Small sewage filtering tank convenient to move

A filter tank and sewage technology, applied in the direction of filtration treatment, biological water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of inability to move, not flexible enough, high energy consumption, etc., to reduce investment threshold and reduce energy consumption consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

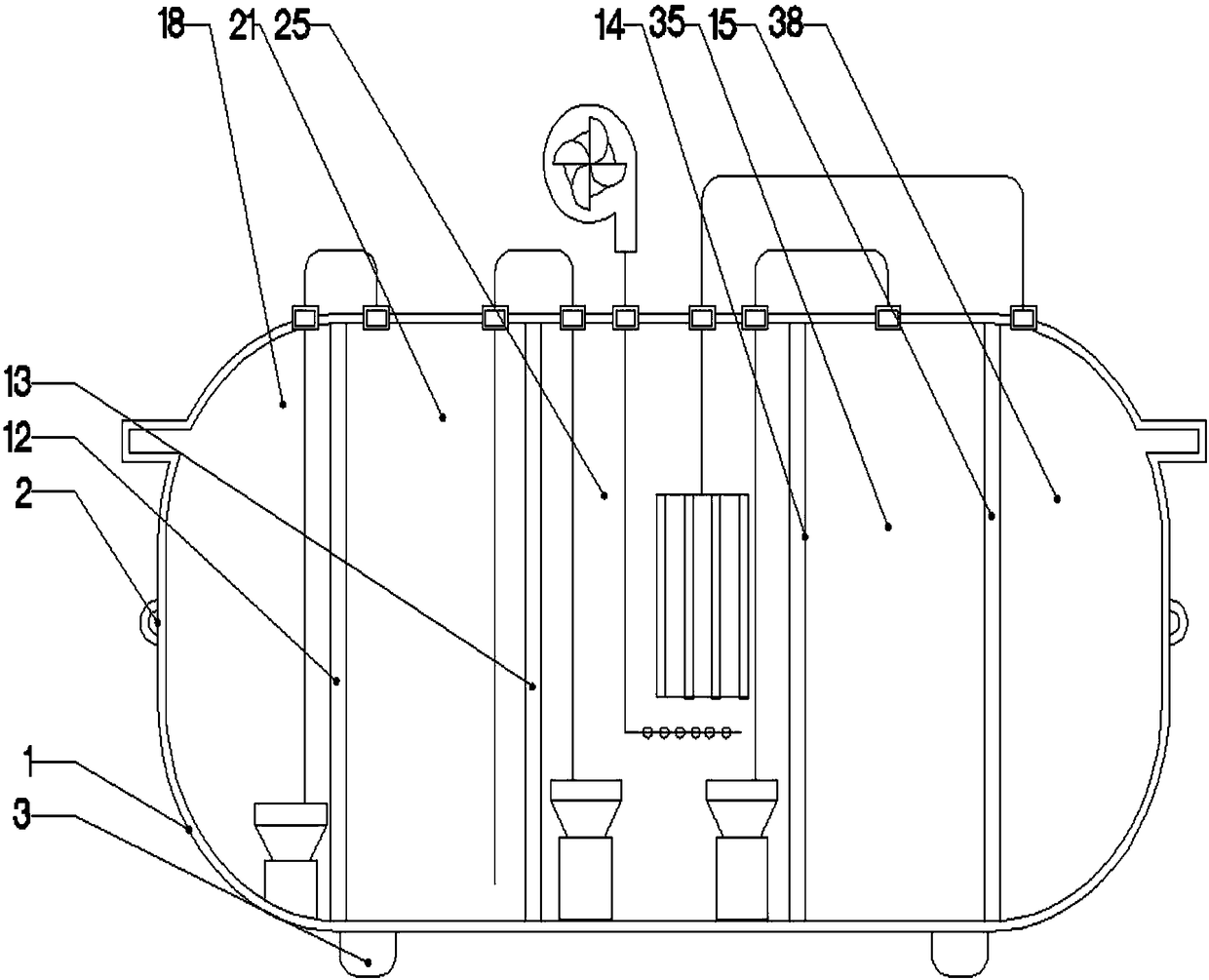

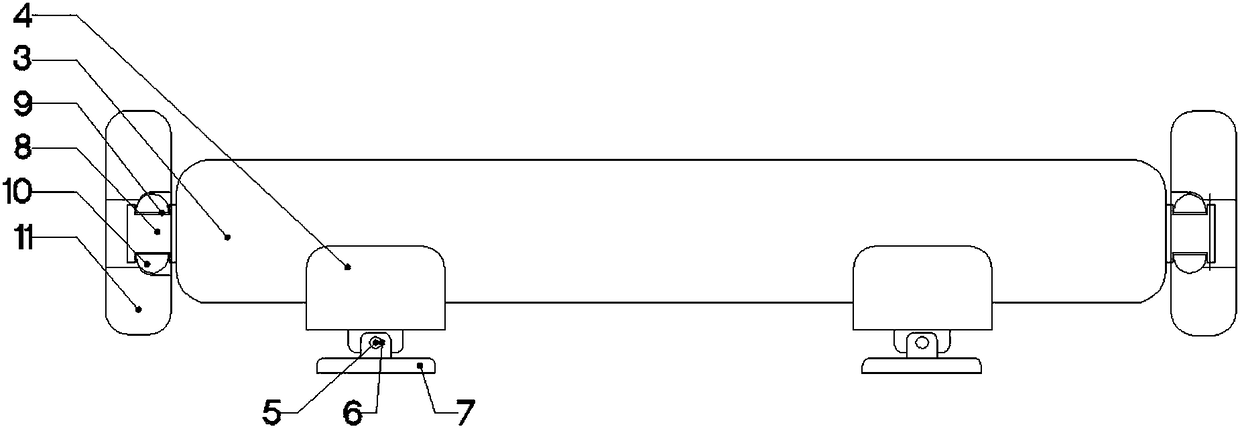

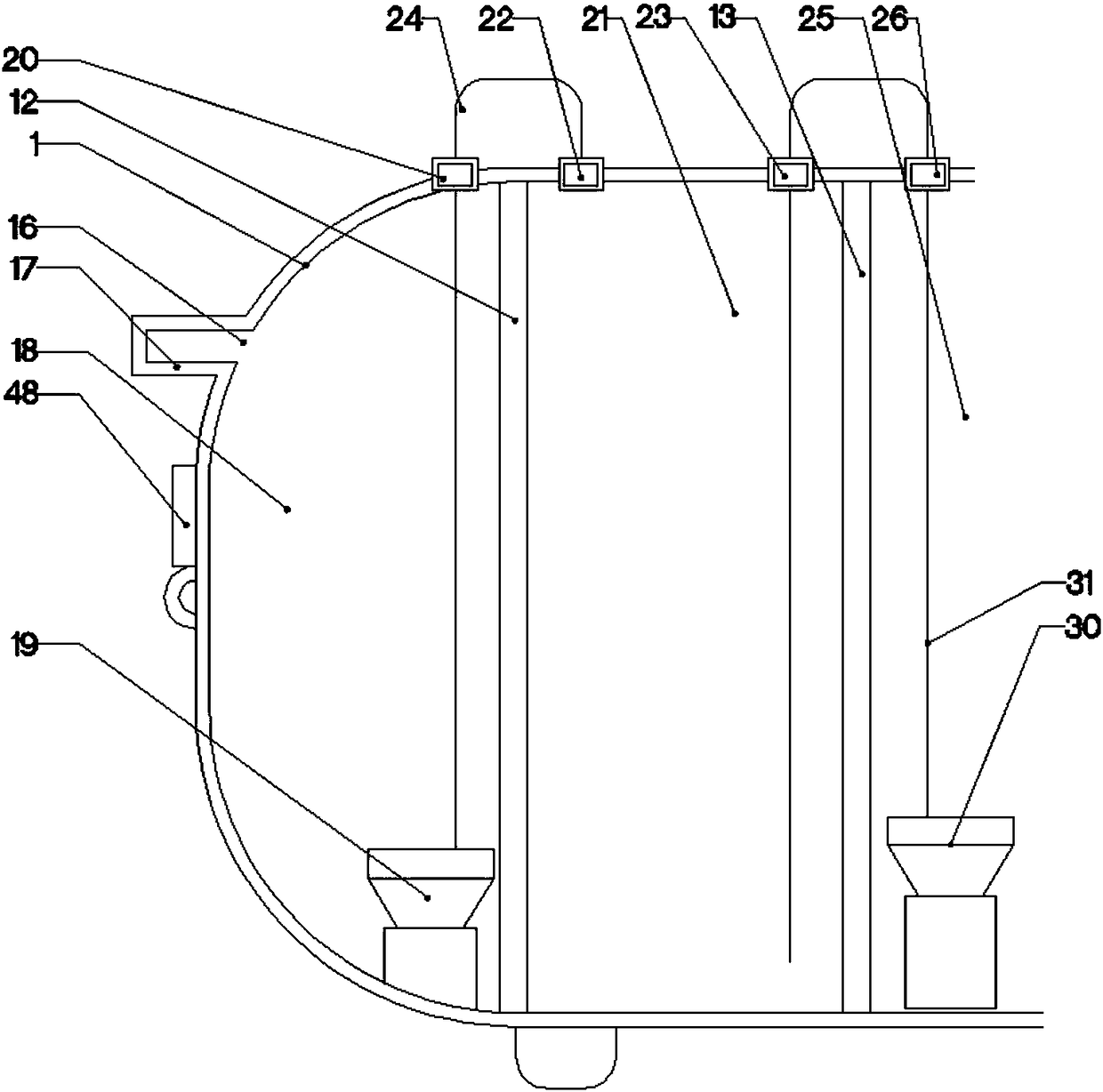

[0021] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-5 As shown, the filter tank body 1 is included, and it is characterized in that a moving device is provided under the filter tank body 1, and the moving device is fixedly connected to the filter tank body 1 by a traction ring 2 located at both ends of the filter tank body 1. . A rectangular support beam 3 located at both ends of the lower surface of the filter tank body 1 and fixedly connected to the filter tank body 1. A manual jack 4 located on the lower surface of the rectangular support beam 3 close to both ends with the telescopic end facing down and fixedly connected to the rectangular support beam 3. The circular through hole 5 located at the telescopic end of the manual jack 4 and fixedly connected with the manual jack 4 in the horizontal direction, the fixed shaft 6 located on the inner surface of the circular through hole 5 and fixedly connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com