Easily-detached automatic rotation equipment

An automatic rotation and easy disassembly technology, applied in the directions of transportation, packaging, conveyors, etc., can solve problems such as the difficulty of dismantling the scale conveyor belt and the inability to meet daily cleaning, so as to facilitate daily cleaning work, solve the difficulty of disassembly and installation, and reduce maintenance costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

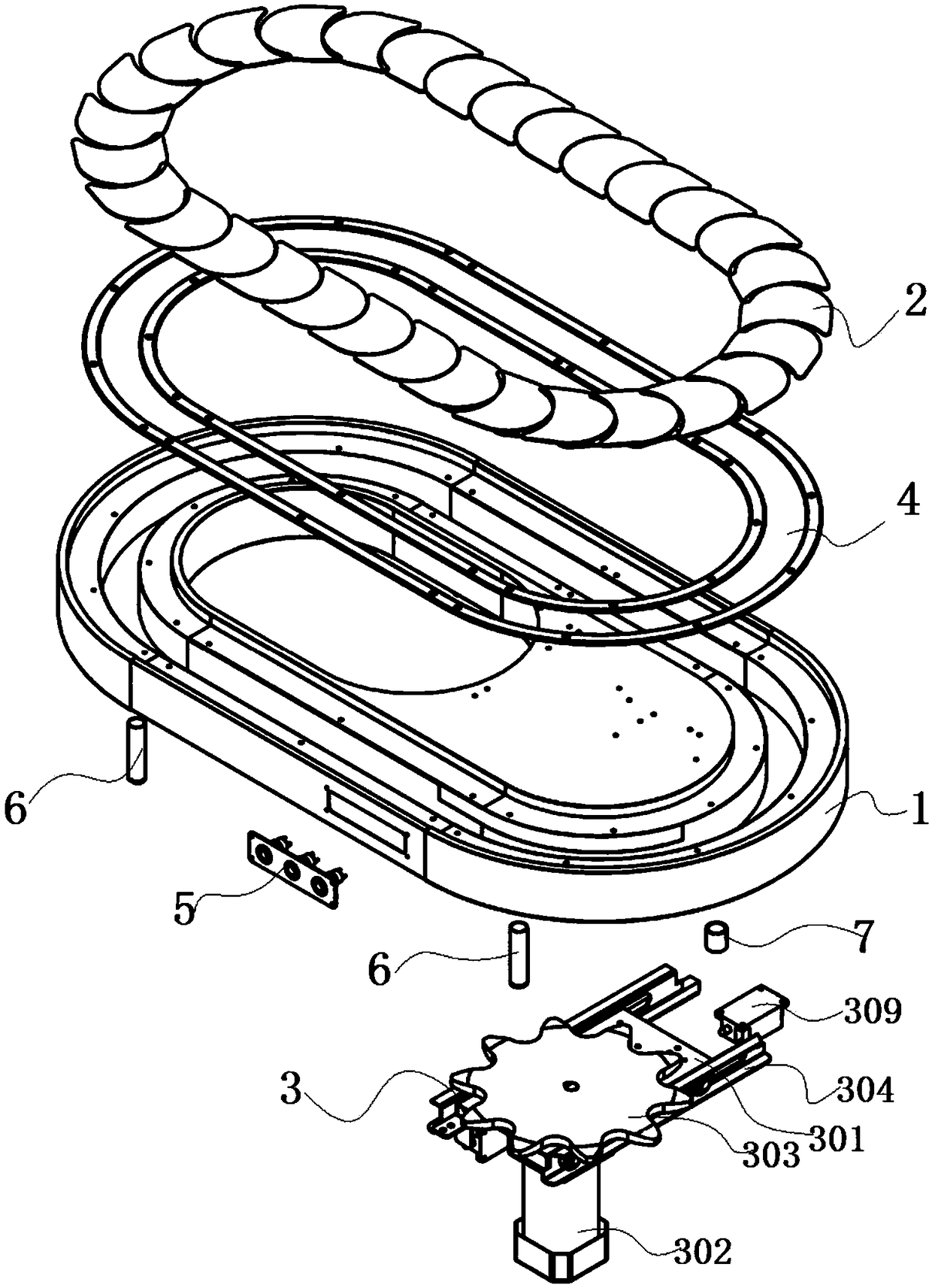

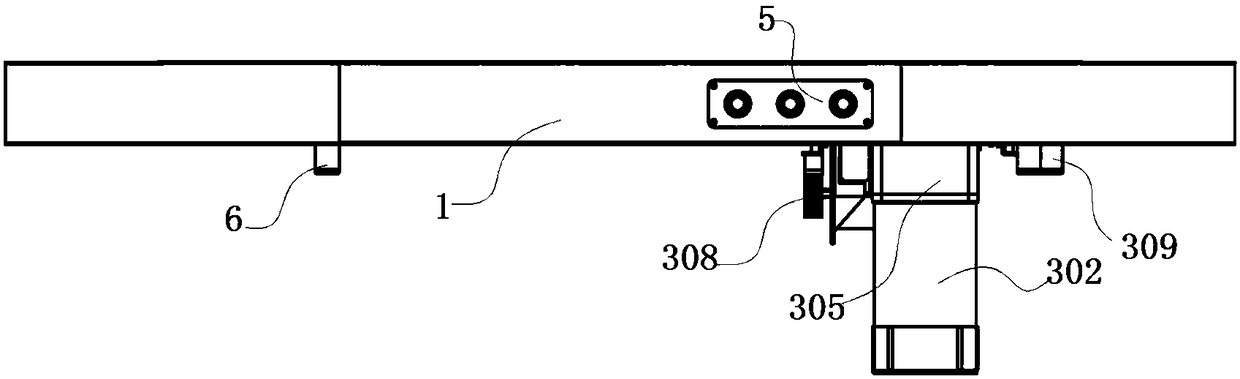

[0022] like Figure 1-5 As shown, the specific embodiment of the present invention is an easy-to-disassemble automatic rotary device, including a rotary base 1, a scale conveyor belt 2, and