Direct-writing preparation method of hollow carbon nanosphere/Al/Fe2O3-based nano thermite

A nanosphere and hollow carbon technology, applied in nanocarbon, nanotechnology, nanotechnology and other directions, can solve the problems of heat absorption and poor heat transfer performance, and achieve the effect of simple operation and good universality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A kind of hollow carbon nanosphere / Al / Fe 2 o 3 The direct writing preparation method of nano-based thermite comprises the following steps:

[0032] Step 1, with 0.32gAl and 1.6gFe 2 o 3 Add 50mL of n-hexane, stir, and sonicate to obtain a uniform suspension, and vacuum-dry the suspension to obtain a dry powder mixture; the ultrasonic power is 35kHz, and the power is 300W;

[0033] Step 2, mix the dry powder mixture with 1.6g of nitrocellulose solution (14wt%), and grind to obtain a slurry; the grinding adopts a stirring grinder, the grinding temperature is 10°C, the grinding time is 120min, and the grinding speed is 1200r / min ;

[0034] Step 3. Pass the slurry through a 0.5mm nozzle ink direct writing printing and then vacuum drying to obtain hollow carbon nanospheres / Al / Fe 2 o 3 Nano-based thermite (HCS-0).

Embodiment 2

[0036] A kind of hollow carbon nanosphere / Al / Fe 2 o 3 The direct writing preparation method of nano-based thermite comprises the following steps:

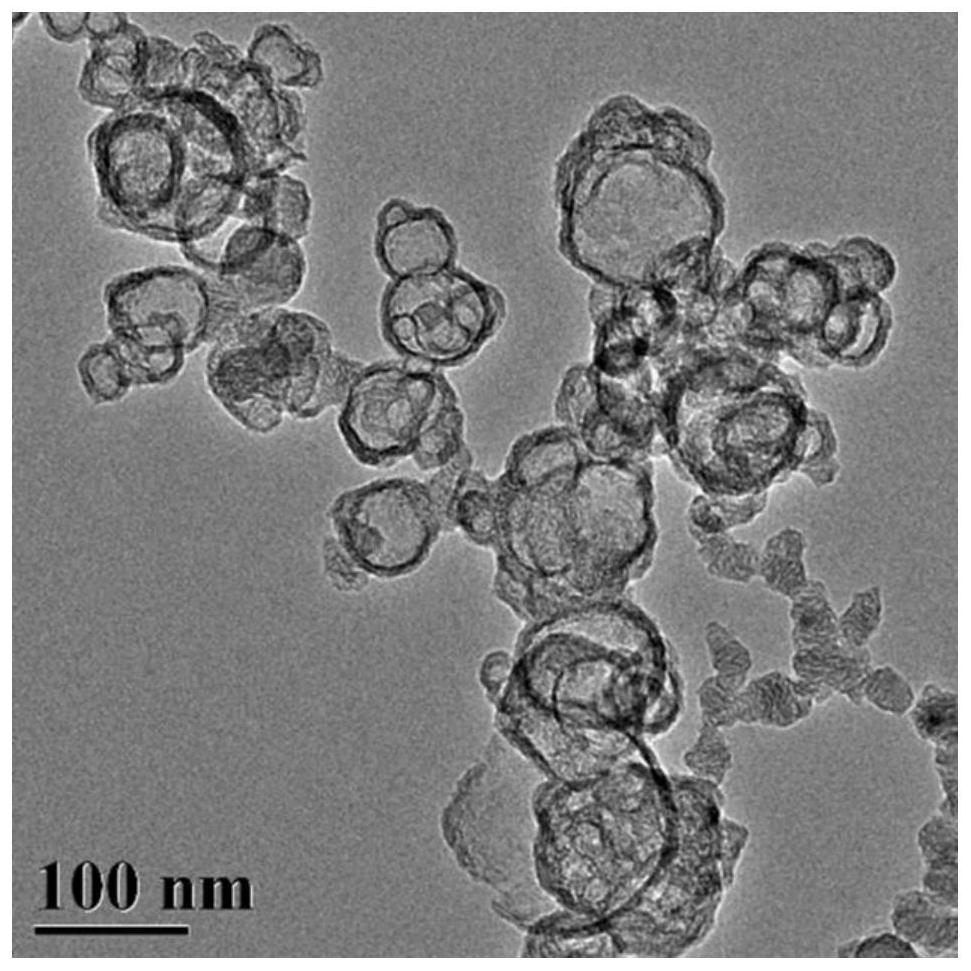

[0037] Step 1, 0.016g hollow carbon nanospheres, 0.32gAl and 1.6gFe 2 o 3 Add in 50mL of n-hexane, stir, and ultrasonically obtain a uniform suspension, and vacuum-dry the suspension to obtain a dry powder mixture; the ultrasonic power is 35kHz, and the power is 300W; the preparation method of the hollow carbon nanospheres is as follows: 35mmol NaN 3 And the mixture of 1.6g fluorinated graphite is added to the autoclave, and then the mixture is heated, under N 2 Under the atmosphere, the temperature was raised to 320°C and kept at this temperature until the pressure and temperature deflagration reaction occurred due to heat release, cooled naturally, and the product was collected, washed 3 times with distilled water, and vacuum-dried at 60°C for 24 hours to obtain hollow carbon nanospheres;

[0038] Step 2, mix the dry powder ...

Embodiment 3

[0041] A kind of hollow carbon nanosphere / Al / Fe 2 o 3 The direct writing preparation method of nano-based thermite comprises the following steps:

[0042] Step 1, 0.032g hollow carbon nanospheres, 0.32gAl and 1.6gFe 2 o 3Add in 50mL of n-hexane, stir, and ultrasonically obtain a uniform suspension, and vacuum-dry the suspension to obtain a dry powder mixture; the ultrasonic power is 35kHz, and the power is 300W; the preparation method of the hollow carbon nanospheres is: 35mmol NaN 3 And the mixture of 1.6g fluorinated graphite is added to the autoclave, and then the mixture is heated, under N 2 Under the atmosphere, the temperature was raised to 320°C and kept at this temperature until the pressure and temperature deflagration reaction occurred due to heat release, cooled naturally, the product was collected, washed 3 times with distilled water, and vacuum dried at 60°C for 24 hours to obtain hollow carbon nanospheres;

[0043] Step 2, mix the dry powder mixture with 1.6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com