Simple glass fixing clamping plate molding mechanism

A technology for fixing splints and forming mechanisms, applied in metal processing equipment and other directions, can solve problems such as unsatisfactory effect and troublesome forming, and achieve the effect of good effect and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

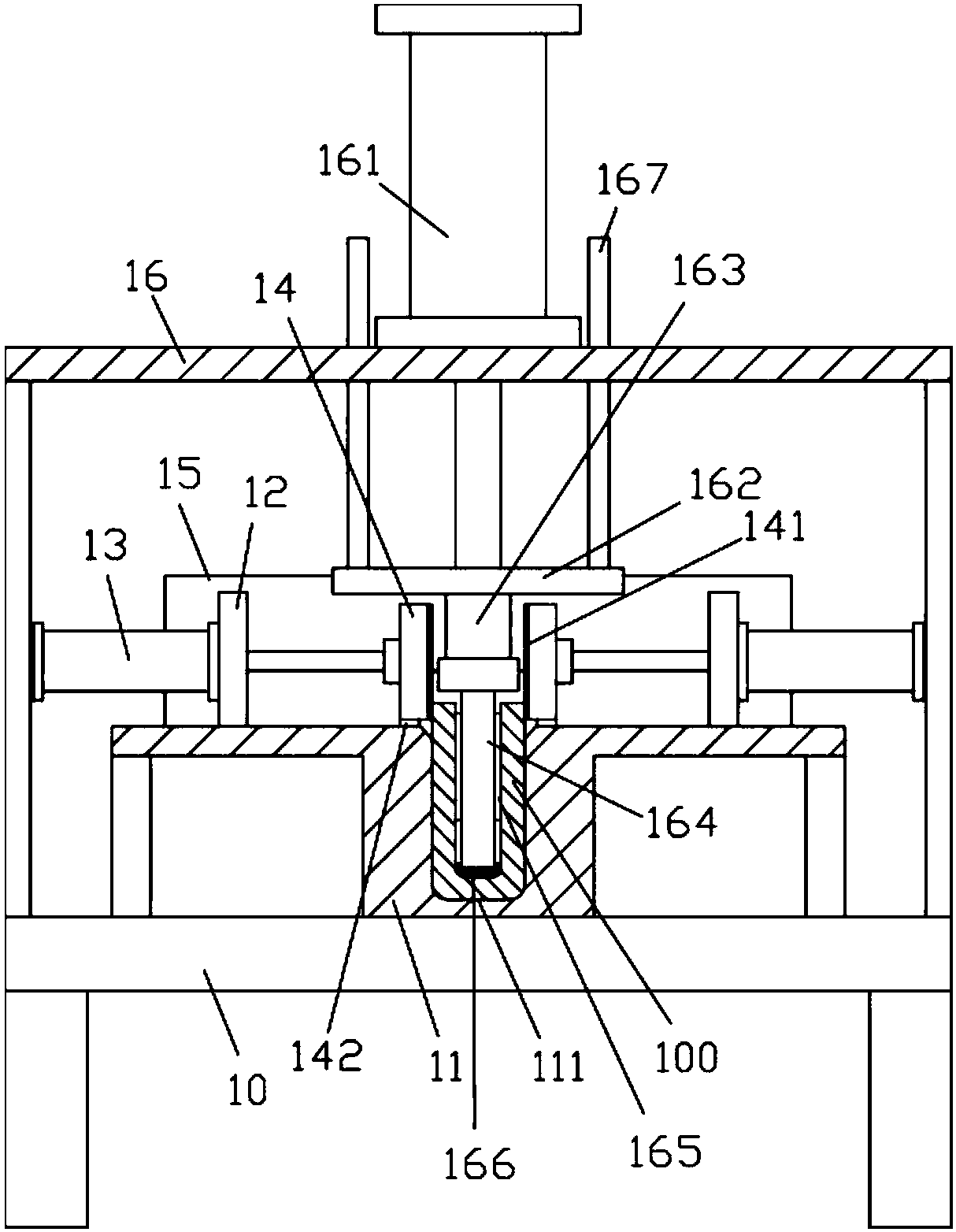

[0015] Examples, see e.g. figure 1 Shown, a kind of simple and easy glass fixed splint molding mechanism comprises frame 10, and the middle part of the top plate of described frame 10 is fixed with molding die block 11, and the middle part top surface of molding die block 11 has middle molding groove 111, and the molding die The top left and right sides of block 11 are fixed with vertical support plate 12, and the limit oil cylinder 13 is fixed on the outer wall of vertical support plate 12, and the push rod of limit oil cylinder 13 passes through vertical support plate 12 and is fixed with lateral pressure. Tight block 14, the front portion and the rear portion of the top surface of forming die block 11 are all fixed with baffle plate 15;

[0016] The top surface of the top plate of the frame 10 is fixed with an upper support frame 16, and the middle part top surface of the top plate of the upper support frame 16 is fixed with a middle stamping oil cylinder 161, and the push ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com