A Grinding Amount Design Method Based on the Constraints of Abrasive Particle Thickness Distribution

A technology of grinding amount and design method, which is applied in the direction of design optimization/simulation, special data processing application, complex mathematical operation, etc., to achieve the effect of avoiding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

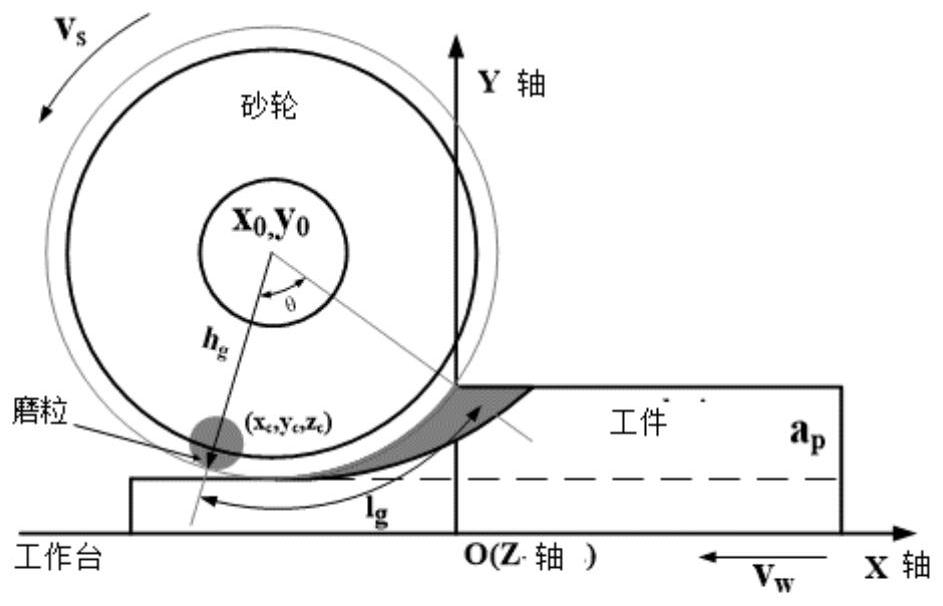

[0049] In this embodiment, the abrasive tool is a grinding wheel, and the optimal design of the grinding amount is carried out with the goal of obtaining a good machined surface quality. The workpiece is No. 45 steel, and the surface roughness Ra of the processing result is expected to be less than 0.4um. The user has given the parameters of the abrasive grain on the surface of the grinding wheel. The grain size, position and edge height are all normal distributions. The parameters are: grain size N(550 ,0.25), position N(0.1,0.4), the blade height is N(67,0.15).

[0050] Specific optimization design process:

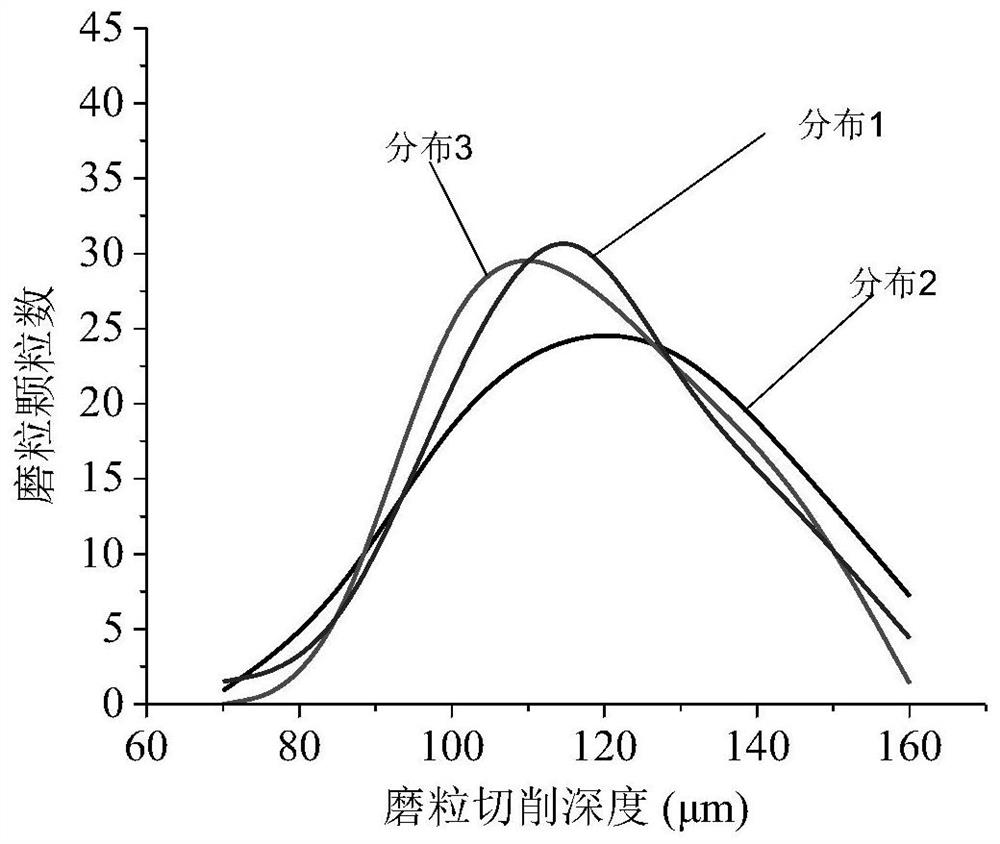

[0051] (1) Set the target abrasive grain cutting thickness distribution according to the processing results, such as figure 1 The distribution 1 of the given grinding wheel is shown in 1; the grinding parameters of the given grinding wheel adopt the value given by the user; a set of grinding amount is initially given (grinding speed v s =45m / s, feed speed v w =20m / mi...

Embodiment 2

[0073] The grinding tool is a grinding wheel, the workpiece is a TC4 titanium alloy, and the expected processing efficiency is 600mm 3 / s, the grinding roughness is 0.35um. Given grinding wheel parameter 3, the user only provided a real grinding wheel without specific parameters.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com