a sprocket module 3. The scale conveyor belt 2 is located in the rotary base 1, and the The sprocket module 3 is driven and connected with the scale conveyor belt 2;

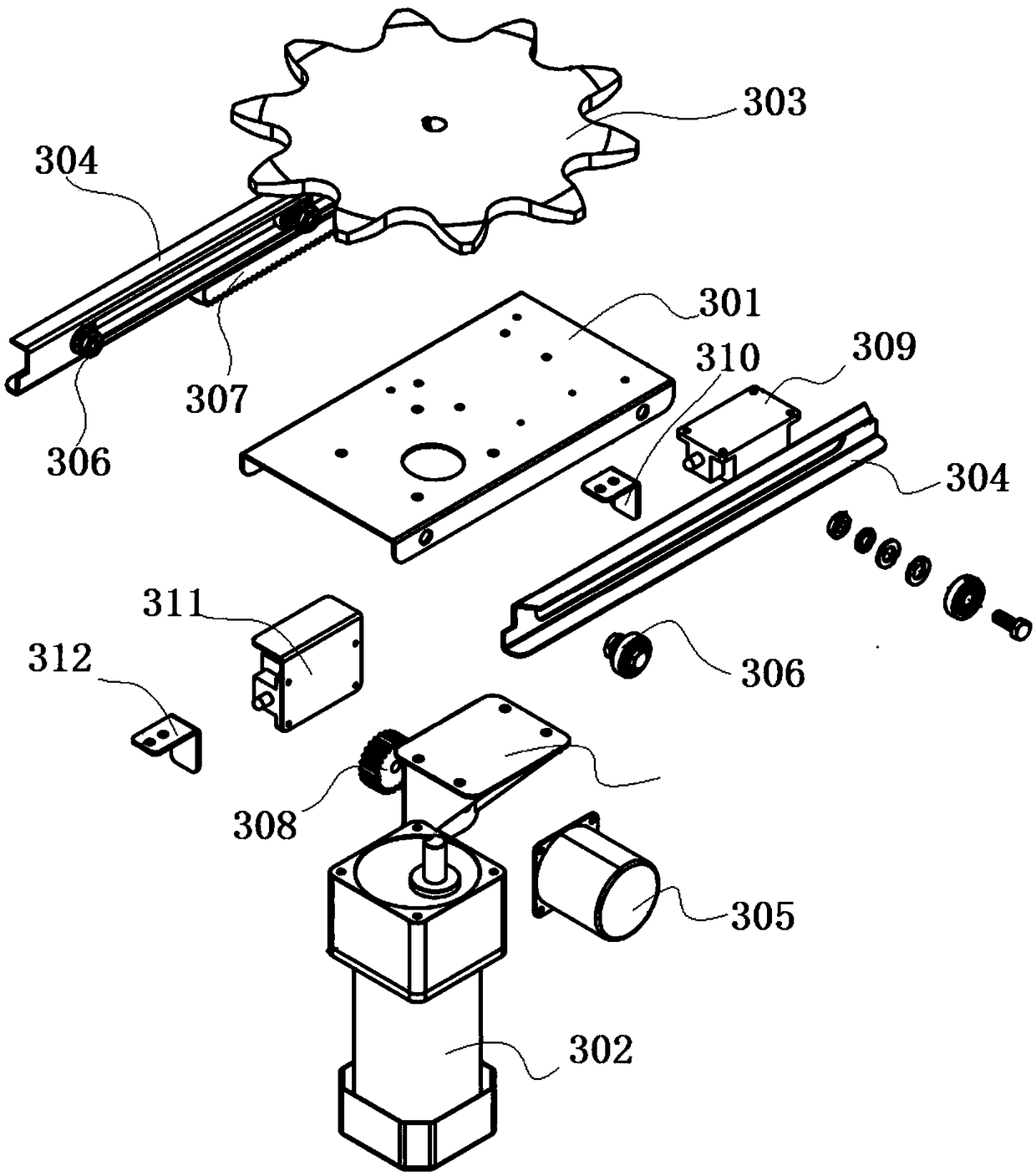

[0023] The sprocket module 3 includes a fixed seat 301, a rotary motor 302, a sprocket wheel 303, a reciprocating motor 305, and a slide rail 304. The rotary motor 302 and the reciprocating motor 305 are respectively fixedly installed under the fixed seat 301. The fixed seat Both sides of 301 are movably connected with slide rail 304 through bearings 306, and fixed seat 301 can slide back and forth along slide rail 304. The reciprocating motor 305 is drivingly connected with the ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com