Automatic paper circle blanking device and method

An automatic blanking and blanking technology, applied in the field of machinery, can solve the problems of slow speed, high labor intensity, uneven cutting effect, etc., and achieve the effect of improving production efficiency, high degree of automation, and high degree of product uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "inner" and "outer ” refer to directions towards or away from the geometric center of a particular part, respectively.

[0024] This patent provides a variety of parallel schemes, and the different expressions belong to the improved scheme based on the basic scheme or the parallel scheme. Each scheme has its own unique characteristics.

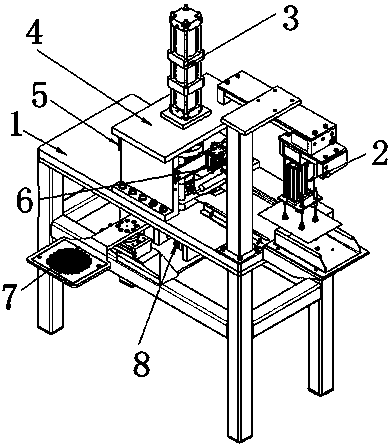

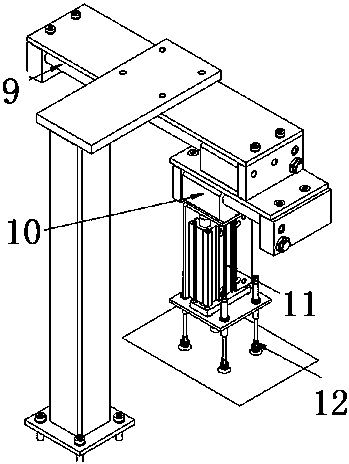

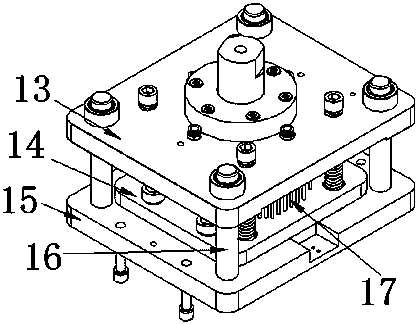

[0025] The automatic punching paper circle device is characterized in that it includes a mounting frame 1, a platform is included above the mounting frame 1, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com