Abrasive particle parameter optimal design method for saw web with abrasive particles arranged in parameterized mode

A design method and parametric technology, applied in the direction of metal sawing equipment, electrical digital data processing, cutting tools of sawing machine devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] In this embodiment, the optimal design of abrasive grain parameters on the surface of the saw blade is aimed at obtaining high processing efficiency. The workpiece is G603 granite, and the processing efficiency is 1200m 2 / s. The sawing amount given by the user gives the set sawing amount (sawing speed v s =45m / s, feed speed v w =6m / min, sawing depth a p is 10mm).

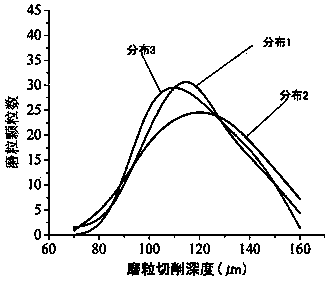

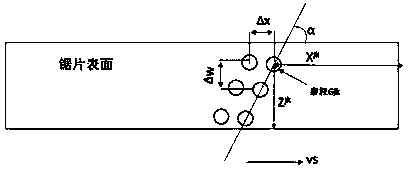

[0047] (1) Set the target abrasive grain cutting thickness distribution according to the processing results, such as figure 1 The distribution 1 is shown in 1; the given sawing amount adopts the value given by the user; the abrasive grain parameters on the surface of the saw blade are initialized, and the abrasive grain size and edge height are both normal distributions. The parameters are: particle size N(550,0.25), The blade height is N(67,0.15), Δw=1.5mm, ΔX=3mm.

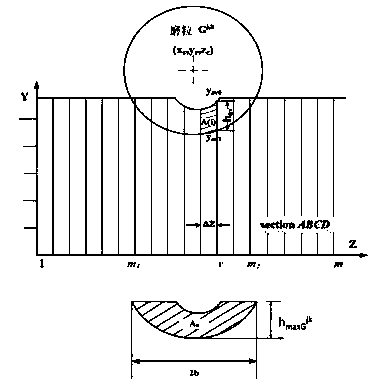

[0048] (2) Calculate the thickness distribution of the abrasive grains on the surface of the saw blade and the amount of sawing, and cal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com