Mining monorail crane lifting and conveying device

A technology of lifting device and transportation device, which is applied in the directions of transportation and packaging, track system, running mechanism, etc. It can solve the problems of large volume of monorail crane device, small equipment lifting space, and large driving force, so as to achieve small space occupation and high efficiency. Utilization rate, effect of volume reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

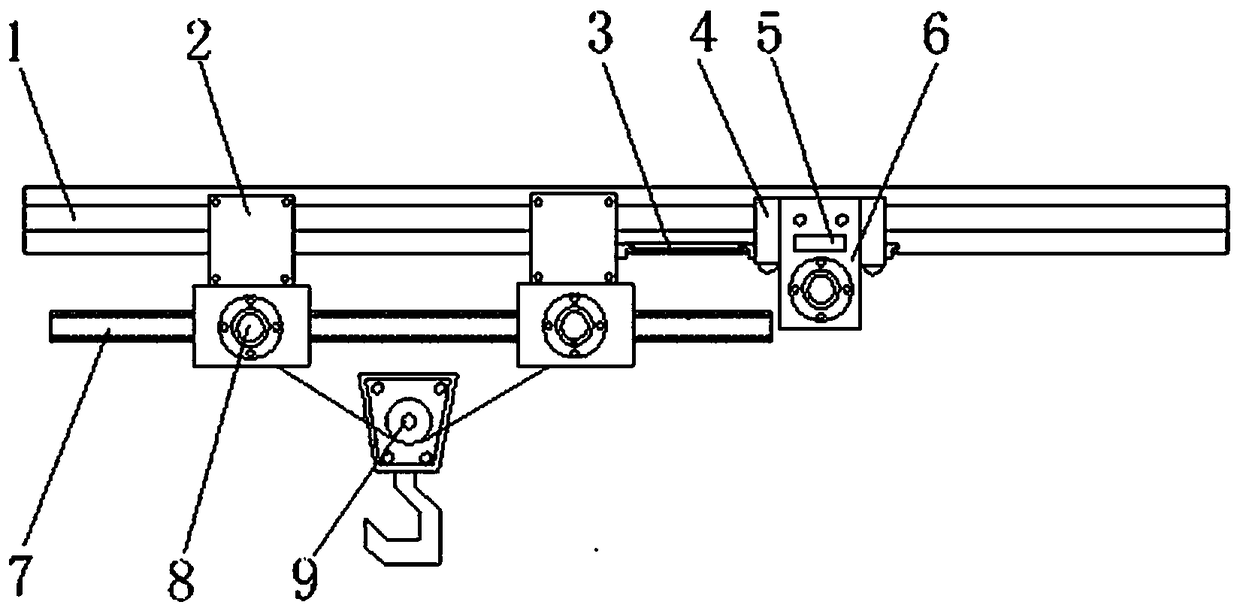

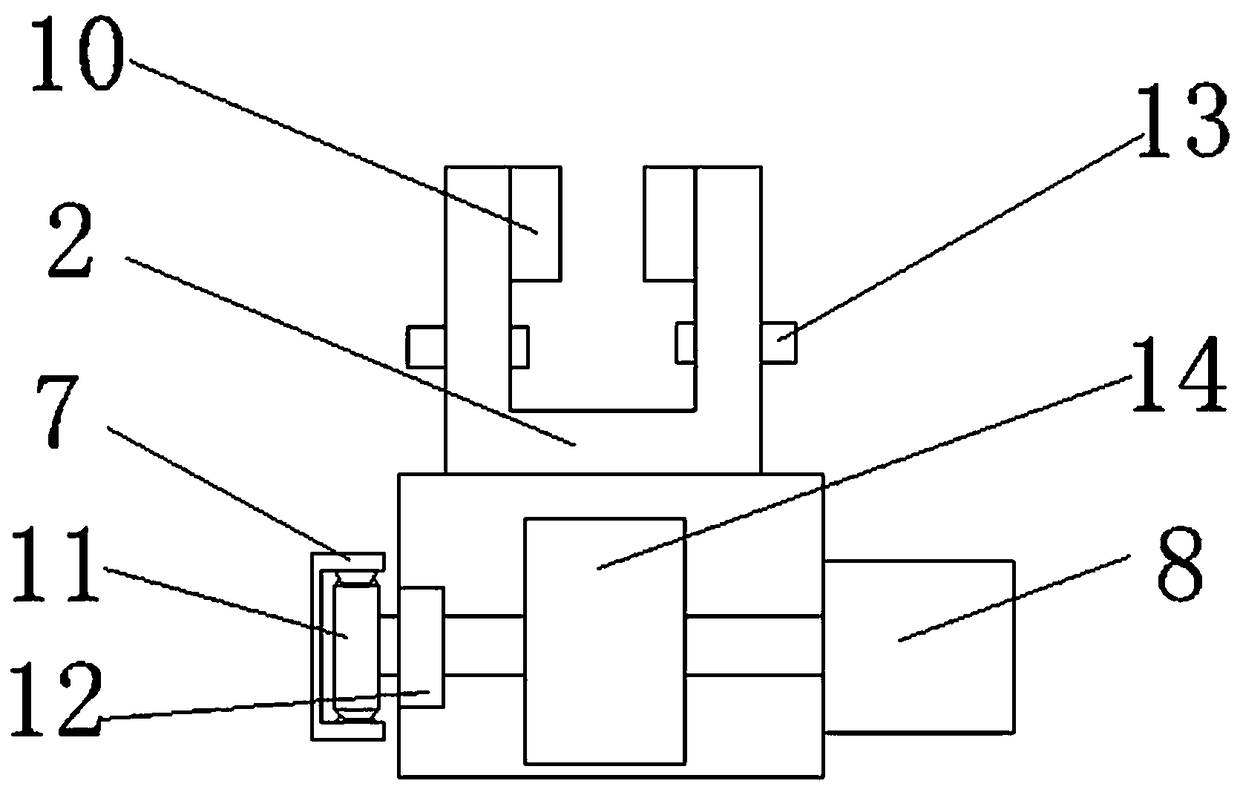

[0020] A mining monorail crane hoisting and transporting device, comprising a guide rail 1, a traction device 6 and a lifting device 2 are arranged on the guide rail 1, a braking device 4 and a guide wheel 5 are arranged in the traction device 6, and the traction device 6 and the The lifting devices 2 are connected by a draw bar 3, a pulley 10 and a guide wheel 13 are arranged in the lifting device 2, and a lifting motor 8 is arranged under the lifting device 2, which is connected with a coil 14 through a shaft, and the coil 14 passes through The cable is connected with the hook 9, the motor 8 is connected with the gear 12 through the shaft and the differential 12, and the outside of the gear 12 is provided with a bracket 7. An application method of a mining monorail crane lifting transport device is: the device is arranged on the guide rail 1, and the lifting device 2 is controlled to move on the guide rail through the traction device 6, the brake device 4 and the draw bar 3. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com