Adjustable ridging machine

An adjustable and ridge-building technology, which is applied to agricultural machinery, adjustment devices, and lifting devices for agricultural machinery, can solve the problems that the size of the ridge-making mechanism cannot be adjusted, the soil particles are easy to slip and scatter, and increase the cost of planting, so as to achieve the efficiency of ridge-making and high stability, saving labor and time costs, and avoiding planting costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to better understand the present invention, the present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

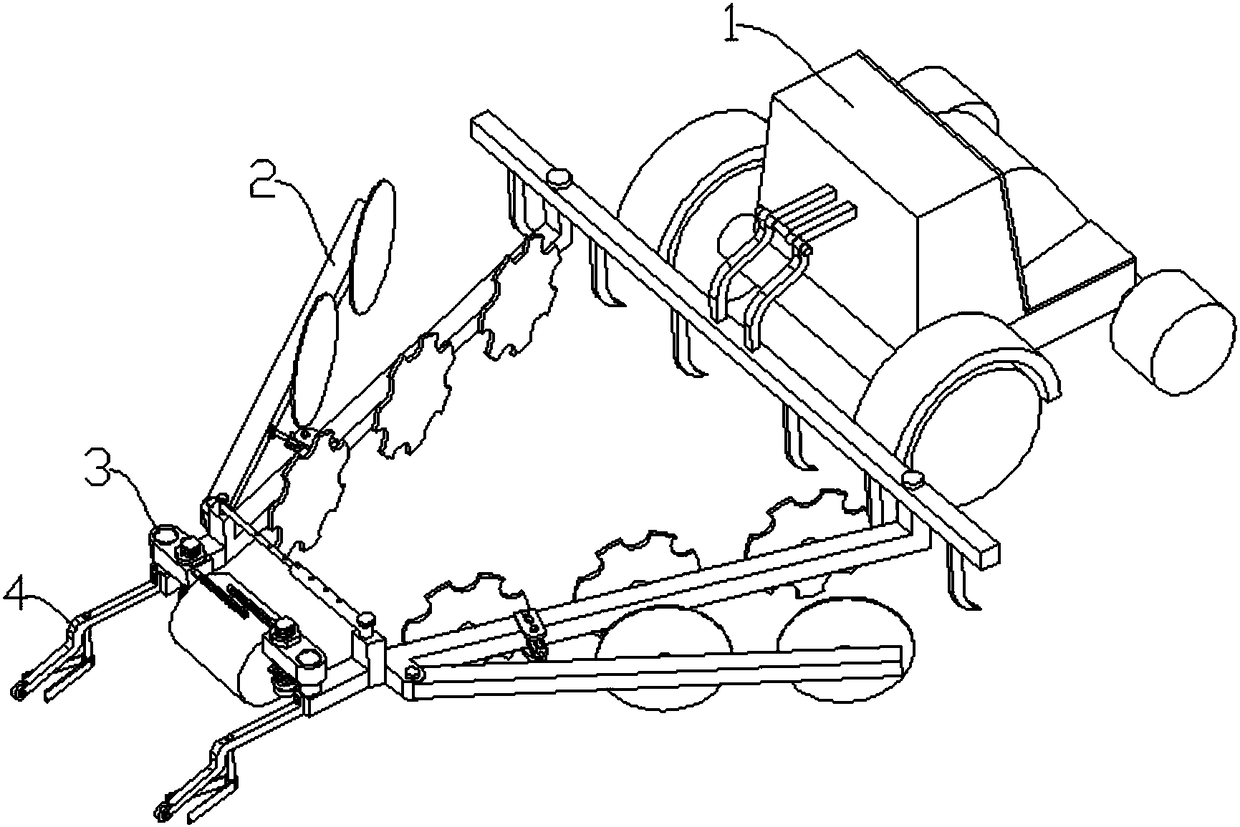

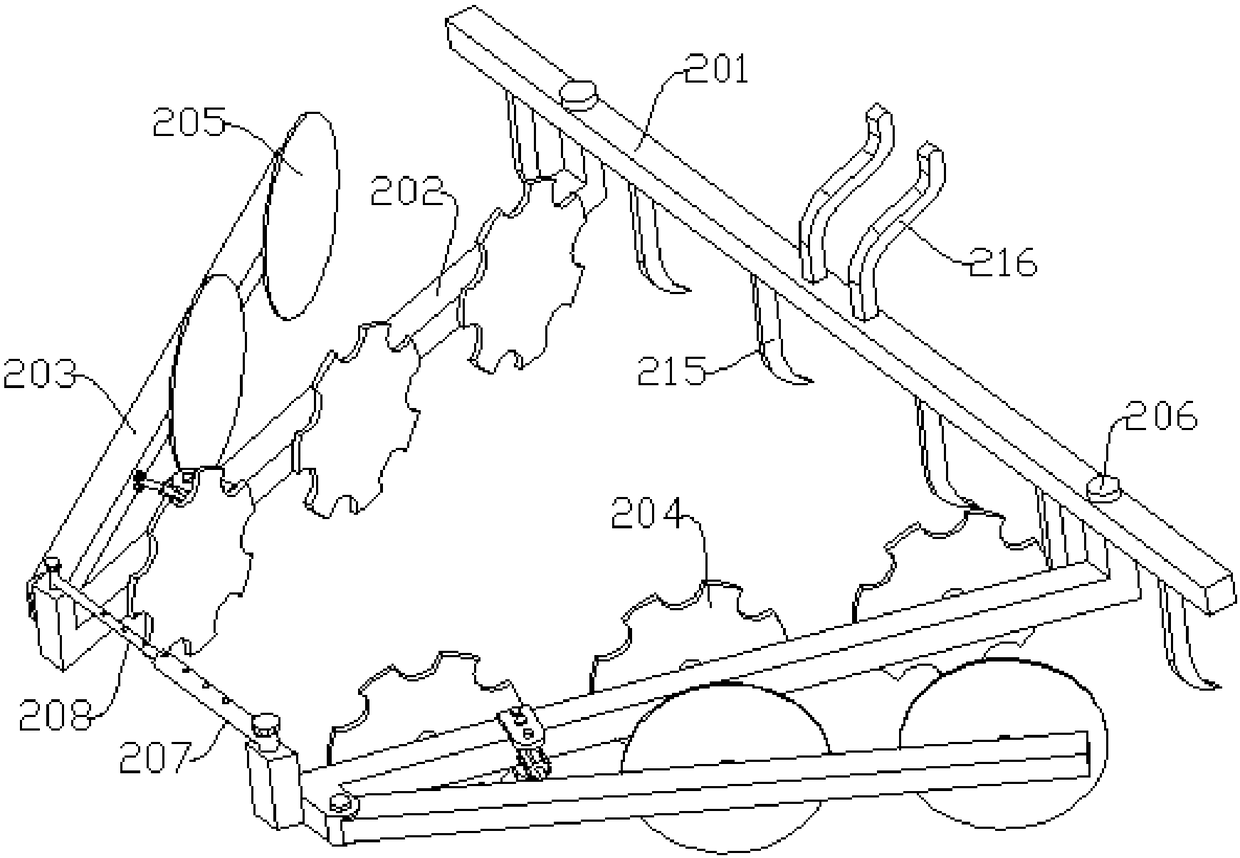

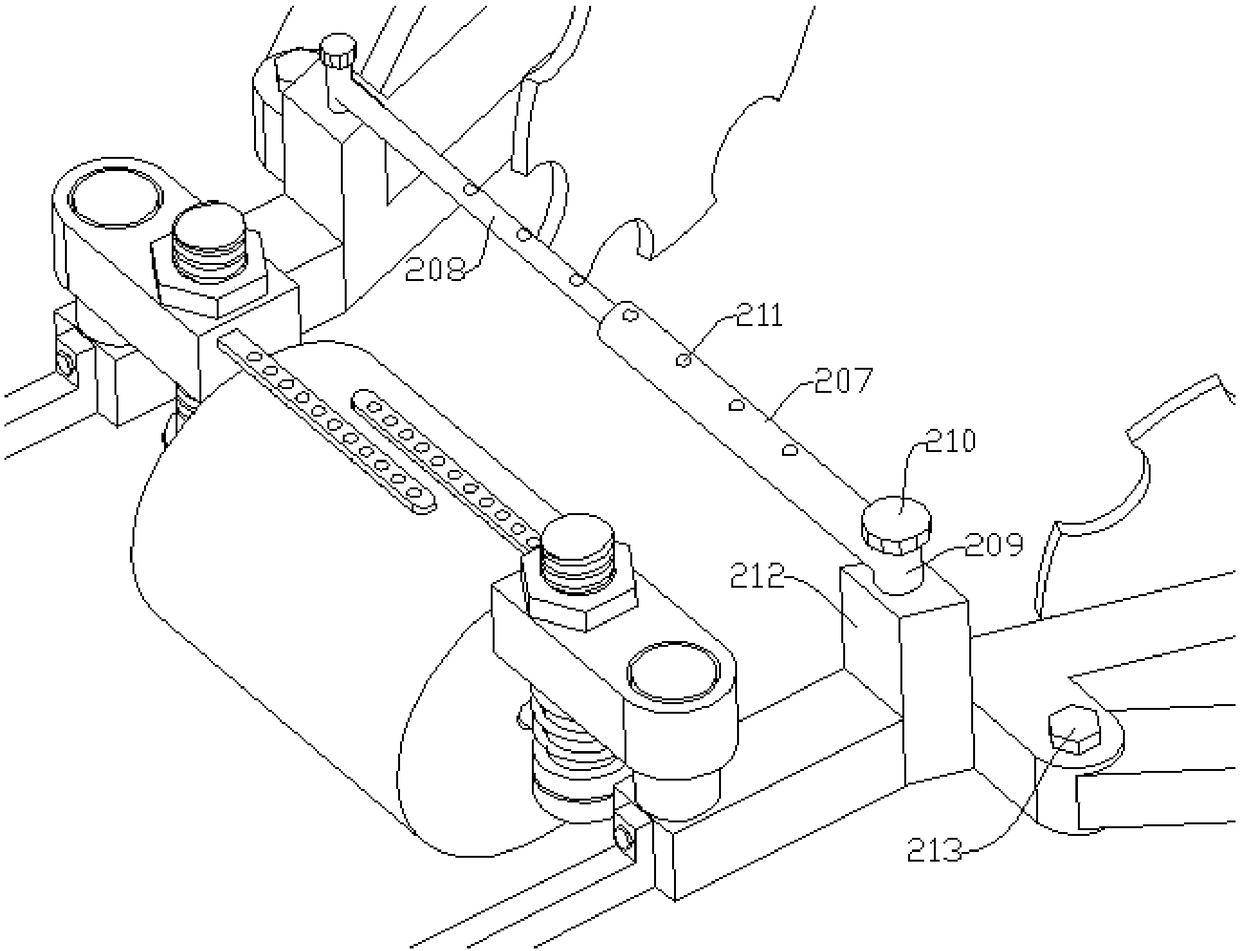

[0026] Ridging machine provided by the invention, such as figure 1 , comprising a driving head 1 and a ridge making mechanism 2, the ridge making mechanism 2 is detachably connected behind the driving head 1, and a tamping mechanism 3 is provided at the tail of the ridge making mechanism 2. As the power source of the entire ridge building machine, the drive head 1 is mainly equipped with driving equipment such as an engine, which is used to provide the forward driving force of the whole device. Seats and other structures can also be provided as required, or the existing head can be directly used Instead, the ridge-making mechanism 2 is used for ridge-riding of cultivated land, and the compacting mechanism 3 can form a ridge platform and compact it in time after ridge-forming, so as to improve the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com