Copper oxychloride particulate matter and preparation method thereof

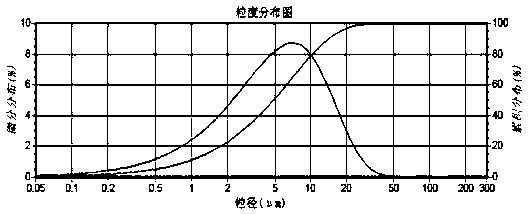

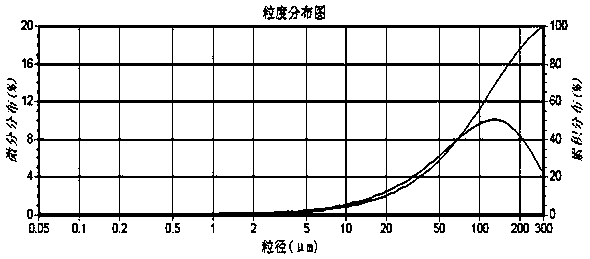

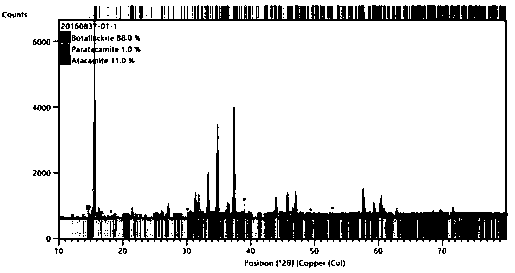

A technology of copper chloride and particles, which is applied in the field of basic copper chloride particles and its preparation, can solve the problems of dust, large size, etc., and achieve the effect of less dust, uniform particles and high copper content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0051] Prepare an ammonium chloride solution with an ammonia nitrogen concentration of A g / L, heat it to B°C, and then add copper chloride precursor and ammonium chloride to the above ammonium chloride solution at the same time in the way of co-current feeding according to the flow ratio C Precursor solution, maintain the reaction pH value between D, stop feeding until the basic cupric chloride solid just begins to appear in the reaction system, heat preservation reaction E h; then add the copper chloride raw material solution simultaneously in the mode of co-current feeding 1. Alkaline copper-containing solution, maintain the reaction pH value between F, react G h, discharge and wash, and obtain the basic copper chloride particles after drying;

[0052] Described cupric chloride precursor solution is that copper content is H g / L, and pH is the cupric chloride acidic precursor solution of 1;

[0053] In the ammonium chloride precursor solution, the ammonium chloride content is...

Embodiment 1

[0093] Basically the same, the difference is that after adding the precursor, the pH value D of the system is maintained at 5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com