to the direction of the lock tongue, and the second direction is directed from the locking part 202 to the direction of the driving part 203 .

[0069] Further, the firs...

Embodiment 3

[0085] Such as Figure 1-4As shown, this embodiment is a specific implementation of Embodiment 1 and Embodiment 2, a washing machine with an inner lid locking structure, the washing machine includes an outer tub, and an outer tub lid 2 is arranged on the outer tub , the outer barrel lid 2 is provided with a delivery port 6 for putting clothes, the inner cover 1 is hinged with the outer barrel cover 2, and the edge of the delivery opening 6 is provided with a lock groove 7 corresponding to the lock tongue 200, and the lock tongue 200 moves along the second direction and escapes from the lock groove 7, the inner cover 1 is unlocked, and when the driving member 100 is reset in the opposite direction of the first direction, the reset member 302 resets the lock tongue 200.

[0086] The inner cover 1 is horizontally arranged on the washing machine, and the inner cover 1 has an accommodating cavity 3 , and the locking tongue 200 , the button 100 and the return spring 302 are arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com